Ever printed a shirt and wondered, “Okay, but how long is this thing gonna last?”

Here’s the quick answer:

A well-made DTF (Direct-to-Film) transfer can last between 50 and 100 washes when pressed and cared for properly.

Let’s break down what really affects DTF print life, how to make your transfers last longer, and why it’s quickly becoming the go-to method for print shops and small brands.

What Is DTF Transfer Durability?

Let’s start simple.

When we talk about “durability” in printing, we’re talking about how well your design holds up over time after washes, wear, stretch, and exposure to sunlight.

It’s not just about the colors staying bright.

A durable print means:

-

No cracking

-

No peeling

-

No fading

-

And no stiff, plasticky feel after a few washes

Think of durability as how long your print lasts, how flexible it stays, and how well it keeps its color. If your shirt still looks great and feels soft after dozens of washes, that’s true durability.

So when someone says their DTF prints “last forever,” what they really mean is that the ink, adhesive, and fabric are working together perfectly.

Are DTF Transfers Durable?

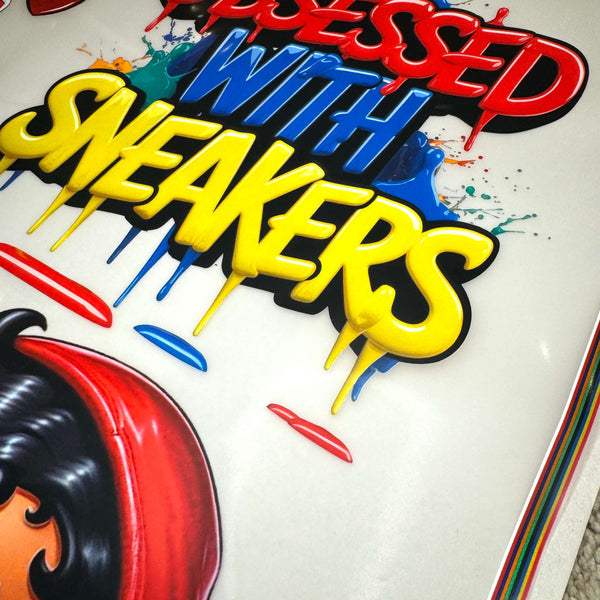

Yes, DTF transfers are extremely durable. DTF printing has changed the game when it comes to long-lasting designs.

-

The pigment inks are fade-resistant.

-

The adhesive powder melts and bonds into the fabric’s fibers.

-

The print layer stays flexible, not brittle or thick.

-

And unlike vinyl, DTF doesn’t sit on top of your shirt it bonds into it.

That combination makes DTF transfers ideal for both small custom orders and bulk runs. Whether it’s cotton tees, polyester jerseys, or canvas totes, DTF can handle them all.

How Long Do DTF Transfers Really Last?

When pressed and cared for properly, DTF prints can easily last for 50 to 100 washes.

Some high-quality transfers even push past that mark.

Here’s what determines that number:

-

The film, ink, and adhesive you use

-

Your heat press technique

-

And most importantly, how the customer washes the garment

If you’re using top-tier materials and applying them correctly, your DTF prints will stay soft, flexible, and colorful for years.

In other words, your customers won’t be calling you in a month complaining that their logo peeled off.

What Factors Affect DTF Transfer Durability?

Lets break down the factors that affect the durability of your DTF Transfers.

Quality of the Materials:

Durability starts with your materials. If the film, ink, or powder isn’t high quality, your print won’t last, no matter how good your press is.

-

PET Film (Transfer Film):

A clean, evenly coated film ensures smooth ink adhesion and flawless peeling.

Cheap, uneven film? Expect rough textures and early cracking. -

Pigment Inks:

Look for inks with strong UV and wash resistance. Premium inks stay bright even after 50+ washes. -

Adhesive Powder:

Fine-grain adhesive melts evenly and bonds tightly to fabric. The wrong powder can make prints stiff, brittle, or prone to peeling.

Heat Press Settings

Even perfect materials won’t last if your heat press setup is off. Temperature, time, and pressure must all be dialed in for a strong, lasting bond.

-

Temperature: 300–320°F (150–160°C)

-

Time: 10–15 seconds (depends on film and fabric)

-

Pressure: Firm and even across the platen

Too cool, and the adhesive won’t melt properly. Too hot, and you’ll overcure the ink or scorch the fabric.

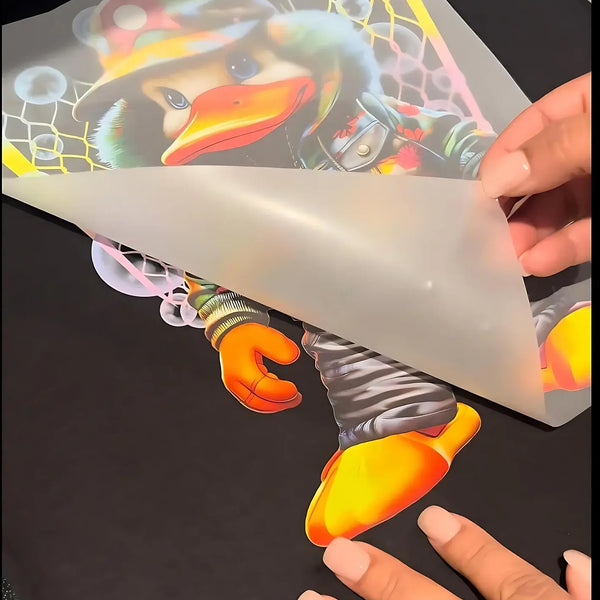

Also, follow your manufacturer’s peel method (hot, warm, or cold).

Peeling at the wrong time can lift edges or cause bubbles that reduce print life.

DTF Virginia Tip: Do a small corner peel test. If it comes off cleanly and the print looks glossy and bonded, your settings are right on target.

Fabric Type

Not all fabrics interact with DTF the same way. The material under the print affects adhesion, flexibility, and long-term wear.

-

Cotton & Cotton Blends: Great adhesion, soft feel, and vivid color output.

-

Polyester & Synthetics: Work well with DTF but need careful heat control to prevent scorching.

-

Stretch Fabrics (Lycra, Spandex): Can cause cracks if you use rigid adhesives. Use flexible powder blends for stretchability.

Design Style and Structure

Your design layout affects how durable your print turns out. Large, connected shapes hold better than small, delicate elements. Because thin lines, isolated letters, and tiny gaps create weak adhesion points that lift sooner during wear and washing.

If your artwork includes intricate details, apply a second light press (about 5 seconds) after peeling. This re-bonds the film and strengthens edges for longer life. Think of it as giving your print a little “armor layer.”

DTF Transfers Washing and Care Routine

Even the best-pressed DTF print can fail with the wrong wash routine.

That’s why post-care is everything.

-

Wait 24 hours before the first wash

-

Turn garments inside out

-

Use cold or lukewarm water on a gentle cycle

-

Skip bleach, strong detergents, and fabric softeners

-

Air dry whenever possible (or tumble dry on low)

-

Never iron directly on the print

Environmental Exposure

Exposure to sunlight, moisture, or friction can shorten print life.

For example:

-

Constant UV exposure may slightly fade colors over time.

-

Heat and humidity can soften adhesive bonds.

-

Repeated rubbing (like backpack straps or work tools) can cause wear on detailed prints.

Store DTF garments in a cool, dry place.

For outdoor or heavy-duty workwear, use UV-stable inks or darker shirts to minimize fading.

DTF vs Other Printing Methods Durability

| Feature | DTF (Direct-to-Film) | DTG (Direct-to-Garment) | HTV (Heat Transfer Vinyl) | Screen Printing |

|---|---|---|---|---|

| Wash Durability | 50–100 washes | 30–40 washes | 40–50 washes | 50+ washes |

| Stretch Resistance | High flexibility | Moderate | Good but stiff | Moderate |

| Weather Resistance | High | Moderate | High | High |

| Abrasion Resistance | High | Low–Moderate | Moderate | High |

| Feel on Fabric | Soft & flexible | Very soft | Slightly raised | Varies |

Why Choose DTF Virginia for Your DTF Transfers

DTF print durability comes down to materials, method, and care and that’s what we do best at DTF Virginia.

We use high-quality inks, powders, and PET films for strong adhesion and long-lasting color. Our transfers are built to handle repeated washes, daily wear, and tough conditions without cracking or fading. Check our collection today!

Frequently Asked Questions (FAQ)

Can I iron over a DTF design?

Not directly! Turn the shirt inside out or place a protective sheet over the print before ironing.

What is the lifespan of a DTF transfer?

Between 50–100 washes, depending on print quality and care. With gentle washing, they can last even longer.

Do DTF transfers crack?

Not if you use quality powder and film. Cracking usually happens when the print is overcured or stretched too much.

Is DTF print long-lasting?

Yes! DTF prints are known for staying soft, flexible, and colorful after dozens of washes.

Are DTF transfers permanent?

They’re not technically permanent, but they’re as close as it gets. With proper application, DTF designs can last for years.