UV DTF transfers are rapidly changing Norfolk's custom apparel and product landscape. These advanced transfers provide exceptional color, resilience, and flexibility that many older methods cannot easily replicate. If you want to enhance your t-shirt designs or launch a custom merchandise business in Norfolk, exploring UV DTF transfers could be a very beneficial step.

What Are UV DTF Transfers?

UV DTF signifies Ultraviolet Direct to Film. This printing technique employs specialized UV-curable inks to produce vibrant designs on a film. These resulting dtf transfer sheets are then ready for application to a multitude of fabrics and even hard surfaces.

The core of dtf printing involves printing a design onto a specific carrier film, which is then often coated with an adhesive powder. Subsequently, UV light cures the ink almost instantly, creating a durable and flexible transfer sheet ready for heat application or, in the case of UV DTF stickers, direct application.

This process results in a high-quality dtf heat transfer that is both robust and visually appealing. The technology allows for fine details and a broad color spectrum, making it an excellent choice for complex graphics. Many businesses find this an improvement over older heat transfers.

The Core Advantages of UV DTF Technology

Norfolk's active arts community and growing number of small businesses create an ideal environment for custom products. UV DTF transfers bring several key benefits compared to traditional printing methods, making them a popular choice for custom dtf work.

- Rich Colors: UV inks deliver exceptionally bright and vivid colors that stand out on any material, whether it's a color dtf design or a simple graphic.

- Lasting Quality: These transfers are built to endure many washes without showing signs of fading, cracking, or peeling, a significant feature for any dtf heat transfers.

- Material Versatility: They adhere effectively to a wide array of materials, including cotton, polyester, blends, leather, and even hard surfaces like wood, glass, and metal when used as uv dtf sticker products.

- Full Color Spectrum: Unlike methods like screen printing, UV DTF imposes no restrictions on the number of colors in a design, allowing for photorealistic prints.

- Comfortable Finish: The transfers are remarkably thin and pliable, leading to a soft texture on garments, much appreciated by end-users.

The ability to produce detailed, full-color designs without the complex setup of other methods is a major draw. This makes dtf transfers highly efficient for both small and large orders. The dtf heat application process is also straightforward with a reliable heat press.

Comparing UV DTF with Traditional Methods

Understanding how UV DTF stacks up against other decoration methods can help you make an informed decision. Here's a brief comparison:

|

Feature |

UV DTF Transfers |

Screen Printing |

Heat Transfer Vinyl (HTV) |

Sublimation Transfers |

|

Color Capability |

Full color, gradients |

Limited by screens (cost increases with colors) |

Limited by vinyl color, layering for multi-color |

Full color, gradients |

|

Fabric Compatibility |

Cotton, polyester, blends, leather, nylon (light & dark fabrics) |

Most fabrics, best on cotton |

Cotton, polyester, blends |

Polyester & poly-blends (light colors only for sublimation transfers) |

|

Durability |

High, good wash resistance |

Very high, can outlast garment |

Good, but can peel/crack over time |

Excellent, ink becomes part of fabric |

|

Feel on Garment |

Soft, thin |

Can be heavy with multiple colors |

Can feel like a layer on top |

No feel, ink dyes fibers |

|

Small Runs/Complexity |

Excellent, no setup per color |

Costly for small runs or many colors |

Good for simple, small runs; weeding complex designs is time-consuming |

Good for small runs, design complexity not an issue |

|

Hard Surface Application |

Excellent for uv dtf stickers |

Possible with special inks/processes |

Not typical |

Possible on specially coated hard surfaces |

This table shows that while methods like sublimation transfers are excellent for polyester, UV DTF offers broader compatibility, including dark garments and hard goods. Traditional heat transfer methods like HTV can be effective, but UV DTF often provides superior detail and feel for complex designs. Trucolor dtf options further enhance the color accuracy and vibrancy for demanding projects.

UV DTF in Norfolk: Transforming Local Customization

Local enterprises in Norfolk are increasingly recognizing the substantial benefits of uv dtf transfers. From independent artists to established apparel companies, many are adopting this technology for their customization requirements, particularly for dtf custom orders.

Imagine a local band wanting vibrant merchandise for their next show at The NorVa. With UV DTF, they can get full-color long sleeve shirts and dtf stickers printed quickly and affordably, even in small batches. This agility is transforming how Norfolk creatives approach merchandising.

UV DTF Transfers for Small Norfolk Businesses

For small businesses and startups in Norfolk, UV DTF technology presents an economical way to produce top-tier custom apparel and products. The absence of high setup costs for multi-color designs and the feasibility of small orders make it accessible. This allows businesses to experiment with various designs for dtf heat transfer sheet applications without significant initial investment.

A local artisan in the NEON District could use uv dtf sticker sheets to create unique branding for their handcrafted goods. They might design a uv dtf sticker sheet builder layout to get multiple designs on one sheet, maximizing value. These stickers can then be applied to packaging, products, or even sold separately, offering a new revenue stream. Similarly, creating glitter dtf transfers could add a premium option to their product line.

UV DTF Transfers for Larger Norfolk Operations

Larger businesses in Norfolk, such as corporate apparel suppliers or event management companies, also find considerable advantages with uv dtf transfers. The rapid production times and consistent output quality are well-suited for bulk orders of dtf heat transfers. This is especially true when using a gang sheet to maximize prints per sheet.

A Norfolk-based company organizing a city-wide festival could use UV DTF to produce promotional t-shirts, tote bags, and even custom signage. The ability to handle intricate, multi-color logos and graphics consistently across thousands of items ensures brand integrity. Options like trucolor dtf heat transfers can guarantee color matching for corporate clients.

Getting Started: Your UV DTF Journey in Norfolk

If you're prepared to explore uv dtf transfers for your Norfolk-based venture, here's a straightforward guide to begin. The process is accessible, and the results can be quite rewarding.

- Research and Find a Reputable Supplier: Seek out a reliable local or online supplier offering UV DTF transfer services. Look for positive reviews, examine samples of their transfer sheet quality, and inquire about their dtf printing capabilities. Some suppliers may even offer trucolor dtf transfer builder tools.

- Prepare Your Artwork: Develop a high-resolution digital design. UV DTF excels with detailed, multi-color artwork, so ensure your files are print-ready, often in PNG format with a transparent background. Consider using a vector service if your artwork needs refinement or conversion.

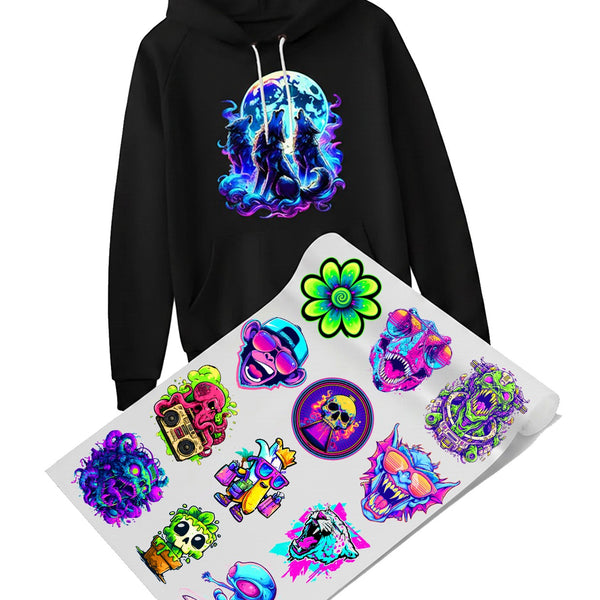

- Select Your Products: Determine which items you wish to customize. T-shirts, hoodies, hats, bags, and even hard goods like mugs or phone cases are suitable for UV DTF transfers or uv dtf stickers.

- Place Your Order: Submit your design files and product specifications to your chosen supplier. Discuss options like creating a custom dtf gang sheet to print multiple designs efficiently. Many suppliers have an online transfers builder or dtf transfer builder to simplify this.

- Apply the Transfers: If you are handling application, a quality heat press is essential. Follow the supplier's recommended settings for temperature, pressure, and time. Alternatively, many Norfolk suppliers offer application services. For uv dtf stickers, application is typically a peel-and-stick process after ensuring the surface is clean.

Designing for UV DTF: Tips for Great Results

Creating designs that translate well to UV DTF requires some attention to detail. Ensure your artwork has a minimum resolution of 300 DPI for clarity. Transparent backgrounds are crucial for the design to appear cleanly on the dtf transfer sheet.

Avoid extremely fine lines or tiny, isolated text elements, as these might not transfer or adhere as robustly. If your design skills are limited, or your logo is in a low-quality format, investing in a professional vector service can make a significant difference in the final print quality. They can convert pixelated images into scalable vector graphics suitable for any size of dtf heat transfer.

Working with Suppliers and Using Builders

Many modern DTF suppliers offer online tools like a sheet builder, gang sheet builder, or dtf transfers builder. These platforms allow you to upload multiple designs and arrange them on a single transfer sheet or gang sheet to maximize space and reduce cost per print. This is particularly useful for small businesses needing variety without high volume per design.

When using a heat transfer sheet builder or dtf heat transfer sheet builder, pay attention to the indicated printable area. Leave small gaps between designs for easy cutting. A uv dtf sticker sheet builder functions similarly, allowing you to create a sticker sheet with various dtf sticker designs.

Always communicate clearly with your supplier about your expectations for color dtf accuracy. If you require specific shades, discuss color matching possibilities. Some suppliers specialize in trucolor dtf, which focuses on precise color reproduction.

Exploring the Variety: Beyond Standard UV DTF

The world of DTF is not limited to standard color prints. Several specialty options can add extra appeal to your custom products.

Glitter DTF Transfers: Adding Sparkle

For those looking to add some dazzle, glitter dtf transfers are an excellent choice. These transfers incorporate glitter particles directly into the print, creating a sparkling effect that catches the light. Glitter dtf is popular for fashion apparel, spirit wear, and items needing an extra touch of glamour, such as gold glitter dtf transfers or other gold glitter effects.

Using a glitter dtf transfers builder can help you visualize how your designs will look with this effect. Gold glitter dtf is particularly sought after for its luxurious appearance. These are a step up from basic color custom dtf.

Fluorescent DTF Transfers: Making a Statement

If you want designs that truly pop, consider fluorescent dtf transfers. These use vibrant, neon inks that are incredibly bright under normal light and can even glow under blacklight. Fluorescent dtf is perfect for safety gear, event merchandise, or fashion items that aim to be noticed.

A fluorescent dtf transfer builder might be offered by specialized suppliers. You can create eye-catching fluorescent dtf heat transfers that make a bold statement. The fluorescent dtf heat application is similar to standard DTF.

Specialty Finishes like Gold Glitter DTF

Beyond general glitter, specific shades like gold glitter dtf offer a premium look. This can elevate a standard design, making it appear more high-end. Such finishes are often requested for special occasion wear or branded luxury items.

The richness of gold glitter can significantly enhance logos or text elements. When you view product samples with this finish, the quality difference is often apparent. It adds a tactile and visual element that standard inks cannot achieve.

The Rise of UV DTF Stickers for Hard Goods

UV DTF stickers are a specific application of UV DTF technology designed for hard, non-porous surfaces. Unlike garment transfers, these dtf stickers are typically applied directly without a heat press, functioning more like high-quality decals. They are incredibly durable, waterproof, and scratch-resistant.

Businesses can use a uv dtf sticker sheet builder to produce multiple uv dtf stickers for branding laptops, water bottles, phone cases, and more. This versatility opens up a vast market for custom promotional products beyond apparel. Creating a dtf sticker sheet with various designs is a cost-effective approach.

Understanding Gang Sheets for Efficiency

A gang sheet is a large sheet of transfer film onto which multiple designs are printed. This method is highly efficient as it maximizes the use of the film and reduces printing time per design. Suppliers often offer a gang sheet builder tool, allowing customers to arrange their custom dtf gang artwork themselves.

Using a dtf gang sheet builder means you can combine various sizes and shapes of designs onto one dtf gang layout. This is ideal for fulfilling multiple small orders or creating a diverse inventory of dtf heat transfer sheet designs. Companies offering tru color custom dtf gang sheets focus on maintaining color consistency across all designs on the sheet.

Whether it's a color custom dtf gang sheets for varied apparel or a sublimation gang sheet (though different technology, the concept of ganging designs is similar for efficiency), the principle is to optimize material usage. Many businesses rely on custom dtf gang sheets to keep their per-unit costs low. When you view product offerings from suppliers, ask about their custom gang sheets options.

The Bright Future of UV DTF in Norfolk

As more Norfolk businesses and individuals experience the advantages of uv dtf transfers, the demand for unique, high-quality custom items is set to grow. This technology unlocks new avenues for local artists, entrepreneurs, and established companies. The ease of creating custom dtf products is a significant factor in this growth.

Several print shops in Norfolk are already upgrading their equipment to include UV DTF capabilities. This local investment means quicker production times and potentially more competitive pricing for customers in the future. Access to a local dtf transfer builder or a specialized trucolor dtf transfer builder will become more common.

Technological Advancements and Trucolor DTF

The field of dtf printing is continually advancing. Innovations in ink formulations, film technology, and curing processes are improving quality and efficiency. Trucolor dtf systems, for instance, focus on achieving highly accurate and consistent color reproduction, which is vital for brands with specific color guidelines.

Expect to see trucolor dtf heat transfers and trucolor dtf heat applications becoming more prevalent as businesses demand higher fidelity in their custom products. These advancements ensure that the final dtf heat transfer sheet closely matches the digital design. Some international material sourcing for these advanced inks or films might involve pricing in currencies like eur ¬, although most local transactions for businesses in places like the islands usd or mainland US would be in USD.

Environmental Impact and Sustainability

UV DTF transfers are also notable for their more favorable environmental profile compared to some traditional printing methods. The UV curing process is energy-efficient and produces minimal volatile organic compounds (VOCs). Additionally, dtf printing generally results in less waste than screen printing, which involves significant water usage and chemical disposal.

A Norfolk-based environmentally conscious apparel brand successfully transitioned to using primarily UV DTF transfers. They noted a measurable decrease in material waste and an increase in customer interest due to the vibrant, durable, and more sustainably produced prints. Suppliers are also exploring more eco-friendly films and inks for uv dtf transfers and uv dtf sticker sheet products.

Tips for Long-Lasting UV DTF Applications

To achieve the best results and ensure longevity with uv dtf transfers for your Norfolk business, consider these practical tips. Proper application and care are important for customer satisfaction.

Application Best Practices

- Pre-press Your Garment: Always pre-press the garment for a few seconds in your heat press to remove moisture and wrinkles. This creates a smooth surface for the dtf heat transfer.

- Correct Temperature and Pressure: Follow your supplier's guidelines for heat press temperature, pressure, and pressing time. These settings can vary based on the specific transfer sheet and fabric.

- Peel Method: Understand whether your dtf transfers are a cold peel or hot peel. Peeling incorrectly can damage the transfer.

- Test First: If possible, test a small transfer on a scrap piece of the same material to confirm your settings.

Care Instructions for Garments

- Wait Before Washing: Advise customers to wait at least 24-48 hours before washing a garment with a new dtf heat transfer.

- Wash Inside Out: Washing garments inside out helps protect the transfer from abrasion.

- Use Cold Water: Cold water and a mild detergent are gentlest on dtf heat transfers.

- Avoid Bleach and Fabric Softeners: Harsh chemicals can degrade the print over time.

- Tumble Dry Low or Hang Dry: High heat from dryers can damage the transfer. Hang drying is often the best option.

- Do Not Iron Directly on the Print: If ironing is necessary, iron the garment inside out on a low setting, avoiding direct contact with the dtf transfer.

Communicating these care instructions to your customers can significantly extend the life of their custom dtf items. This attention to detail reflects well on your brand. It also applies to items like spangle transfers or even sublimation transfers which also benefit from proper care.

Conclusion

UV DTF transfers are truly reshaping the custom apparel and product industry in Norfolk. They present an optimal mix of quality, adaptability, and affordability that can benefit businesses of every scale, from solo entrepreneurs creating dtf sticker sheet designs to larger companies ordering custom gang sheets. Whether you are a budding startup or a well-known brand in Norfolk, leveraging uv dtf transfers could be the very thing your business needs to stand out and impress customers.

With their vibrant colors, lasting durability, and ability to work on diverse materials, dtf transfers open up many creative possibilities. Consider exploring glitter dtf transfers, fluorescent dtf transfer options, or the precision of trucolor dtf heat transfers. The technology is here, and Norfolk businesses are increasingly embracing it for everything from uv dtf stickers to full apparel lines.

Why not investigate how UV DTF transfers Norfolk services can help your projects? The positive impact on your product quality and customer satisfaction might be substantial. From utilizing a transfers builder for easy ordering to seeing your designs come to life with a heat press, the journey into dtf heat transfers is an exciting one.