You've heard whispers about them. Maybe you've seen their striking colors and felt their smooth finish. What exactly are these effective ninja prints? They are significantly changing how folks think about custom designs on clothes and gear. You'll learn all about high-quality ninja prints and why they might be perfect for your next project.

So, What Are Ninja Prints Anyway?

You might be picturing stealthy figures when you hear "ninja prints." That's not far off in terms of skill and impact. These prints are known for their sharp details. They also have bright, vivid colors that last a long time, often utilizing an expanded color gamut for superior reproduction. Think of them as high-quality transfers that bring your designs to life with power.

These prints are often a type of Direct to Film (DTF) transfer, a technology revolutionizing the custom dtf transfers market. This method allows artists to print designs onto a special film using specialized dtf transfer printers. Then, this film is heat-pressed onto fabric, creating durable and vibrant graphics. The "ninja" part refers to how effective they look and perform, much like a skilled ninja delivering a precise strike.

They are agile enough for many fabrics and fight off fading very well. Why do they stand out so much from other printing methods? Ninja prints, or more specifically ninja transfers, combine brightness with softness, delivering top-tier print quality. They don't feel thick or stiff on a shirt, making them a great pick for comfortable, everyday clothing including popular brands like Comfort Colors.

Plus, they can handle very detailed designs; even small text or tiny elements look crisp. This makes ninja transfers dtf a go-to for intricate artwork. Many providers also offer free samples or design consultations.

The Secret Moves: How Ninja Prints Come to Life

Creating ninja prints involves an innovative, modern process. It sounds complex, but it's quite ingenious. It lets printers make high-quality transfers without a lot of the old fuss associated with methods like screen printing. Here's a peek behind the curtain at how these transfers dtf are made.

Step 1: Your Creative Design

It all starts with your digital artwork, which you will typically upload artwork to the provider's system. This could be a logo, a detailed illustration, or even multiple designs arranged on a gang sheet. The better the art, the better the final print, so high-resolution files (like PNGs with transparent backgrounds) are recommended for the best results. Many services provide design tools to help prepare the file perfectly, ensuring elements like color correctness are spot on.

Consider using vector files for scalability without loss of quality. If you are creating custom dtf graphics, pay attention to line thickness and negative space. This initial step is crucial for achieving the desired quality printing outcome.

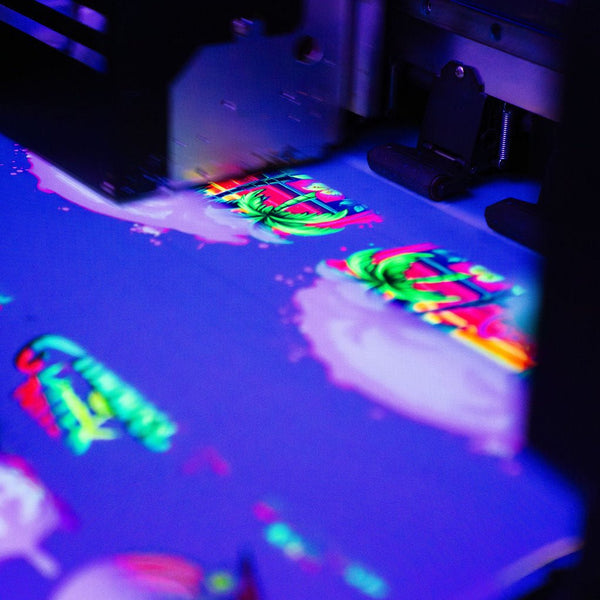

Step 2: Printing on Special Film

Next, the design is printed onto a clear PET film using a specialized dtf transfers printer. This isn't just any film; it's made for this job, often referred to as a transfer film. Special DTF printers use eco-friendly water-based inks, chosen for their ability to produce bright colors. They print the colors first, and then they usually print a white layer on top. This white layer makes colors pop, especially on dark clothes, and is a hallmark of highest quality prints.

Step 3: The Magic Powder

A special thermoplastic adhesive powder is key to making ninja dtf transfers stick. While the ink is still wet on the film, it's coated with this fine powder. The powder sticks only to the inked areas. Any extra powder is shaken off carefully, often automatically in more advanced setups. This part is vital for a strong, durable bond once heat pressed.

Step 4: Curing the Transfer

The film with the ink and powder then goes through a curing process. It's gently heated in a curing oven or under a heat press at a lower temperature. This melts the adhesive powder and bonds it with the ink to create a ready-to-press transfer. The transfer is now stable and can be stored for months or used right away, contributing to fast turnaround times for custom orders.

A benefit for you is that you don't need heavy gear for application, just a reliable heat press. You just get the finished ninja prints, often on gang sheets if you ordered multiple designs. Then you can apply them with a simple heat pressing process. This makes them great for small businesses or hobbyists. You can find more about heat pressing techniques on sites that explain garment decoration.

Unmasking the Power of True Ninja Prints: The Big Wins

Why are so many people choosing ninja prints? The benefits are clear and very appealing. They solve a lot of problems found with older printing methods. Let's look at what makes these custom prints so good.

Colors That Pop Like Crazy

One of the first things you'll notice is the color; ninja prints boast exceptionally vibrant colors. The colors are rich and full, looking stunning on both light and dark fabrics. This is because of that white ink base mentioned earlier. It acts like a bright canvas for the colors, making them really shine, delivering those sought-after bright colors that catch the eye.

Built to Last: Prints That Fight Fading

These prints are very durable. They can handle a lot of washes without fading or cracking, often outlasting the garment itself. Good quality ninja prints feel like part of the fabric, not just sitting on top. This means your creative designs will look great for a long, long time, perfect for items like long sleeve shirts or polo shirts that see frequent use.

Stick Them Anywhere: Amazing Fabric Friends

Versatility is a significant advantage for ninja prints and the versatility dtf transfers offer. They work great on so many different materials. Cotton, polyester, blends, spandex, and even treated fabrics are no problem. They even stick to tricky stuff like leather or nylon sometimes, expanding options beyond typical short sleeve tees to items like quarter zip jackets or tank tops.

Moves With You: Super Stretchy, No Cracks

Nobody likes a print that cracks when you stretch it. Ninja prints have excellent stretchability. This makes them well-suited for sportswear or active clothing. The print flexes with the fabric, keeping it looking smooth and whole. It's a big step up from some stiffer options out there.

Every Tiny Detail Counts

Got a design with fine lines or small text? Ninja prints can handle it with precision. The process allows for incredible detail. Intricate details come out sharp and clear. This is something that can be hard for other methods, like vinyl cutting, to match. Your designs can be as complex as you want, making them ideal for sophisticated branding or elaborate artwork.

Feels Good on Your Shirt

How a print feels is very important. Nobody wants a thick, plasticky logo on their chest. Ninja prints offer a soft feel, often described as having a "soft hand." They are lightweight and breathable. After the first wash, they often feel even softer, enhancing the comfort of apparel from brands like Threadfast Apparel or Puma Golf.

Ninja Prints Throwdown: How They Stack Up

It's helpful to see how ninja prints compare to other ways of decorating clothes. Each method has its place. But ninja prints (as high-quality DTF) offer an attractive mix of features. Let's see how they do against some common rivals.

Ninja Prints vs. Screen Printing

Screen printing has been around for ages, known for its durability. It's effective for large runs of simple designs. But setup can be costly and time-consuming, with each color needing its own screen, making screen printing less economical for small, colorful orders. So, lots of colors mean lots of setup.

Ninja prints, however, can do full color easily, a key feature of the dtf transfer process. There's no extra setup per color. This makes them suitable for smaller orders or designs with many shades. Screen prints can feel a bit thick sometimes, especially with many colors, whereas ninja prints usually have a softer touch. For overall print longevity, quality DTF aims to match traditional screen printing durability.

Ninja Prints vs. Direct-to-Garment (DTG)

DTG printing shoots ink right onto the fabric, like an inkjet printer. It's good for complex, full-color designs on cotton. But DTG often needs pre-treatment, especially for dark shirts. This adds a step and can affect the feel slightly.

Ninja prints don't need garment pre-treatment because the design is made on film first. This means they work great on dark polyester, which DTG can struggle with. Also, some find ninja dtf colors to be even brighter on more fabric types than DTG, providing excellent vibrant colors across a wider range of materials.

Ninja Prints vs. Heat Transfer Vinyl (HTV)

HTV involves cutting designs from colored vinyl, then pressing them onto the shirt. It's popular for simple names and numbers. But detailed designs are tough, and you have to weed out all the extra vinyl, which takes time. Layering multiple colors can also be tricky and bulky.

Ninja prints have no weeding; what you print is what you press. Complex, multi-color designs are simple to produce with transfers dtf transfers. They are usually much softer and more breathable than layered vinyl, making them much more comfortable to wear. This advantage makes ninja prints dtf a superior choice for intricate, full-color graphics on apparel.

|

Feature |

Ninja Prints (DTF) |

Screen Printing |

DTG |

HTV |

|

Color Complexity |

Excellent (Full color, no extra setup) |

Good (Each color needs a screen) |

Excellent (Full color) |

Limited (Layering needed for multi-color) |

|

Fabric Versatility |

Excellent (Cotton, poly, blends, more) |

Good (Varies by ink) |

Limited (Best on cotton, pre-treat needed) |

Good (Specific vinyl for specific fabrics) |

|

Feel on Garment |

Soft, lightweight |

Can be thicker, especially with more colors |

Soft, part of fabric |

Can be thick, especially layered |

|

Durability |

Excellent |

Excellent |

Good (can vary by pre-treat and fabric) |

Good (can vary by vinyl type) |

|

Small Orders |

Very cost-effective |

Can be expensive due to setup |

Cost-effective |

Cost-effective |

|

Detail Level |

Excellent (Fine lines, small text) |

Good (Depends on screen mesh) |

Very Good |

Limited by cutting/weeding |

Be the Design Master: Creative Ideas for Your Ninja Prints

Now that you know what ninja prints can do, what will you create? The possibilities are almost endless with custom dtf transfers. Here are a few ideas to get your imagination fired up, perfect for personal projects or growing a business that might feature products from brands like Dri Duck or Big Accessories.

Rock Your Own Style: Custom Clothes

This is the most popular use for ordering custom prints. Think about making t-shirts for your band using blank t-shirts or sourcing other blank apparel. Or maybe hoodies for your club or group. You can create one-of-a-kind pieces that show off your personality, perhaps using garments from featured brands in a supplier's product catalog. Custom hats with sharp logos look great too. Ninja prints make it easy to wear your art.

Cool Gear: Bags, Totes, and More

Don't stop at just shirts; the versatility dtf allows for much more. Ninja prints work great on accessories too, like those from Liberty Bags. You can brand tote bags for an event or create personalized gym bags or aprons. Even hard goods like phone cases or mugs (if suitable for the transfer type) can be decorated, alongside traditional sticker printing for complementary branding. This is a fun way to make useful items special.

Some advanced DTF applications even extend to items like canvas gallery wraps or other fine art reproductions, although this is a more specialized area. You might also find services like Poster Ninja or Print Ninja that offer various types of custom printing including posters poster prints.

Small Business Superpower

For small businesses, ninja prints are a valuable tool, especially when ordering dtf. You can easily create branded merchandise. Sell shirts with your company logo or make uniforms for your team. There's no need for huge investments in inventory because you can order prints as you need them, often with a quick business day turnaround for processing before shipping. This makes testing new designs fast and low-risk.

Many apparel decorators explain how such prints benefit small businesses on their platforms. Look for suppliers who offer fast turnaround times, possibly free shipping on bulk orders, and even loyalty programs where you can earn points. Easy order tracking is also a must.

Keep Your Prints Mighty: Care Tips

You want your high-quality ninja prints to last. Fortunately, taking care of them is easy. With a few simple steps, your designs will stay vibrant and resist cracking wash after wash. This preserves the quality of your ninja transfers dtf applications.

First, turn your garment inside out before washing. This protects the print from rubbing against other clothes and shields it from harsh zipper and button action. Use cold or lukewarm water for washing. Hot water can be tough on prints and fabrics over time.

Regarding detergent, a mild one is best. Avoid using bleach or strong stain removers directly on the print. These can sometimes damage the colors or the print itself. Gentle cycles are also kinder to your decorated apparel.

Drying needs a bit of care too. It's best to hang dry your items. If you must use a dryer, choose a low heat setting. High heat is a print's enemy; it can cause fading or even damage the adhesive. Also, never iron directly on the ninja print. If you need to iron the garment, iron it inside out or place a cloth over the print area.

By following these tips, your ninja prints will keep looking great. You'll enjoy your custom items for many wears to come. Proper care makes all the difference in maintaining the highest quality appearance.

Finding Your Quality Ninja Prints Connection

Ready to try ninja prints for your next idea? Finding a good supplier is important. You want prints that live up to the "ninja" name. Look for quality materials and vibrant results; this contributes to you getting the best performance from your transfers dtf.

Ask about the inks and films they use; high-quality components lead to better prints. Don't be afraid to ask for samples from providers like Print Ninja. Seeing and feeling a sample print can tell you a lot about its stretch, feel, and color brightness. This can help you judge if it's right for you and their typical turnaround times.

Read reviews or testimonials from other customers, as this can give you an idea of their service and print quality. Good communication from the printer is also a plus; they should be able to answer your questions clearly. Check their website for a clear privacy policy and accessibility statement. Also, inquire about their wait time, sometimes referred to as the ninja wait time or just ninja wait, which is the production queue before shipping, often quoted in business days.

The online cart cart system for placing orders should be user-friendly. Many local print shops are now offering services like DTF printing near you, making it easier to connect and discuss projects. A reliable partner will help you achieve great results every time you use ninja dtf transfers.

Pay attention to details like privacy policy terms and how they handle your artwork and data. A transparent supplier will clearly state all rights reserved concerning their platform and services. This helps build trust for long-term partnerships.

Conclusion

So there you have it. Ninja prints offer an excellent way to get brilliant, long-lasting designs on all sorts of items. They combine vibrant colors, amazing detail, and a soft touch, often surpassing other methods in overall appeal. Plus, they work on a wide range of fabrics, from basic blank t-shirts to specialized performance wear.

Whether you're making custom tees for fun or branding for your business, these ninja prints are a strong choice. The versatility dtf transfers bring to the table is hard to beat. Now, you should feel ready to explore what these effective prints can do for you and your creative or business projects. Consider using ninja transfers for your next apparel customization needs.