The custom apparel industry is evolving rapidly, and DTF printing (Direct to Film) is emerging as a game-changing technology for producing high-quality, vibrant prints on various fabrics. In this guide, DTF printing is fully explained, from how transfers work to the benefits of using gang sheets for efficient production.

Whether you’re a business looking for reliable custom prints or a brand interested in high-volume output, DTF heat transfer technology offers superior color vibrancy, durability, and versatility.

In this guide, we’ll cover:

✅ What is DTF? Understanding the process and benefits

✅ DTF transfer sheets & heat transfers – How they work

✅ DTF gang sheets – Why they’re essential for cost-effective printing

✅ How DTF compares to other printing methods

What is DTF Printing?

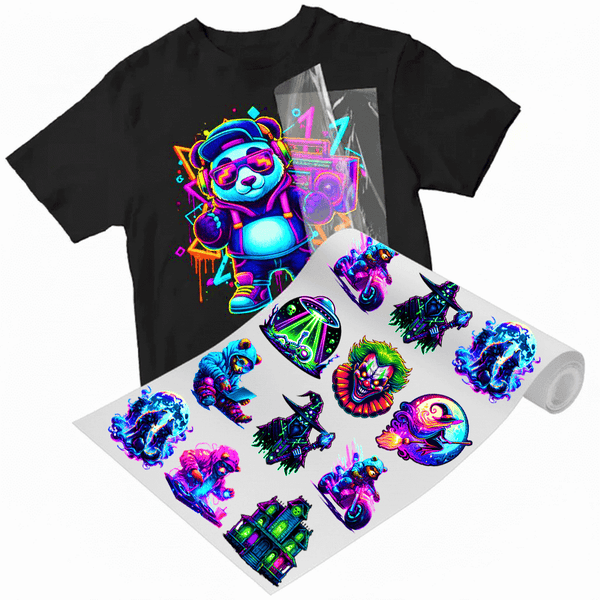

DTF (Direct to Film) is a heat transfer process that involves printing a design onto a specialized film, coating it with adhesive powder, and heat pressing it onto fabric. Unlike traditional printing methods, DTF transfers do not require pretreatment and work on a wide range of materials, including cotton, polyester, blends, and more.

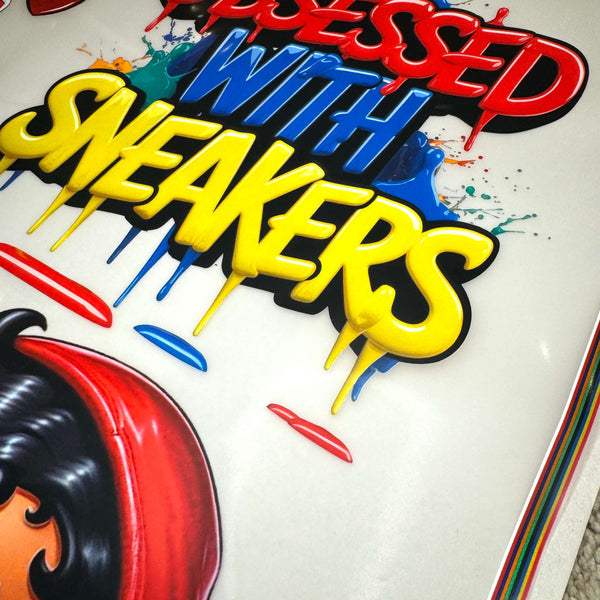

The DTF process creates long-lasting, vibrant designs that withstand multiple washes while maintaining their original look and feel.

DTF Meaning: Breaking It Down

The term DTF stands for Direct to Film, describing the process of printing a design onto a transfer film, applying an adhesive coating, and then using a heat press to transfer it onto fabric. This eliminates the need for screens, cutting, and weeding, making it an efficient and scalable printing solution.

How Does DTF Heat Transfer Work?

The DTF heat transfer process involves several key steps that ensure high-quality, durable prints.

Step 1: Printing on DTF Transfer Sheets

The process starts by printing the design onto a DTF transfer sheet using a DTF printer. The printer uses CMYK inks along with a white ink layer to create a full-color, high-opacity image.

Step 2: Applying DTF Powder

Once printed, DTF powder (hot melt adhesive powder) is evenly coated onto the printed design. This powder acts as an adhesive that will bond the print to fabric during heat pressing.

Step 3: Curing the Powder

The DTF transfer sheet is then placed in a curing oven or heat press to melt the powder, activating its adhesive properties.

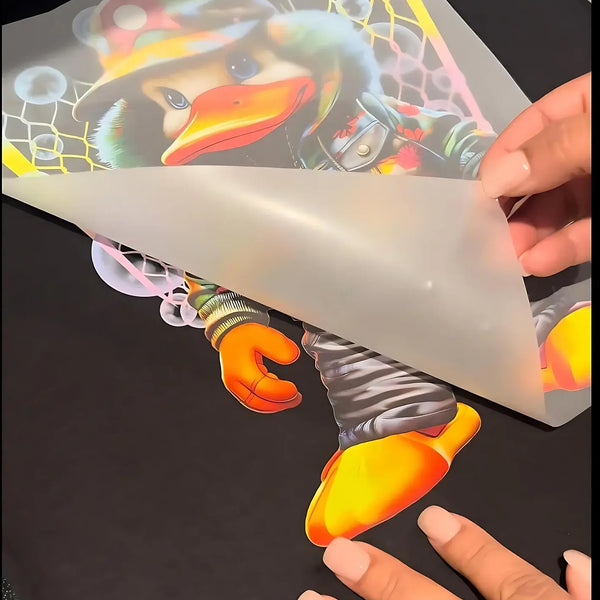

Step 4: Heat Pressing the Design onto Fabric

The prepared DTF transfer sheet is placed onto the fabric, and a heat press applies heat and pressure to permanently bond the print to the garment.

Step 5: Cold Peel for a Professional Finish

After cooling, the film is peeled away, leaving behind a smooth, vibrant, and highly durable design.

✅ No weeding or cutting required

✅ Transfers work on multiple fabric types

✅ Full-color, high-detail designs

What Are DTF Transfer Sheets?

DTF transfer sheets are pre-printed transfer films designed for direct application onto fabric. These sheets allow businesses to order custom prints in bulk and heat press them onto apparel as needed.

Benefits of Using DTF Transfer Sheets:

✔ Fast and efficient production – No setup time like screen printing

✔ No pretreatment needed – Unlike DTG, which requires pretreated fabric

✔ Compatible with various materials – Works on cotton, polyester, blends, and more

✔ High durability – Maintains color vibrancy and withstands repeated washes

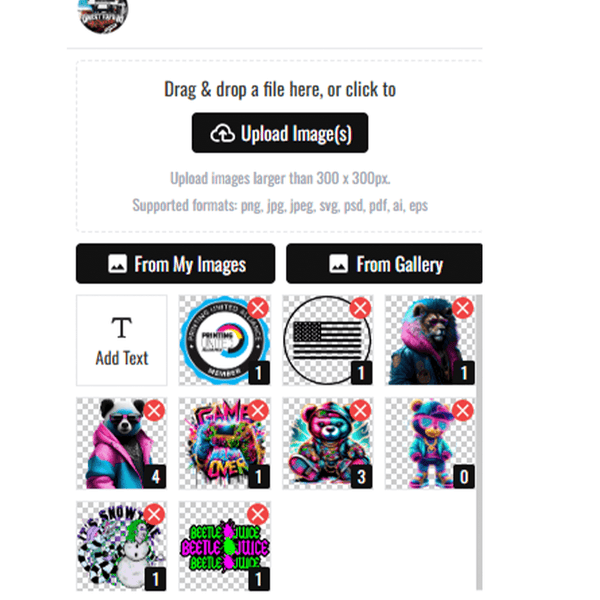

If you’re looking for bulk transfer options, pre-printed DTF transfer sheets are a cost-effective way to scale production while maintaining consistent quality.

DTF Gang Sheets: Maximizing Efficiency and Cost Savings

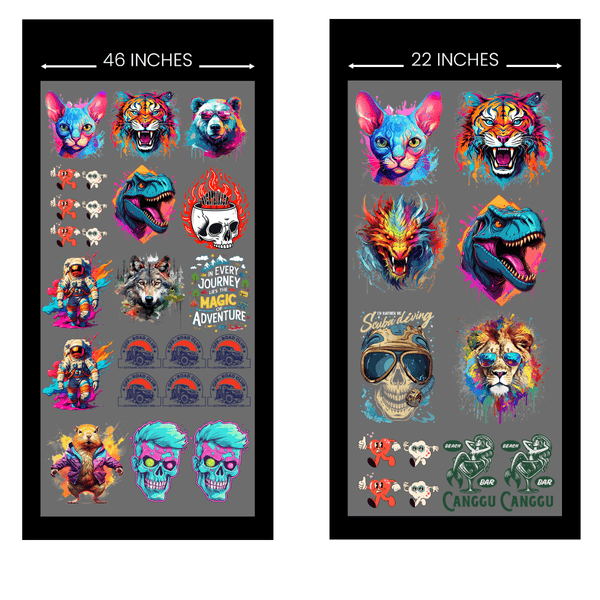

One of the biggest advantages of DTF printing is the ability to use DTF gang sheets to optimize material usage and reduce printing costs.

What is a DTF Gang Sheet?

A custom DTF gang sheets fast reliable transfer printing is a large transfer sheet containing multiple designs arranged to maximize space efficiency. Instead of printing one design per sheet, businesses can print multiple logos, graphics, or patterns on a single sheet, reducing waste and saving money.

Why Use DTF Gang Sheets?

✔ More designs per print – Lower cost per transfer

✔ Perfect for bulk printing – Ideal for businesses selling custom merchandise

✔ Efficient use of materials – Reduces excess waste and production time

Whether you’re producing branded apparel, team uniforms, or promotional merchandise, DTF gang sheets allow maximum output with minimum cost.

How Does DTF Printing Compare to Other Methods?

DTF vs. Screen Printing:

🔹 DTF requires no screens, making it ideal for small to medium print runs.

🔹 Screen printing is best suited for large bulk orders but has high setup costs.

DTF vs. DTG (Direct to Garment):

🔹 DTF does not require pretreatment, unlike DTG printing.

🔹 DTG works best on cotton, whereas DTF works on multiple fabrics.

DTF vs. Vinyl Heat Transfers:

🔹 DTF transfers are full-color with intricate details, while vinyl is limited in colors.

🔹 No weeding required for DTF, while vinyl must be cut and weeded manually.

If you’re looking for high-quality, vibrant, and durable prints without the limitations of traditional printing methods, DTF heat transfers are the perfect solution.

Why Choose DTF Printing for Your Custom Apparel?

DTF printing is quickly becoming the go-to solution for businesses looking for:

✅ Bright, vivid, and durable designs

✅ No setup time or expensive screens

✅ Compatible with a variety of fabrics

✅ Long-lasting, stretch-resistant prints

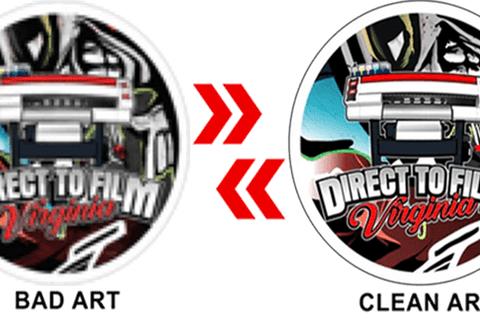

At DTF Virginia, we specialize in high-quality DTF transfer sheets and custom gang sheets that provide exceptional results for businesses, brands, and independent apparel creators.

Final Thoughts

DTF printing is changing the custom apparel industry by offering fast, durable, and vibrant prints that work on multiple fabric types. Whether you need DTF transfer sheets for bulk printing or custom DTF gang sheets, this technology delivers superior results compared to traditional methods.

Ready to upgrade your printing process? Explore our selection of high-quality DTF transfers today!