Ever since the invention of printing, designers have sought ways to create high-quality, unique, and creative designs that captivate audiences. From screen printing to embroidery, the options are endless. However, two techniques stand out in modern apparel printing:

Direct-To-Film (DTF) and Direct-To-Garment (DTG).

Both offer distinct advantages and disadvantages, making it difficult to determine which is best for your needs. In this guide, we’ll compare DTF and DTG to help you decide which is the superior choice.

How Do DTF and DTG Printing Work?

Before diving into the specifics, let’s get a brief overview of each method.

What is Direct-to-Film (DTF) Printing?

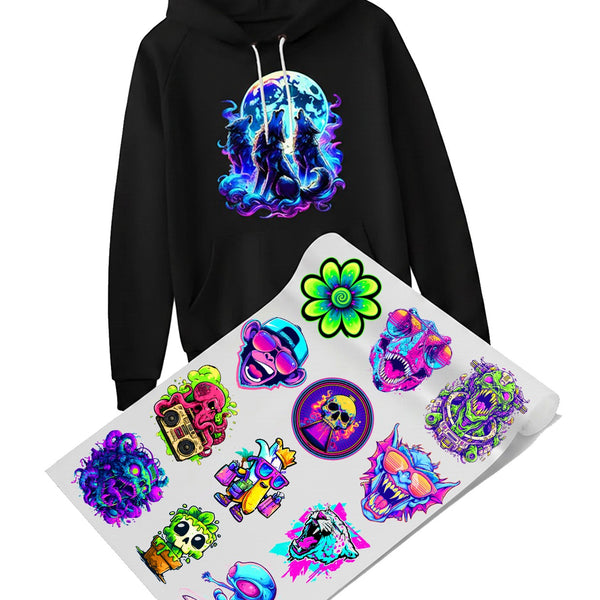

DTF printing involves printing a design onto a specialized film, which is then heat-pressed onto the fabric. This method:

✅ Works on cotton, polyester, blends, and other fabrics

✅ Produces durable prints that resist fading

✅ Excels at intricate designs with fine details

✅ Ideal for t-shirts, hoodies, hats, and tote bags

What is Direct-to-Garment (DTG) Printing?

DTG printing is a more established digital process that directly prints onto garments using specialized inkjet printers. This method:

✅ Produces smooth color gradients and detailed prints

✅ Works best on 100% cotton and light-colored fabrics

✅ Quick turnaround time for small-batch orders

✅ Best suited for high-detail, full-color prints

DTF vs. DTG: Key Differences

Now that we understand how they work, let’s compare DTF and DTG based on seven critical factors.

1. Ease of Maintenance

DTF Maintenance

🛠 Requires replacing films, cleaning printheads, and routine ink replenishment.

🛠 Low-maintenance compared to DTG.

DTG Maintenance

🛠 Requires regular cleaning of printheads and dampers.

🛠 Ink dries quickly and clogs if not used regularly.

🏆 Winner: DTF – Less maintenance required.

2. Durability & Longevity

DTF Durability

✔️ Highly durable prints that withstand multiple washes.

✔️ Resistant to cracking, peeling, and fading over time.

DTG Durability

❌ Less durable; prints may crack or fade after multiple washes.

❌ Often requires touch-ups or reprints.

🏆 Winner: DTF – Longer-lasting prints.

3. Color Vibrancy

DTF Color Quality

🌈 Vibrant, highly pigmented colors.

🌈 Can print on both light and dark fabrics.

DTG Color Quality

🌈 Uses CMYK inks, allowing up to 16 million colors.

🌈 Performs best on light-colored garments.

🏆 Winner: Tie – Both offer excellent color vibrancy.

4. Fabric Compatibility

DTF Versatility

✔️ Works on cotton, polyester, blends, leather, and more.

✔️ Ideal for hats, bags, hoodies, and accessories.

DTG Versatility

❌ Works best on 100% cotton.

❌ Requires pre-treatment for dark fabrics.

🏆 Winner: DTF – Works on more fabric types.

5. Print Quality Comparison

DTF Print Quality

📌 Sharp details and smooth gradients.

📌 Great for small and large orders.

DTG Print Quality

📌 Excellent photo-quality prints.

📌 Best for complex, multicolor designs.

🏆 Winner: Tie – Both offer high print quality depending on the use case.

6. Production Time & Scalability

DTF Production Time

🚀 Faster for bulk printing – multiple transfers at once.

DTG Production Time

⏳ Slower – prints one garment at a time.

🏆 Winner: DTF – More efficient for high-volume production.

7. Startup Costs

DTF Costs

💰 Lower initial investment than DTG.

💰 Requires film and heat transfer materials.

DTG Costs

💰 Higher upfront costs due to expensive printers.

💰 Ink costs can add up over time.

🏆 Winner: DTG – More cost-effective for small orders.

Pros & Cons of DTF and DTG Printing

✅ Pros of DTG Printing

✔️ High-resolution, photo-quality prints

✔️ Large print area for bigger designs

✔️ Eco-friendly with water-based inks

✔️ Ideal for small-batch orders

❌ Cons of DTG Printing

❌ Limited fabric options (best for cotton)

❌ Requires pre-treatment for dark fabrics

❌ Slower production speed

❌ Higher ink costs

✅ Pros of DTF Printing

✔️ Works on many fabrics (cotton, polyester, blends)

✔️ Vibrant colors with long-lasting durability

✔️ Lower production costs

✔️ No pre-treatment needed

❌ Cons of DTF Printing

❌ Smaller print area than DTG

❌ Requires extra transfer step

Final Verdict: Which Printing Method is Best?

Based on overall technical superiority, DTF printing takes the crown! 🏆

✅ DTF is best for:

- Businesses printing on multiple fabric types

- Bulk orders requiring fast turnaround

- Long-lasting, vibrant prints

✅ DTG is best for:

- Small-batch orders with complex color designs

- Eco-conscious brands using water-based inks

- Photographic-quality prints on cotton

Ultimately, the best choice depends on your specific needs, budget, and business goals. Understanding the differences between DTF and DTG ensures you select the most suitable printing method.

Get High-Quality DTF Transfers Today!

🚀 Ready to start printing with DTF? Explore our premium DTF Transfers and create stunning, durable prints for your business!