Do you have a printer that can create unique, vibrant designs without the hassle of dealing with traditional transfer paper, ink, and toner? If not, then you should consider a UV direct-to-film printer. It encompasses the benefits of heat transfer printing, also known as DTF, with the added bonus of UV curing.

Today most digital printing techniques utilize this kind of technology to achieve professional results without compromising quality. UV DTF is the go-to choice for all types of businesses, from leather and metal to ceramic. Let's explore what UV DTF printing entails and how it works.

What are UV DTF Transfers?

UV DTF transfers are a type of Direct to Film (DTF) transfer that utilizes UV light curing to fix the colors and designs onto a substrate. It means that the colors and designs are literally printed directly onto a material rather than using traditional inks or toners. UV DTF has entirely a different mechanism as compare to traditional DTF printing.

The film is like a sticker created under the influence of ultraviolet light, meaning it is instantly cured and ready to go. This method allows for printing intricate designs and photorealistic images on a wide range of materials, including textiles, wood, glass, metal, and more, except fabric.

No matter what kind of substrate you're working with, UV DTF is the most reliable and versatile method for printing unique designs.

Benefits of UV DTF Printing

UV DTF printing offers several advantages over traditional printing methods:

- Versatility: UV DTF printing is used on various materials, including textiles, wood, glass, and metal. This makes it ideal for multiple applications, from custom apparel and promotional products to signage and home décor.

- High-Quality Prints: The printing process produces vibrant, high-resolution prints with sharp details and accurate color reproduction. This enables the creation of intricate designs and photorealistic images that are impossible with other printing methods.

- Eco-Friendly: UV DTF printing generates minimal waste and uses environmentally friendly inks that do not contain harmful solvents or VOCs (volatile organic compounds). Additionally, the UV curing process eliminates the need for energy-consuming drying equipment.

- Efficiency: UV DTF printing allows for faster turnaround times and increased productivity without needing multiple screens or lengthy setup times. This makes it an attractive option for businesses looking to fulfill custom orders quickly and cost-effectively.

How Does UV DTF Printing Work?

The UV DTF printing process involves several key steps:

Step#1: Design Preparation

The first step in the UV DTF printing process is preparing your design using graphic design software. This typically involves creating or importing the desired artwork, adjusting colors and sizing, and converting the design into a print-ready format.

Step#2: Printing on Film

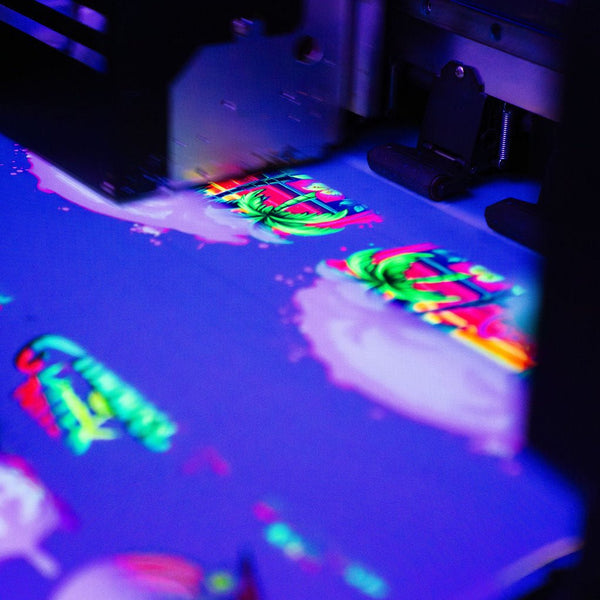

Next, the design is printed onto a specially coated film using a UV DTF printer. These printers use advanced inkjet technology to deposit tiny droplets of UV-sensitive ink onto the film. The ink is then immediately exposed to UV light, which causes it to cure and adhere to the film immediately. Here is everything you need to know about UV DTF printers.

Step#3: Adhesive Application

After printing the design and curing, an adhesive is applied to the printed side of the film. This adhesive ensures that the design will bond securely to the chosen substrate during the heat transfer process.

Step#4: Heat Transfer

The final step in the UV DTF printing process is transferring the design onto the desired material. You can do so by placing the film with the adhesive side facing down onto the substrate and applying heat and pressure using a heat press. The heat activates the adhesive, causing it to bond with the substrate and transfer the design.

Step#5: Peeling and Curing

After the completion of the heat transfer process, the film is carefully peeled away from the substrate. It leaves the design behind. If necessary, the substrate may be exposed to additional UV light to ensure that the ink is fully cured and the design is durable and long-lasting.

Step#6: Quality Testing

During the quality assurance process, samples of all prints are taken and tested for durability and accuracy. Any discrepancies between expected results and actual results will be addressed before the production run is released.

Exploring UV DTF Applications: What Items can be UV Printed?

UV DTF has various applications across various industries due to its versatility and high-quality output. Some examples of what you can use UV curing on include:

- Signage and Displays: UV DTF is an excellent choice for creating durable and eye-catching signs, banners, and displays for both indoor and outdoor use.

- Promotional Items: Customized promotional items like phone cases, water bottles, and keychains can be easily produced using UV DTF printing.

- Home Decor: Personalize your living space with UV DTF-printed canvas prints, wall art, and decorative items like coasters and trivets.

- Industrial Applications: This can also be used for printing on machine parts, electronic components, and other industrial items that require high durability and resistance to wear.

Final Words

To understand the process of UV DTF printing, it's important to remember that ultraviolet light is used to instantly cure the colors and designs onto a substrate. The versatility of this method allows for a wide range of applications in various industries and businesses.

Whether you are looking for signage, promotional items, or industrial components, UV DTF printing can help you achieve professional results without compromising quality.

With its high-resolution prints and quick turnaround times, UV DTF is an excellent choice for adding unique designs to any product or material. I hope you have learned more about UV DTF printing and how it can help your business.