DTF printing is quickly becoming one of the most popular methods for bringing creative designs to life. By standing out from traditional methods of printing, such as screen printing and digital printing, Direct To Film (DTF) printing provides a unique opportunity for businesses to get their branded apparel, signage, and products out in the world. But what are the advantages of DTF printing? It's time to find out!

7 Astounding Advantages of DTF Printing

DTF printing lives up to the hype as the most efficient and versatile method of printing available. It has revolutionized how businesses create their designs and apparel, making bringing truly unique products to market easier than ever. Here are some of the key benefits of DTF printing that businesses need to know.

Easy DTF Printing Process

Here is the beauty of DTF printing: its simplicity. Not only is the entire process easy from start to finish, but the actual printing time is also speedy compared to other types of apparel printing methods. It is a maximum advantage of DTF printing for businesses with a tight turnaround time for apparel needs. You need to follow this process:

- Design Preparation: Create the desired digital design using graphic design software such as Adobe Illustrator, Photoshop, or CorelDRAW. Ensure that the design is in the proper size and format for the intended print area on the garment.

- Film Printing: Load the DTF printer with specialized Direct-to-Film ink and a compatible PET film. Print the design onto the film. The printer will first lay down a layer of white ink, followed by the full-color design on top.

- Applying Adhesive Powder: Now, evenly apply a layer of adhesive powder to the surface of the ink. The powder can help the ink adhere to the garment during heat transfer. Remove any excess powder by gently shaking the film.

- Heat Press Preparation: Preheat the heat press to the recommended temperature and time settings for the specific type of garment and ink being used. Place the garment on the heat press platen, ensuring it is smooth and wrinkle-free.

- Transfer Process: To apply the design on the garment, place the printed film face-down onto the garment and align it in the desired position. Then, use a heat press by applying heat and pressure. Then remove the film from the garment carefully to uncover the completed design.

Durability and Longevity for Long-Lasting Results

Why go for DTF printing vs DTG? The answer is simple; because of its incredible durability and longevity. As we know, the prints are applied to the fabric directly via film and ultimately become a part of it. This is because the ink used in DTF printing does not penetrate the fabric, making it more resistant to fading and damage.

Moreover, it won't crack, peel, or flake off the fabric like other printing methods. You can grab more customers with better-quality prints that last longer. If you want to order the best DTF printed apparel, hit dtfvirginia.com.

Environmental Benefits of DTF Printing

Is DTF Printing eco-friendly? The answer is yes! Direct-to-film printing is the most eco-friendly printing option available. This process does not require additional water or chemicals, significantly reducing its environmental impact.

DTF printing also uses less ink than other traditional printing methods and fewer resources overall, which helps reduce waste. Moreover, DTF printing does not generate any hazardous waste and is a safe and sustainable option for businesses.

If you want to reduce your carbon footprint while still creating unique prints, DTF printing is the perfect solution.

Advanced Printing Capabilities with DTF Printing

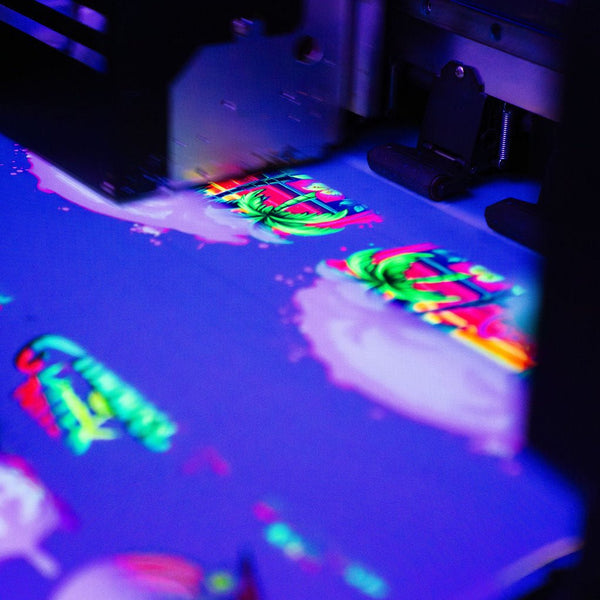

Another essential advantage of this beauty is its ability to produce high-quality, vibrant prints. This method uses advanced inkjet technology to print directly onto a special film, which is heat-pressed onto the fabric. The result is a stunning, high-resolution print that's not only visually appealing but also durable.

It is perfect for businesses looking to make eye-catching prints that really stand out from the crowd. Furthermore, unlike many traditional printing methods, there is no need for multiple screens or complex setups when using DTF printing.

Cost and Time-Efficient Printing

No more searching for What are the benefits of DTF printing? Because DTF printing offers the most cost and time-efficient way of creating high-quality prints. Simply buy the film, load it into the printer, and you are ready to go.

The printing process is fast and easy, which means businesses can quickly produce a large number of prints in a short amount of time. Moreover, companies can print multiple designs on one roll of film to save even more time. This allows for quick mass production, making this method incredibly cost-effective for businesses that need to produce a lot of prints in a limited amount of time.

No More Rough Patches

Traditional printing methods like screen printing often leave a rough feel on the fabric due to the thick layer of ink applied. In contrast, DTF printing creates a soft, smooth finish that's comfortable to wear.

Usually, DTF Inks SUB-T101 is used in DTF printing which is thinner and more flexible, which means it can easily conform to the fabric's texture without creating a stiff or bulky feel. Plus, the prints are durable and designed to last through multiple washes without fading or peeling. Isn't the best advantage of DTF printing?

Greater Design Flexibility

With DTF printing, 'the sky's the limit' when it comes to design possibilities. Unlike other methods that may restrict your creativity due to color limitations or the inability to print intricate details, DTF printing offers unparalleled design freedom.

You can print complex patterns, gradients, and even photographs with ease. For example, if you want to print a logo with multiple colors, you can easily do so without worrying about paying extra for each color.

Plus, DTF works on various fabric types, including cotton, polyester, and blends, giving you even more options for your creations. Isn't it great?

DTF Printing- Future of Textile Printing

DTF printing is undoubtedly changing the landscape of textile printing because of its efficiency, cost-effectiveness, and excellent results. With this, businesses can quickly create high-quality prints that last longer than ever with the help of advanced inkjet technology.

In the textile industry, products like t-shirts, hoodies, bags, and more can be created with this technique. Easy customization includes simultaneously printing multiple images and colors on different products without changing the inks or setup. We are expecting the future of textile printing to be extremely bright, thanks to DTF printing.