You've probably heard the term "DTF printing" buzzing around. Maybe you're in the custom apparel game, or perhaps you're just curious. Understanding the whole meaning of DTF printing is essential if you're looking to create vibrant, lasting designs on fabrics, making it a crucial piece of knowledge for anyone in the custom printing sphere. It's a method that has significantly changed how people perceive custom prints and has opened up new avenues for printing businesses. This article breaks down the DTF printing meaning, making it clear and simple for everyone looking to grasp this innovative printing technology.

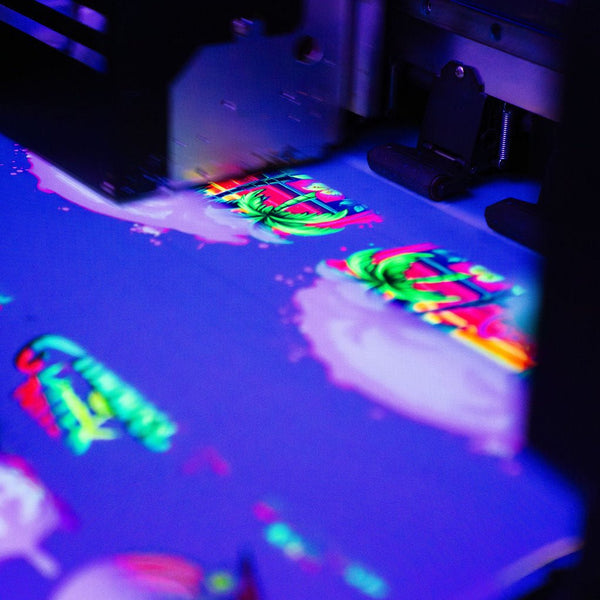

So, what's the big deal about DTF and its impact on the printing industry? It's a printing technique that's gaining a lot of attention, and for good reasons, particularly for its versatility and the quality prints it produces. You'll see how it offers incredible flexibility and quality for a wide range of applications, including cotton and other materials. We will cover everything, from the DTF printing process itself to the necessary equipment, including a dedicated DTF printer and heat press machine.

So, What Exactly is DTF Printing?

DTF stands for Direct-to-Film, which succinctly describes its core mechanism. This isn't like printing directly onto a t-shirt, a common misconception. Instead, your intricate colour design is first printed onto a special kind of film, specifically PET film, using a specialised inkjet printer and DTF ink. Then, this printed film, now a DTF transfer, is transferred to the fabric using heat and pressure from a heat press.

Think of it like a high-tech, super durable decal, but with a much better hand feel than many traditional transfers. The magic happens with special DTf inks, including a crucial white ink layer, and an adhesive powder, often a hot melt adhesive powder. This combination creates DTF prints that are bright and feel great on various materials, making the meaning of DTF printing synonymous with quality and adaptability.

One significant advantage is that DTF works on a wide range of fabrics, distinguishing it from other printing methods. We're talking cotton fabrics, polyester, blends, leather, and even nylon, making it suitable for everything from a custom t-shirt to more specialised apparel. This versatility across a wide range of substrates is a primary reason why many in the printing business are turning to DTF for their production needs.

The DTF Printing Process: A Step-by-Step Look

Converting a digital design into a printed shirt involves several key steps in the DTF printing process. Each one is important for the final print quality of the DTF transfers. Let's walk through the process of how this innovative film printing works, from initial design to the finished garment.

Step 1: Designing Your Artwork

Everything starts with your digital design, which will ultimately become the DTF print. You need a good-quality digital file for your desired surface. This is because the print quality will only be as good as the image you provide; high-resolution artwork is crucial for achieving sharp, clear results.

Most designers use software like Adobe Photoshop or Illustrator to prepare their artwork, ensuring the colour design is vibrant and accurate. You'll want to pay attention to the resolution, making sure it's high enough (typically 300 DPI) for a crisp film print. Using a CMYK colour profile is common, although some RIP software can effectively manage RGB files for the DTF printer.

Step 2: Printing on the PET Film

Once your design is ready, it's time for the actual printing process onto the transfer film. This isn't done on regular paper but on a special transparent material called PET (Polyethene Terephthalate) film, also known as DTF film. These films are specifically treated to accept the DTf inks correctly and ensure a clean release after heat transfer.

The DTf printers used are often modified inkjet printers or purpose-built machines designed for this specific printing method. They use specialised DTf inks, which typically come in CMYK (Cyan, Magenta, Yellow, Black) plus White. First, the colours of your design are printed on the PET film; then, a white layer of white ink is printed on top. This white ink underbase is crucial as it makes the design opaque and allows the colours to pop, especially on dark or colored fabrics.

Step 3: Applying the Adhesive Powder

With the ink still wet on the DTF film, the next step is to apply an adhesive powder. This powder is typically a fine Thermoplastic Polyurethane (TPU), also known as melt adhesive powder or hot melt adhesive. It looks like fine white sugar and is essential for bonding the print to the garment.

The powder is sprinkled generously over the wet ink on the film print. The ink adheres to the powder, and any excess powder is then shaken off, leaving a fine, even layer of melt adhesive that sticks only to the printed areas. Some setups feature automated shakers and powder applicators, streamlining this part of the DTF printing process, particularly for higher production volumes.

Step 4: Curing the Film

Now, the PET film, along with its ink and adhesive powder coating, needs to be cured. This critical step involves heating the film to melt the TPU powder, transforming it into a smooth adhesive layer. This process also helps to further dry the DTF ink, preparing the DTF transfer for application.

Curing can be done in a few ways, such as using a heat press by hovering it just above the film without direct contact. Others use small curing ovens or even specialised tunnel dryers for higher volume, which can significantly improve production time. The right temperature and time are critical, typically around 300-350°F (150-175°C) for a couple of minutes. However, always follow the supplier's guidelines for the specific hot melt adhesive powder being used.

Step 5: Transferring to the Garment

Your DTF transfer is now ready to meet the fabric, the desired surface for your design. This is where the heat press machine comes into full play for the heat transfer. You position the cured film onto the garment, such as a short-sleeved or long-sleeved comfort-coloured t-shirt, exactly where you want the design.

A quality heat press applies both heat and pressure evenly across the transfer film. Typical settings for this printing method might be around 300-325°F (150-160°C) for 10-15 seconds. These settings can vary depending on the fabric type (including cotton or synthetics) and the specific dtf supplies used, so testing is always recommended for optimal print quality.

Step 6: Peeling the Film

After pressing, the design has transferred to the fabric, and the DTF ink is bonded with the melted adhesive. The final step in the DTF printing process is to peel off the PET film. Some dtf films are "cold peel," meaning you let them cool down completely before peeling, while others are "hot peel" or "warm peel," which can affect overall production time.

Peeling reveals your vibrant, transferred design – the dtf print now adhered to the garment. It's often a very satisfying moment to see the quality print. Sometimes, a quick post-press for a few seconds with a protective sheet can further enhance the hand feel and durability, resulting in a more matte finish and improved absorption into the fabric fibres for excellent wash results.

Why Choose DTF? Understanding the Advantages

So, why is everyone discussing DTF and its increasing role in the printing industry? Several solid benefits make it an attractive option for many printing needs, especially for a printing business seeking versatility. It comes down to flexibility, the quality of the DTF prints, and efficiency.

Versatility with Fabrics

One of the most significant advantages of DTF printing is its ability to print on almost any surface. Cotton, polyester, rayon, nylon, silk, leather, and various blends, including cotton fabrics of all types, are all fair game. This opens up a vast range of product possibilities beyond just a standard t-shirt print, extending to hoodies, bags, and more specialised items.

Unlike methods like DTG printing (Direct-to-Garment), which works best on cotton, or sublimation printing, which requires polyester, DTF effectively bridges the gap. This makes it highly convenient for shops that want to offer a wide variety of custom items without needing multiple types of printing setups, thereby handling diverse demands for custom printing.

Vibrant Colours and Detail

DTF prints are renowned for their brightness and sharpness, two key elements of their high-quality print characteristics. The white ink underbase, or white layer, is pivotal for this. It makes colours stand out vividly, even on the darkest fabrics, allowing for truly impactful colour design outcomes.

Complex designs with fine lines, small text, and gradients also reproduce exceptionally well with DTF technology. This means your creative possibilities are wide open for digital printing. Photorealistic images and intricate logos look great with DTf prints, delivering results that often surpass expectations.

Durability and Washability

A good print needs to last, and DTf transfers are quite durable when applied correctly. They can withstand many wash cycles and exhibit excellent wash performance without cracking, peeling, or fading significantly. The print has a slightly stretchy quality and a soft hand feel, which helps it move with the fabric and maintain comfort.

Of course, proper garment care helps extend the life of any print, ensuring it continues to exhibit excellent longevity. Washing inside out in cold water and air-drying or tumble-drying on a low setting are good practices for these high-quality prints. Many people find DTF prints hold up as well as, or even better than, other digital printing methods or even some types of transfer vinyl.

No Pre-Treatment for Most Fabrics

With DTG printing, especially on dark garments, a pre-treatment liquid needs to be applied to the fabric to help the ink bond properly. DTF, however, doesn't require this pre-treatment step for most materials, which is a significant advantage in the printing process. This is a clear benefit of the DTF printing, meaning faster turnaround.

Skipping pre-treatment saves time, money, and an extra chemical process in the production workflow. This simplifies and streamlines the workflow, resulting in a reduction of overall production time. It is one of the reasons people find DTF efficient and a preferred printing method for custom apparel.

Cost-Effectiveness for Small to Medium Runs

For small custom orders or medium-sized batches, DTF can be a very cost-effective option, a boon for any printing business. Unlike screen printing, which has significant setup costs for each colour and is better suited for large volumes, DTF allows for full-colour prints with practically no minimum order quantity. This is great for personalised items, such as custom t-shirts, or businesses operating on a print-on-demand model.

While individual DTG transfers might cost more in materials than a mass-produced screen-printed item, the lack of extensive setup makes them accessible for smaller quantities. You print what you need, when you need it, optimising resources and reducing waste associated with outdated printing methods.

Understanding the DTF Printing Meaning in a Practical Sense

Beyond the technical details, what does the DTF printing mean for businesses and creators? It signifies new opportunities and the democratisation of custom apparel creation. It's about making high-quality custom printing more accessible to a broader audience.

The term "dtf meaning in printing" broadly refers to this innovative direct-to-film technology. Specifically, "dtf printer meaning" refers to the specialised inkjet printer used in the process, while "dtf print meaning" or "dtf prints meaning" relates to the actual finished designs on garments. When people ask about "DTF transfers meaning," they're inquiring about the printed PET film with adhesive, which is ready for application.

For apparel, phrases like "dtf meaning shirts" or "dtf clothing meaning" highlight its common application in decorating t-shirts, hoodies, and other clothing items. Some even encounter the term "dtf sticker meaning," which typically refers to UV DTF, a variation used for creating durable stickers for hard surfaces. Understanding these nuances, like the difference between DTF and "dtf meaning screen printing" (where DTF offers more versatility for small, colourful runs), helps clarify its place in the printing industry.

Many types of businesses are adopting DTF technology. Small t-shirt print shops, online custom apparel stores, and even established promotional product companies find it useful. Designers and artists can easily bring their creations to life on various products, from short-sleeved tees to long-sleeved jackets, including popular Comfort Colours blanks chosen for their dye characteristics and feel.

You'll see DTF used for t-shirts, hoodies, activewear, hats, bags, and even items like aprons or bandanas. Basically, if you can lay it flat in a heat press machine and it's the desired surface for decoration, you can probably put a DTF transfer on it. This opens many doors for creative product offerings and expands the reach of digital printing.

In the larger picture of garment decoration, DTF fills an important gap. It combines some of the best qualities of other printing methods. It offers the colour vibrancy often associated with high-end DTG printing and fabric versatility that can exceed some heat transfer vinyl options, but with a generally softer hand feel and better detail for complex colour designs.

DTF vs. Other Printing Methods: A Quick Comparison

To truly understand where DTF fits, it is helpful to compare it with other popular fabric printing techniques, such as screen printing, DTG, and sublimation printing. Each printing method has its strengths, and the best choice depends on your specific needs, including factors like volume, fabric type, and desired print quality. This comparison will also touch upon transfer vinyl and white toner systems as alternatives.

Here's a quick rundown of how DTF compares to DTG (Direct-to-Garment), Screen Printing, and Sublimation Printing. This should clarify its position in the competitive landscape of printing technologies.

|

Feature |

DTF Printing |

DTG Printing |

Screen Printing |

Sublimation Printing |

|

Fabric Compatibility |

Wide (cotton, poly, blends, leather, nylon). Works well on a wide range of materials. |

Primarily cotton; pre-treatment for darks. Less versatile for synthetics. |

Versatile, ink types vary per fabric. Can print on many surfaces. |

Polyester or poly-coated items only. Does not work on cotton. |

|

Color Vibrancy |

Excellent, with white ink underbase ensuring colors pop on all fabric shades. |

Good for light fabrics; white ink is needed for darks. |

Good, needs multiple screens for many colors, increasing setup. |

Excellent, photographic, dye becomes part of fibers. |

|

Print Feel (Hand Feel) |

Soft, slightly raised, flexible layer. Generally good hand feel. |

Very soft; ink dyes the fibres directly, resulting in minimal hand feel. |

Can be thick, especially with many colours or plastisol inks. |

No feel, dye becomes part of the fibres, resulting in a completely smooth finish. |

|

Durability & Washability |

Good to Excellent. Prints exhibit excellent wash resistance. |

Good, with proper pre-treatment and cure. It can fade over time. |

Excellent, very robust and long-lasting. Industry standard for durability. |

Excellent, permanent, as dye is molecularly bonded to fabric. |

|

Small Run Cost |

Moderate. No screen setup. Efficient for one-offs and small orders. |

Highish due to ink and pre-treatment per item. Good for samples. |

Very High due to the extensive screen setup for each colour. |

Moderate to High, depending on the printer and ink costs for specialised systems. |

|

Large Run Cost |

Moderate. Slower per piece than screen printing. |

Moderate. Slower per piece. |

Low. Very efficient for bulk orders once set up. |

Moderate. Can be efficient but is limited by item type. |

|

Detail Capability |

Very Good, fine lines and intricate colour designs are possible. |

Good, can lose very fine detail, especially on textured fabrics. |

Okay, depends on screen mesh count; fine detail can be challenging. |

Excellent, photographic detail, smooth gradients. |

|

White Ink Usage |

Yes, essential for dark or coloured fabrics via the white layer. |

Yes, for dark or coloured fabrics, it adds to the cost and maintenance. |

Usually, a separate screen and a pass add to the setup and cost. |

Not applicable, as sublimation dyes are transparent and require light-coloured fabric. |

This table shows that DTF printing is a strong contender in many areas, offering a balanced solution. It is especially strong for versatility and vibrant prints on varied materials. Compared to transfer vinyl, DTF often provides a softer hand feel and better detail for complex graphics. However, high-quality vinyl still has its place in certain applications, such as bold, single-colour designs or speciality finishes. Some operations also consider white toner laser printers for transfers, which offer no-weed capabilities similar to DTF but involve a different printing technology and often a different feel and durability profile.

What You Need to Start with DTF Printing

Thinking about jumping into DTF for your printing business or creative projects? You'll need specific equipment and supplies. Getting set up properly with the right DTF printer and accessories is crucial for achieving consistent, high-quality results and efficient production times.

First, the DTF printer itself is key. These are typically specialised inkjet printers, sometimes modified from existing Epson or similar models, or purpose-built DTF printers designed to handle DTF inks and the DTF film. Look for printers with reliable print heads, good support, and features suitable for your intended volume. They range from smaller desktop units for entry-level users to larger, industrial machines for high-volume custom printing.

You'll need high-quality PET films, also known as DTF film or transfer film, which come in rolls or sheets and can be either hot peel or cold peel. Also, specialized DTF inks are a must; these are pigment inks formulated for this process, including CMYK and essential white ink. Don't forget the TPU adhesive powder (melt adhesive powder or hot melt powder), which comes in different grades that affect melt characteristics, final hand feel, and the durability of the DTF prints.

For curing the powder on the film print, a consistent heat source is required. This could be a simple heat gun for very small-scale work, a heat press machine used in hover mode, or a dedicated curing oven or tunnel dryer for more professional and higher-volume work. Then, you'll need a good-quality heat press (press machine) for transferring the design to the garment. This press should provide consistent temperature and even pressure for successful heat transfer.

Software is another important piece for managing the DTF printing process. RIP (Raster Image Processor) software helps manage colours accurately, print the white layer correctly behind the colour design, and control ink flow for optimal print quality and cost. Popular options like AcroRIP or CADlink Digital Factory are often used with a DTF printer. And, of course, you'll need a computer with design software, such as Adobe Creative Suite or CorelDRAW, to create and prepare your artwork.

Potential Challenges and How to Address Them

While DTF printing offers many benefits, it's not without its learning curve, especially for newcomers to this printing technology. New users often face a few common challenges. Being aware of them can help you troubleshoot and maintain consistent print quality and efficient production times.

A period of trial and error is involved in mastering the DTF printing process. Getting the settings just right for temperature, pressure, and timing on the heat press machine requires practice with your specific DTF printer, inks, film, and adhesive powder. Each part of the process interacts with the others, and what works for one fabric, such as cotton, might need tweaking for another or a different desired surface.

Printer maintenance is crucial, especially for DTF printers that use white ink. The print heads, especially those jetting the dense white DTf ink, can be prone to clogging if not maintained meticulously. Regular cleaning routines, daily Chaka-Chakas (head cleans), and proper environmental controls (humidity and temperature) are vital. Many users find helpful tips on maintenance in resources such as technical support communities, supplier documentation, or specialised printer manuals.

Achieving consistent adhesive powder application can sometimes be tricky with the hot melt adhesive powder. Using too little powder, the DTF transfer may not stick well or may fail during washing. Too much or uneven application of the melt adhesive can lead to a messy print, affect the hand feel, or cause issues with powder sticking where it shouldn't. Humidity and static electricity can also play a role in this process, so managing your print environment is beneficial.

Lastly, curing the adhesive powder requires heat, and this process can release some fumes from the hot melt adhesive. Proper ventilation in your workspace is important for safety and comfort. Always follow safety guidelines provided by equipment and material suppliers to ensure a safe operating environment for your printing business.

The Future of DTF Printing

DTF printing technology is relatively new compared to older methods, such as screen printing. But it is growing fast within the printing industry. It appears poised to become a major player in the custom apparel, t-shirt printing, and textile decoration industries worldwide, thanks to its flexibility and the high-quality prints it produces.

We are already seeing advancements in this digital printing field. DTF printers are getting faster, more reliable, and more automated. Inks and DTF films are continually improving, offering even better washability, a softer hand feel, and enhanced stretchability, which allows prints to exhibit excellent durability. Automation is also increasing, with all-in-one systems that print, powder, cure the DTF film, and sometimes even cut the transfers continuously, reducing manual labour and production time.

The ease of DTF also fits perfectly with the rise of e-commerce and print-on-demand business models, enabling businesses to offer a wide range of custom t-shirt options, including short-sleeved and long-sleeved garments. Small businesses and individual creators can produce high-quality custom goods without massive investment or inventory, thanks to this accessible printing technology. There is also a growing niche for UV DTF, which creates durable, adhesive-backed "stickers" or transfers for hard, non-fabric surfaces, expanding the DTF sticker meaning into new markets.

There's also a growing focus on sustainability within the printing industry. DTF uses water-based DTF inks, which is a plus. Some research is looking into more eco-friendly DTF film options and bio-based or recyclable hot melt adhesive powders, as well as powder recycling systems to minimise waste. These developments will make DTF an even more attractive option for custom printing, aligning with consumer demand for greener production methods.

Conclusion

Direct-to-Film printing is a powerful and versatile printing method for decorating garments and other textiles, effectively broadening the meaning of DTF clothing. Its ability to produce vibrant, detailed, and durable DTF prints on a wide array of fabrics, including cotton, sets it apart from many other printing methods. Understanding the complete meaning of DTF printing involves knowing the intricate DTF printing process, its significant benefits for a printing business, the necessary equipment, such as a DTF printer and heat press, and how it compares to techniques like screen printing or sublimation printing.

For anyone involved in custom apparel, promotional items, or creative design, understanding the meaning of DTG printing unlocks exciting possibilities for producing quality prints. It simplifies high-quality, full-colour printing, especially for smaller runs and detailed colour designs, making it easier to create a custom t-shirt or any other personalised item. This printing technology is making a significant impact on the printing industry. It is likely to continue shaping the future of custom printing, offering an excellent balance of quality, versatility, and cost-effectiveness for various applications.