Have you heard about ninja transfer and wondering why it’s so popular? Many are looking for ways to customize items. This ninja transfer is gaining traction in personalized apparel and other creative projects.

You want to know how it can help you achieve amazing custom designs without the hassle. It makes sense to look for something that’s effective, visually appealing and user friendly. The ninja transfer delivers on all three, simplifying customization.

What is a Ninja Transfer?

Let’s break down what a ninja transfer is. It’s a super efficient way to apply vibrant, detailed designs onto fabrics and other surfaces. It’s often a dtf transfer, known for its great quality and easy application process; many consider it a custom dtf.

These transfers, sometimes called ninja dtf transfers, come ready to press. That means the artwork is pre-printed on a special film, so you just need to apply it with heat. It’s like an advanced, high quality decal for apparel and other items.

The benefit of this system is it makes intricate, multi-color designs super easy to produce. You don’t need to have extensive printing experience to get professional results. That’s why it’s getting popular and why people are choosing ninja transfers.

Why Call It a Ninja Transfer?

You may ask about the name – why “ninja” transfer? Ninjas are known for their speed, precision and high effectiveness. This type of transfer, often a dtf transfer, has some of those qualities.

Firstly, application is quick. The process is fast, saving you time. That’s especially good for large batches or if you don’t want to wait long for results.

Secondly, the precision is amazing. These transfers dtf can capture very fine details and sharp lines. Your designs will look crisp and clear, like a ninja’s precise move.

Lastly, they integrate so well they seem to materialize. One moment you have a plain item; the next it has a design. The transfer adheres to the fabric seamlessly, like it’s part of the material itself.

The Tech Behind Your Designs: Inside a Ninja Transfer

Let’s look at the technology used in a ninja transfer. It most often uses the Direct-to-Film (DTF) printing process. This modern process is used to create high quality heat dtf transfers, which are the backbone of ninja transfers dtf. The process starts with a special printer. This machine uses water-based pigment inks to print your design directly onto a clear polyester film. A key feature is the white ink layer under the colors, so your prints will be vibrant and detailed even on dark colored fabrics.

After printing, a powder adhesive is applied to the still wet ink. This adhesive powder only sticks to the printed areas of the film. The film then goes through a heating process, which cures the ink and melts the powder, forming a durable and flexible transfer layer.

Once this curing stage is done, the transfer is ready. You can store it for future projects or apply it immediately. When you’re ready to customize your item, you simply use a heat press. The heat activates the adhesive and bonds the design to your item. After pressing, you peel away the film and your design is perfectly attached to the fabric.

This DTF method allows for full color, intricate designs without the hassle of cutting or weeding, which is common with vinyl. That’s a big time saver. Plus it’s compatible with many fabric types, making ninja transfer a versatile solution for your various creative projects and custom dtf needs.

Awesome Benefits of Ninja Transfer

Many reasons to use a ninja transfer for your custom projects. Many people love them because they offer great quality, convenience and versatility. Let’s look into some of the main benefits you can expect when using ninja transfers for your needs.

Amazing Print Quality

One of the biggest benefits is the print quality. Ninja transfers, especially those using DTF technology, can produce super vibrant and detailed prints. Expect bright, accurate colors and sharp lines, even photographic reproductions will look great on fabric.

The white ink base underneath is key to making designs pop. This is true even on black or very dark garments, so colors will remain bright. You avoid the muted look that can happen with some other printing methods and get a great dtf result every time.

Feels Great on Fabric

No one wants a design that feels like a thick, rigid plastic layer on their clothing. Ninja transfers usually have a soft texture, often described in the industry as a ‘soft hand’. The ink integrates with the fabric rather than sitting on the surface. This means the apparel is more comfortable. It also allows the design to move and stretch with the fabric. This is a big contributor to the professional look and feel of the final customized item.

Built to Last

Durability is important for any custom apparel. You want your designs to withstand multiple washes and daily wear without losing quality. Ninja transfers are known for their durability due to the special adhesive that bonds with fabric fibers.

When applied correctly, these dtf transfers can go through many wash cycles without cracking, peeling or fading. Following general garment care instructions will help extend the life of printed apparel. This durability means your custom items will look great for a long time.

Works on Almost Anything

The versatility of dtf transfers is another big benefit. Ninja transfers are not limited to just cotton t-shirts; they work great on a wide range of materials. This includes polyester, cotton-poly blends, spandex, nylon and for some transfer types even hard surfaces.

This means you can customize activewear, like items from Puma Golf or Dri Duck, or everyday apparel like Comfort Colors shirts and Thread fast Apparel. The applications extend to bags from Liberty Bags, hats from Big Accessories, jackets and many other items, especially when using quality blank apparel.

This flexibility is huge for businesses creating promotional items or individuals doing various creative projects. The dtf versatility means your creative possibilities are endless. These great dtf applications show how versatile the technology is.

Easy to Use

As mentioned before, ninja transfers are usually very user friendly. The transfers dtf come ready to press, so much of the intricate printing work is done beforehand. This makes the process much simpler for the end user.

Applying them with a heat press is generally a direct process. Most suppliers will provide guidelines for application time, temperature and pressure settings. This makes it easy for beginners to get great results quickly and with no steep learning curve.

Good for Small Batches and Complex Designs

Some printing methods are only economical for large volume orders or basic designs. Ninja transfers however are perfect for one off items or small production runs. This is because unlike screen printing, there’s no need to set up a screen for each color or design variation. Hey also handle complex, multi-color designs with ease, so you can have multiple designs on one order. You’re not limited in your color choices; the design on your computer will translate to the fabric perfectly. This gives you a lot of creative freedom and using a gang sheet will further optimize costs for multiple designs.

Using gang sheets, where multiple designs are printed on one sheet of film, is a great way to produce multiple custom dtf transfers at once. This is ideal for businesses that need various branding elements or individuals creating a collection of unique items. It maximizes the use of materials and printing time.

How to Apply a Ninja Transfer

Ready to try applying a ninja transfer? It’s often easier than you think. Below is a general step by step guide but always consult the instructions from your transfer supplier as settings may vary for different dtf transfers.

Preheat Your Heat Press

Turn on your heat press. Set it to the temperature recommended by your supplier for your specific ninja dtf transfer and fabric type, usually between 275-325°F (135-163°C). Let it heat up completely before moving to the next step.

Adjust Pressure

Make sure your heat press is set to medium to firm pressure. Not enough pressure will result in poor adhesion of the transfer. Too much pressure can damage delicate fabrics so find the sweet spot.

Pre-press Your Item

Place your garment or item flat on the bottom platen of the heat press. Press it for about 3-5 seconds. This will remove any residual moisture and smooth out wrinkles so the transfer has a smooth surface to adhere to.

Position the Transfer

Place the ninja transfer onto your item. The printed side (the side with the ink and adhesive) should be facing down, in contact with the fabric. You will be looking at the back of the carrier film; use heat resistant tape to secure it if working with slippery materials or precise placements.

Press the Design

Cover the transfer with a protective sheet, such as a Teflon sheet or parchment paper, to prevent direct contact with the heat platen. Close the heat press and apply pressure for the recommended time, usually 10-15 seconds.

Peel the Carrier Film This step is crucial. Some ninja dtf are hot peel, meaning you remove the film immediately after pressing while it’s still hot. Others are warm peel (remove after a few seconds of cooling), or cold peel (wait until the transfer is completely cool). Peeling at the wrong temperature can ruin your design so always follow your supplier’s peeling instructions carefully and peel smoothly.

Final Press (Optional but Recommended)

Many users do a quick final press for an additional 3-5 seconds after the carrier film has been removed. Cover the design with a protective sheet again for this step. This will enhance the durability and soften the feel of the transfer, embed it further into the fabric.

And that’s it. With some practice you’ll be applying ninja transfer designs like a pro. Remember, successful application is all about using quality custom dtf transfers, following the correct settings and peeling smoothly.

Where Can You Use Ninja Transfers? Get Inspired.

Now that you know what a ninja transfer is and how to apply it, where can you use these awesome designs? The applications are endless. Here are a few ideas to get you started and show you the versatility of dtf.

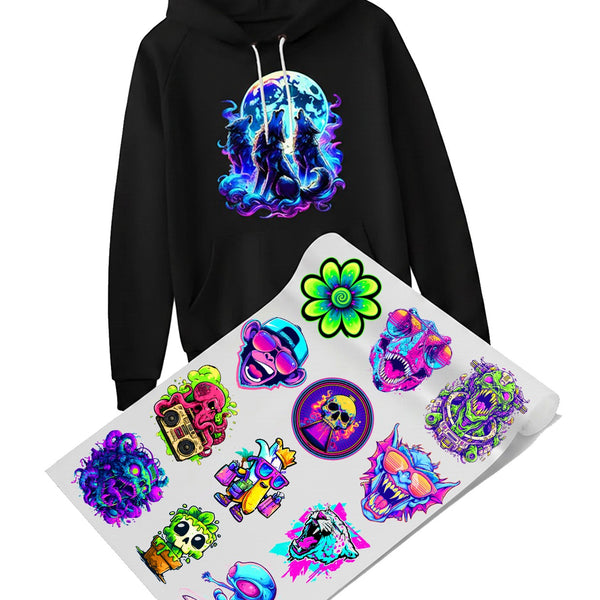

Custom Apparel

This is probably the most common and popular application. You can create custom t-shirts using fabrics like those from Authentic Pigment for a vintage look, or hoodies and tank tops for everyday wear. Consider designing team jerseys, band merchandise or unique fashion statements with detailed prints.

Since these dtf transfers work well on performance fabrics, they are great for customizing gym clothes, activewear or sports uniforms. Many people use them on blank apparel sourced for its quality and suitability for decoration. The ability to produce vibrant designs makes them perfect for spirited fan wear.

Personalized Accessories

Don’t limit your creativity to just clothing. Ninja transfers can also enhance accessories such as tote bags from Liberty Bags, backpacks and caps from Big Accessories. Imagine designing coordinated sets or adding a personal touch to everyday items you use or carry.

Canvas shoes also make for a fun and creative project for personalization. Small logos, intricate patterns or custom text can turn plain accessories into showstoppers. This makes ninja transfer a great tool for gift-giving or small batch production. Yes, you can also apply ninja transfers to home goods. Consider creating custom pillowcases, cushion covers for your living room or personalized aprons for the kitchen. Decorative tea towels or fabric wall hangings are other great ways to use these transfers.

This is a great opportunity to add unique accents to your living space or create personalized gifts for friends and family. The durability of transfers dtf means these items will remain beautiful over time. Customizing items for themed parties or seasonal decor also becomes much easier.

Promotional Products and Business Branding

For business owners, ninja transfer is a great way to produce branded merchandise. This can include staff uniforms, items for promotional giveaways or products for retail sale. The quality and durability of these custom dtf transfers reflects well on your brand image.

It’s an easy way to display your logo and branding on a wide range of items. Whether you’re a startup or an established company, using great dtf for branding is a smart move. The ability to produce detailed prints means your logo will look professional.

Essentially, if it’s made of fabric and can withstand the heat pressing process, it’s probably a candidate for customization with a ninja transfer. Check out DTF project ideas for more inspiration. This barely scratches the surface; your imagination is the only limit when using ninja dtf.

Finding a Great Ninja Transfer Source

How to Choose the Right DTF Transfer Supplier

Now you might be convinced about ninja transfer. But where can you get them and how do you choose a good supplier? This is important because the quality of the DTF transfer itself affects your final product.

Look for providers that specialize in DTF technology or high quality custom DTF transfers. Check customer reviews and testimonials to see how satisfied they are with print quality, durability and customer support. Positive feedback often highlights how these transfers stand out from others.

Check their production and shipping times, especially if you have deadlines. Some suppliers even offer free shipping which can be a big cost savings. Also review their pricing, some may offer discounts for bulk orders or for ordering DTF through specific programs where you can earn points.

Tips for a Smooth Ordering Experience

When choosing ninja transfers look for a supplier that provides clear, detailed application instructions. Helpful resources like video tutorials or guides on their website are a plus. Good customer support can prevent many issues especially for those new to using custom DTF products like ninja transfers DTF. Before you order your ninja DTF, don’t hesitate to contact potential suppliers with questions. Ask about their process for handling multiple designs, such as gang sheets which can be very cost effective. A good supplier of DTF transfers will be transparent and helpful.

A good source for your ninja transfer will make your customization projects easier and more successful. When choosing ninja especially for DTF transfers a good partner will give you professional results. Also check if their website has clear terms, privacy policy and accessibility statement as these often indicate a professional and customer focused business.

Troubleshooting Common Ninja Transfer Issues

Even with high quality transfers sometimes issues can arise during application. Knowing how to fix common problems with your ninja transfer can save a project. Here are some troubleshooting tips:

Transfer Not Sticking Properly

If your ninja dtf transfer design doesn’t stick properly start by checking your heat press temperature and pressure settings. These might be too low for the specific transfer or fabric. Make sure your press has reached the target temperature before application.

Some fabrics have manufacturer coatings that can prevent adhesion. Always pre-press the garment for a few seconds; this removes moisture and any potential residue creating a better surface for the dtf transfer. Inconsistent pressure across the platen can also be the culprit, check your press for evenness.

Design Cracking or Peeling After Washing

This problem usually means an issue during the initial heat press application. Potential causes are insufficient pressure, incorrect temperature or not enough press time for the dtf transfers. Make sure you’re following the supplier’s application instructions for your specific product.

It’s also important to wait the recommended 24-48 hours before washing a newly pressed item. Washing too soon can compromise the adhesive bond before it fully cures. A post-press (a second, brief press after peeling the carrier film) can greatly improve washability and prevent losing quality over time.

Colors Look Dull or Off

If the colors of your applied ninja transfer look less vibrant than expected this could be due to the quality of the transfer itself. Or it might be related to your heat press settings; too much heat or too long pressing time can sometimes change ink colors. Make sure your original artwork file was high resolution and in the correct color mode (CMYK is often preferred for print) before submitting it for printing great dtf designs. Before you order your ninja DTF, don’t hesitate to contact potential suppliers with questions. A good supplier will use premium inks and films for bright and accurate colors and provide clear guidelines to help you avoid issues and get the best results for your designs.

Film Won’t Peel

Difficulty peeling the film usually means you’re peeling at the wrong temperature. Double check if your ninja dtf transfers are hot peel, warm peel or cold peel. Peeling a cold peel transfer too soon or waiting too long to peel a hot peel transfer can cause application issues.

Peel the film smoothly and consistently, don’t yank it. If the issue persists, re-check the supplier’s instructions as peeling technique is crucial for these dtf transfers. Sometimes a slight adjustment in waiting time makes all the difference.

These are a few common issues you may encounter with ninja transfer. Most problems with these dtf transfers can be fixed by making small adjustments to your application process. Don’t be discouraged if your first attempts aren’t perfect; practice makes perfect.

Conclusion

In summary, the ninja transfer, with DTF technology, is a great way to create custom items. It has great print quality, soft feel on fabric and durability. And it’s easy to use on various fabrics and materials.

Whether you’re a hobbyist, small business owner with multiple designs or just someone who loves custom gear, the ninja transfer method is recommended. Try this custom dtf transfers and you’ll see a huge difference in your creative projects. You’ll be able to produce amazing and professional looking custom products with confidence.

Remember, choosing ninja transfers means choosing a modern, efficient and versatile decoration method. From single custom pieces to larger batches with gang sheets, the possibilities are endless. This technology is making high quality customization more accessible to everyone and ninja transfers dtf are at the forefront of this movement.