Introduction

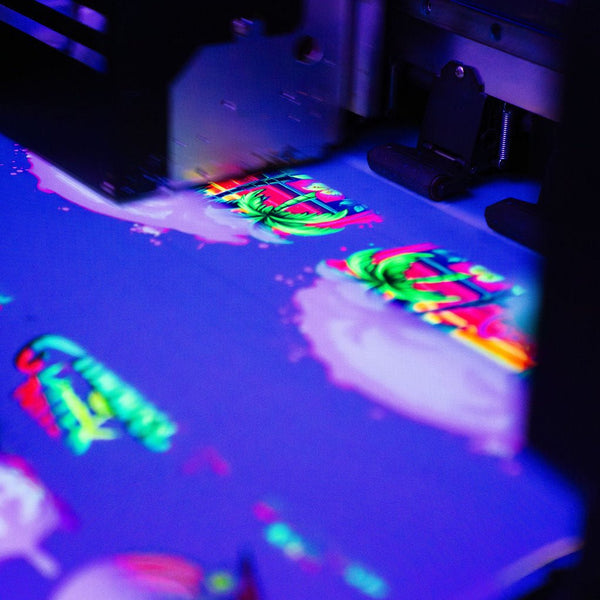

In the world of printing technology, Direct to Film (DTF) printing is emerging as a game-changer. This innovative method combines the intricacies of digital printing with the versatility of transfer techniques, allowing for vibrant, high-quality prints on a variety of materials. Whether you're a hobbyist looking to personalize your garments or a business seeking to expand your product offerings, understanding DTF printing can open new doors for creativity and commercial opportunity. This guide will delve into the intricacies of DTF printing, its advantages, applications, and how it compares to other printing methods.

Understanding DTF Printing

Definition of DTF Printing

DTF printing is a method that involves printing designs onto a special film which can then be transferred onto fabrics. Unlike traditional printing methods, DTF printing does not require intricate setup or long processing times, making it a more accessible option for many users. This technology has revolutionized the apparel industry by providing a cost-effective solution for producing intricate designs in bulk, catering to both small businesses and individuals looking to create custom apparel.

History and Evolution

The history of DTF printing can be traced back to traditional screen printing, which has been a dominant method in the textile printing industry for decades. However, advancements in digital printing technology have significantly enhanced the capabilities of printing techniques. Originally designed to facilitate the production of graphic-heavy designs and vibrant color applications, DTF emerged as a favored alternative to other digital printing options, such as Direct to Garment (DTG) and sublimation printing.

In recent years, there has been a growing demand for customizable and high-quality apparel. As a result, DTF printing gained popularity due to its efficiency, quality, and versatility across various materials.

How DTF Printing Works

DTF Printer Components

A typical DTF printer setup includes specialized print heads, heat transfer films, and adhesive powder. Each component plays a crucial role in ensuring the quality and durability of the printed designs.

- Print Heads: DTF printers are equipped with advanced print heads that allow for high-resolution image reproduction. These heads are capable of applying multiple colors simultaneously, producing vivid designs.

- Heat Transfer Film: The film used in DTF printing is specially coated to allow for ink adhesion. It acts as a medium where your designs are printed before they are transferred onto fabric.

- Adhesive Powder: After printing, a heat-activated adhesive powder is applied to the film. This powder bonds the ink to the film and ensures it adheres well when transferred to the fabric. The combination of ink and adhesive creates vibrant, long-lasting designs.

The Process of DTF Printing

The DTF printing process includes several critical steps:

- Design Creation: The process begins with creating a digital design. Many users employ graphic design software to produce images that meet their specifications.

- Printing on Film: Once the design is ready, it is printed onto the heat transfer film using the DTF printer. The print heads shoot the ink onto the film, and the heat transfer film absorbs the ink.

- Applying Adhesive Powder: After printing, the ink must be bonded with an adhesive powder. This step is crucial for ensuring the ink will adhere effectively to the fabric during the transfer process.

- Heat Transfer: Once the adhesive has been applied, the film is then placed onto the desired fabric. A heat press is used to apply heat and pressure, activating the adhesive and enabling the transfer of the design onto the fabric.

- Cooling and Peeling: Finally, the heat press is removed, and the film is peeled away, revealing a vibrant, durable print on the garment.

DTF Printing vs. Other Techniques

DTF vs. Sublimation

Both DTF and sublimation printing offer unique benefits, but they work on different principles. Sublimation printing relies on dye-sublimation technology, which involves turning solid dye into gas without passing through a liquid state. This method is highly effective on polyester fabrics and produces vibrant colors and a soft feel. However, sublimation is not suitable for cotton or dark-colored fabrics.

In contrast, DTF printing allows for a wider range of fabric types, including cotton, polyester, blends, and even some leather materials. This versatility makes DTF a more adaptable option for various applications. Additionally, the costs associated with DTF equipment and supplies are often lower than those for sublimation, making it an attractive alternative for small businesses and newcomers to the industry.

DTF vs. Traditional Methods

Unlike traditional methods like screen printing, DTF printing does not require extensive setup time, making it ideal for small runs and personalized projects. Screen printing typically involves creating separate screens for each color in a design, which can be labor-intensive and time-consuming. In comparison, DTF printing's digital approach streamlines the process, allowing for more efficient production.

Moreover, DTF printing can handle intricate designs and gradient color changes that may be challenging to achieve with screen printing. The flexibility in design application enables creators to experiment with various artistic styles without significant limitations.

Materials Needed for DTF Printing

DTF Transfer Paper

Choosing the right DTF transfer paper is crucial for the success of your printing projects. The transfer paper must be compatible with the DTF printing process and of high quality to ensure that colors are vibrant and the print adheres well to fabric. Generally, DTF transfer paper is designed to withstand the heat and pressure of the transfer process, resulting in a durable print.

When selecting transfer paper, consider factors such as:

- Compatibility with Inks: Ensure the transfer paper is designed for use with DTF inks to achieve optimal results.

- Finish Options: Decide if you prefer a glossy or matte finish based on the desired appearance of the final product.

- Weight and Thickness: Heavier transfer papers may be more durable, while lighter options could be easier to handle and apply.

Inks and Adhesives

The inks used in DTF printing are specifically formulated to provide rich color and durability. These inks are typically water-based, allowing for vibrant colors and intricate designs without the harsh chemicals often found in traditional printing inks. When sourcing inks, make sure they are compatible with your DTF printer to achieve the best results.

The quality of the adhesive powder is equally important. A premium adhesive will ensure that the design adheres effectively to the fabric, resulting in a long-lasting product. It is advisable to conduct tests using different brands of adhesives to find the one that provides the best results for your specific printing needs.

Applications of DTF Printing

Industries Utilizing DTF Printing

DTF printing is gaining traction in various industries, including:

- Fashion Industry: DTF printing allows fashion designers to produce intricate designs on garments quickly and cost-effectively, making it ideal for small fashion lines and custom apparel.

- Promotional Products: Businesses often use DTF printing for promotional items such as custom t-shirts, mugs, and bags. Its versatility allows for rapid production and high customization, catering to specific client needs.

- Merchandise: DTF printing is a popular choice for creating merchandise for bands, artists, and events, allowing for quick turnaround times and vibrant designs.

Common Use Cases

DTF printing offers a wide array of applications, including:

- T-Shirts: Custom printed tees are immensely popular, and DTF printing allows for high-quality designs at competitive prices.

- Hoodies: DTF's versatility makes it a great option for printing on heavier fabrics like hoodies.

- Bags and Accessories: With DTF printing, you can personalize tote bags, backpacks, and caps, expanding your product range.

- Specialty Items: DTF printing can also be employed for items like pillowcases, tablecloths, and banners, showcasing its adaptability.

Niche Markets for DTF Printing

The rise of DTF printing has facilitated the growth of niche markets, including personalized gifts for special occasions, such as custom shirts for birthdays, weddings, and family reunions. Its capabilities also support creative projects for DIY enthusiasts, allowing them to create customized apparel and craft items for themselves and their loved ones.

Advantages and Disadvantages of DTF Printing

Benefits of DTF Printing

Some of the primary advantages of DTF printing include:

- Cost Efficiency for Small Runs: DTF printing minimizes setup costs and allows users to produce small quantities without financial strain, catering to budding entrepreneurs and crafters. For more about DTF printing and its benefits for small businesses, check out this comprehensive guide from Coldesi.

- Versatility Across Different Materials: DTF printing can be used on various fabrics and surfaces, making it an excellent option for a wide range of projects.

- High-Quality, Long-Lasting Results: DTF prints are known for their vibrant colors and durability, ensuring that designs remain intact even after multiple washes.

- Less Waste: The DTF process produces minimal waste compared to traditional methods, benefiting both businesses and the environment.

Potential Drawbacks

While DTF printing boasts many benefits, there are some potential drawbacks to consider:

- Initial Investment in Equipment: Setting up a DTF printing operation can require a significant upfront investment in equipment and materials, which might be prohibitive for some individuals.

- Learning Curve and Maintenance Considerations: New users may face a learning curve when familiarizing themselves with the equipment and processes involved in DTF printing. Regular maintenance of printers and equipment is also necessary to ensure optimal performance.

- Cost of Supplies: Though DTF printing can be cost-effective for small runs, the ongoing costs of specialized transfer films, adhesives, and inks can add up over time.

Best Practices for Successful DTF Printing

Preparing Your Design

To achieve the best results with DTF printing, it's essential to prepare your design properly. Use graphic design software such as Adobe Illustrator or CorelDRAW to create designs that are high-resolution and suitable for printing. Pay attention to color profiles and ensure that the colors will translate accurately during the printing process.

Setting Up Your Printer

Properly setting up your printer is crucial for quality output. Make sure to follow the manufacturer’s instructions to calibrate your printer. Regular maintenance, including cleaning the print heads, will help avoid issues that can arise during the printing process.

Post-Printing Techniques

After completing the printing and transfer processes, take the time to review the results. Proper heat pressing ensures that the design adheres correctly. Investing in a high-quality heat press can make a significant difference in the durability and appearance of your finished product.

Future of DTF Printing

Innovations on the Horizon

As DTF printing technology continues to evolve, innovations in inks, adhesives, and equipment are on the horizon. Companies are working on creating even more efficient and environmentally friendly products, which could further enhance the accessibility and appeal of DTF printing for both businesses and crafters.

DTF Printing in the Broader Context of Digital Printing

DTF printing represents an important evolution in the digital printing landscape. As customer demand for custom designs grows, DTF printing provides an effective solution to keep pace with the changing market. With ongoing technological advancements, the future of DTF printing looks promising, with ample opportunities for growth and innovation.

Conclusion

As you venture into the world of DTF printing, it's essential to understand its potential and limitations. Whether you're looking to start a new project or enhance your business offerings, DTF printing presents an exciting opportunity for creativity and innovation. The accessibility and versatility of DTF printing make it a valuable addition to personal and commercial endeavors, creating a space where imagination can flourish.

Call to Action

Are you ready to dive into the world of DTF printing? We encourage you to explore its potential and share your experiences or questions. Whether you're a hobbyist or a business owner, DTF printing can take your creative projects to the next level. Start your journey today!