DTF vinyl is rapidly changing the custom apparel scene. This innovative heat transfer method lets you create vibrant, durable designs on almost any fabric. Whether you're an experienced professional or just beginning, DTF (direct-to-film) printing presents many possibilities for your creative projects.

So what is this dtf vinyl exactly, and why is its popularity surging? Let's explore everything you need to understand about this transformative technology. It's more than just another transfer vinyl; it's a new approach to customization.

What is DTF Vinyl?

Interestingly, dtf vinyl is not vinyl in the traditional sense. It's a specific type of transfer film, often referred to as dtf film, used in the dtf printing process. The method employs a special powder adhesive and a heat press to bond designs securely onto various fabrics.

Unlike conventional heat transfer vinyl (HTV) or adhesive vinyl methods, DTF allows for full-color, photorealistic prints with impressive detail. The resulting transfers are soft to the touch, stretchable with the fabric, and very durable. A major advantage is that DTF works effectively on cotton, polyester, blends, and even challenging materials like nylon or dark vinyl substrates.

The final dtf print often feels lighter and more integrated into the fabric than many older heat transfer technologies. This makes it a preferred choice for fashion and performance apparel. Many print shop businesses are adding dtf vinyl printing to their services.

How DTF Printing Works

The dtf printing process involves several important steps to achieve high-quality dtf transfers:

- Design Creation: Your artwork is prepared digitally. This typically involves using graphic design software like Adobe Illustrator or CorelDRAW to create or refine the image. Vector art is often preferred for scalability, but high-resolution raster images can also be used.

- Printing: A specialized DTF printer, equipped with dtf ink (including a white ink layer), deposits the ink onto a transparent PET dtf film. The printer first lays down the colors (CMYK) and then typically prints a white ink layer on top, which acts as a base on dark garments and improves opacity. This process can be used to create individual designs or a gang sheet with multiple designs for efficiency.

- Powder Application: While the dtf ink is still wet on the transfer film, a hot melt adhesive powder is applied evenly over the printed design. Excess powder is then removed, usually by shaking or using an automated powder shaker, leaving powder only on the inked areas. This adhesive is critical for bonding the design to the fabric.

- Curing: The dtf film with the ink and powder is heated. This can be done in a curing oven, under a heat press (hovering, not full contact), or through an inline heating element on more advanced DTF systems. This step melts the adhesive powder and cures the ink, preparing the dtf transfer for application.

- Transfer: The cured dtf transfer is placed onto the garment or item. Using a heat press, the design is transferred from the PET film to the fabric with specific temperature, pressure, and time settings. After pressing, the transfer film is peeled away (either hot or cold peel, depending on the film and powder used), leaving the design bonded to the material.

This meticulous method results in extraordinary detail and vibrant, lasting colors. The powder adhesive creates a strong bond to a wide array of materials, making dtf vinyl transfers highly versatile. It's a step up from traditional transfer paper methods.

Benefits of DTF Vinyl

DTF vinyl, or more accurately dtf transfers, provide several key advantages over other custom apparel decoration methods:

- Versatility: Works effectively on light and dark vinyl or fabric surfaces, including cotton, polyester, nylon, leather, and blends. This broad compatibility is a significant plus.

- Durability: Designs withstand washing and wear exceptionally well, often outlasting the garment itself. They are more resilient than many other types of heat transfers.

- Full-Color Printing: Allows for complex, photorealistic designs, gradients, and unlimited colors in a single pass. There's no need for multiple screens or complex layering like with some craft vinyl techniques.

- No Weeding: Unlike cut transfer vinyl such as siser easyweed or holographic heat transfer vinyl, there's no tedious process of removing excess material around the design. This saves considerable time and effort.

- Soft Hand Feel: The transfers are thin, pliable, and integrate well with the fabric. They do not feel as stiff or plasticky as some older heat transfer vinyl options, providing a premium feel similar to direct-to-garment prints.

- Cost-Effective: Economical for both small custom orders and larger production runs. The ability to print gang sheets maximizes material use and reduces per-print costs.

- Fine Detail: Capable of reproducing very fine lines and intricate details that are challenging for other methods like screen printing or traditional HTV.

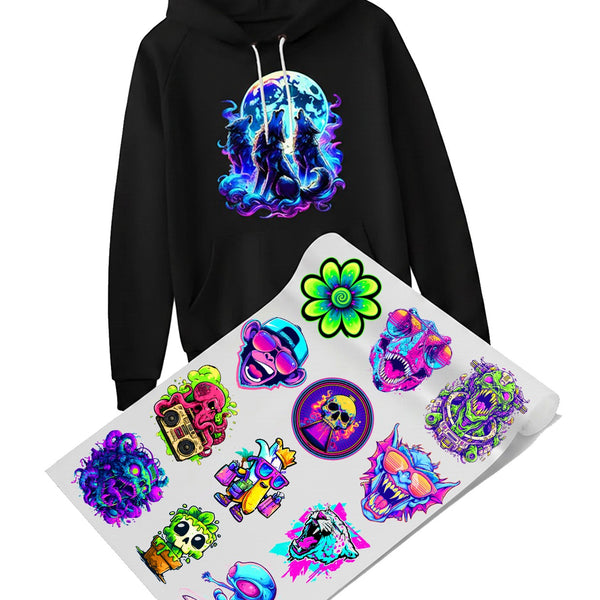

- Wide Application Range: Suitable for t-shirts, hoodies, hats, bags, and even some hard surfaces if using specialized uv dtf variations.

These benefits make dtf printing an appealing option for hobbyists using a starter pack, small businesses, and large commercial printers alike. The technology also allows for creative finishes, including those that mimic siser glitter or soft metallic effects with specialized dtf ink or films.

Many users have expressed great satisfaction. For instance, comments like "Monica je suis satisfaite" highlight the positive reception, and "sara absolutely" loves the vibrant results. This indicates a growing community of happy vinyl dtf users.

DTF vs. Other Printing Methods

How does DTF compare to other established apparel decoration techniques? Let's look at some common comparisons:

DTF vs. Screen Printing

Screen print technology is a stalwart for large volume orders but typically involves considerable setup time and cost for each color in a design. DTF allows for unlimited full-color prints without additional color setup, making it more cost-effective for small to medium batches or designs with many colors. Furthermore, DTF can often achieve finer details and gradients more easily than traditional screen printing.

While screen printing offers excellent durability with plastisol inks, DTF prints also boast impressive longevity and a softer feel. The environmental impact can also differ, with screen printing often involving more chemicals and water for screen preparation and cleanup.

DTF vs. Heat Transfer Vinyl (HTV)

Heat Transfer Vinyl (HTV), including popular options like siser easy, siser easyweed, patterned htv, or even holographic heat transfer, is limited to solid colors per layer. Complex multi-color designs require cutting and layering multiple pieces of vinyl, which can be time-consuming and result in a thicker, less flexible design. Weeding, the process of removing unwanted vinyl with a vinyl cutter, is also necessary for HTV.

DTF eliminates the need for weeding and layering for multiple colors, printing full-color designs directly onto the transfer film. DTF generally offers superior durability and a much softer hand feel compared to layered HTV. While specialty HTV like easy puff or siser easy puff offer unique textures, DTF provides broader color and detail capabilities for standard prints. Some pu heat transfer vinyl types are known for their stretchability, a quality that well-made DTF transfers also share.

DTF vs. Sublimation

Sublimation printing produces vibrant, permanent designs with an undetectable hand feel because the ink becomes part of the fabric. However, traditional sublimation transfers only work effectively on white or very light-colored 100% polyester garments or specially coated hard surfaces. It does not work on cotton or dark-colored fabrics.

DTF overcomes these limitations, as it can be applied to virtually any color fabric and a wider range of materials, including cotton, polyester, blends, and more. DTF prints a white underbase, allowing vibrant colors to show up on dark garments. While sublimation dyes the fabric, DTF applies a thin layer on top, which is still very soft and durable. Products like siser easysubli try to bridge this gap for cotton, but DTF provides a more direct, versatile solution.

DTF vs. Direct-to-Garment (DTG)

Direct-to-Garment (DTG) printing applies water-based inks directly onto the fabric, resulting in a very soft feel, especially on light garments. However, DTG requires pre-treatment for dark garments, and the printers can be expensive and require significant maintenance. DTG works best on high-cotton content fabrics.

DTF is often seen as more versatile than DTG regarding fabric compatibility, as it works well on synthetics and blends without extensive pre-treatment for every fabric type. The durability of DTF transfers is also generally considered very good, sometimes even outperforming DTG on certain fabric types, especially synthetic activewear. The initial equipment investment for DTF can be lower than high-end DTG setups, though both require a learning curve.

Getting Started with DTF Vinyl

If you are ready to try dtf printing, here's an overview of the essential equipment and supplies you will need. Many suppliers offer a starter pack to help beginners:

- DTF Printer: These are specialized inkjet printers designed to handle PET dtf film and specific dtf ink formulations. They typically include channels for CMYK and White inks.

- DTF Ink: Specially formulated pigment inks are required. These inks are designed for elasticity and vibrant color output on the transfer film.

- PET Film (Transfer Film): This is the special coated film onto which designs are printed. Films can be cold peel or hot peel, and come in rolls or sheets. Some offer a bubble free quality.

- Hot Melt Adhesive Powder: This fine powder (often a polyurethane hot melt adhesive) is applied to the wet ink on the film and acts as the bonding agent when heat pressed.

- Curing Oven or Heat Source: To melt the adhesive powder onto the inked design on the film. This can be a dedicated curing oven, a heat gun for small scale, or the hover function of a heat press.

- Heat Press: Essential for transferring the design from the dtf film to the substrate. A good quality heat press that provides consistent temperature and pressure is important.

- RIP Software (Raster Image Processor): Often necessary for DTF printers, especially for managing white ink layers, color profiles, and optimizing print layout for gang sheets. Some printers come with integrated software.

- Design Software: Standard graphic design software like Adobe Photoshop or Illustrator to create and prepare your artwork. Having a color chart for your specific dtf ink and printer setup is beneficial.

While the initial investment for a complete dtf printing system can be substantial (sometimes several thousand EUR ⬠or USD, depending on the scale), many find the versatility, quality, and efficiency of DTF transfers to be worth the cost. Alternatively, you can start by purchasing pre-made dtf transfers from a service provider before investing in your own equipment. You can find dtf vinyl transfers for a wide variety of applications.

Tips for Success with DTF Vinyl

To achieve the best results with your dtf print projects, consider these helpful tips:

- Use High-Quality Artwork: The final print quality is directly influenced by the source image. Use high-resolution images (300 DPI is often recommended) for clear, sharp dtf transfers.

- Adjust Design for Fabric Color: For dark vinyl or fabrics, a white ink underbase is critical to make colors pop. Ensure your RIP software handles this correctly.

- Follow Temperature and Time Guidelines: Different fabrics and transfer film types may require specific heat press settings for temperature, pressure, and pressing time. Always test your settings.

- Choose the Correct Peel Method: DTF film is typically either hot peel or cold peel. Using the wrong peeling method can ruin the transfer. Check manufacturer recommendations for your specific film.

- Practice Proper Printer Maintenance: Keep your DTF printer clean and well-maintained. Regular cleaning of print heads, capping stations, and wipers prevents clogs and ensures consistent print quality.

- Store Materials Correctly: DTF ink, film, and powder should be stored according to manufacturer guidelines, usually in a climate-controlled environment to prevent issues. Humidity can affect powder clumping and film performance.

- Test on Scrap Fabric: Before committing to a final garment, always do a test print and press on a scrap piece of the same or similar material. This helps verify colors and adhesion.

- Powder Application: Strive for an even coating of adhesive powder. Too little powder can result in poor adhesion, while too much can create a rough texture or affect the edges of the design.

- Consider Transfer Tape for Certain Applications: While not standard for apparel DTF, for some uv dtf applications on rigid items, a tack transfer tape like medium tack transfer tape might be used to apply the decal. Ensure it's compatible.

With practice and attention to detail, you'll be creating professional-quality custom apparel and products. The series craft approach, focusing on iterative improvement, is beneficial.

Troubleshooting Common DTF Issues

Even with the best practices, you might encounter some issues. Here are common problems and potential solutions:

- Poor Adhesion:

- Cause: Insufficient heat, pressure, or time during heat pressing. Incorrect powder application.

- Solution: Verify heat press settings. Ensure even powder coverage and proper curing of the powder before pressing.

- Colors Look Dull or Inaccurate:

- Cause: Incorrect color profiles in RIP software. Low-quality ink. Printing without a white underbase on dark fabrics.

- Solution: Calibrate your monitor and use correct ICC profiles. Use high-quality dtf ink. Ensure a sufficient white underbase is printed. Use a color chart to verify output.

- Ink Bleeding or Blurring:

- Cause: Too much ink being laid down. Film not absorbing ink correctly. Humidity too high.

- Solution: Adjust ink levels in RIP software. Try a different dtf film. Control print room environment.

- Powder Sticking to Non-Printed Areas:

- Cause: Static on the film. Film quality. Powder too fine for the conditions.

- Solution: Use an anti-static gun or brush on the film. Ensure film is clean. Try a different grade of powder.

- Transfer Cracking After Washing:

- Cause: Under-curing of ink/powder. Insufficient press pressure. Low-quality materials.

- Solution: Ensure full curing of the powder. Increase press pressure. Use quality film, ink, and powder. Allow 24 hours before washing.

Addressing these issues promptly can save materials and improve the quality of your dtf transfers. Consulting resources from your equipment supplier or online communities, where experts like Jenna Kårwik might share insights, can also be very helpful.

DTF Vinyl for Business

DTF printing isn’t just for hobbyists. Today, many businesses are adopting this technology to expand their service offerings. Its flexibility makes DTF vinyl printing especially suitable for a variety of commercial uses:

- Custom T-Shirt Shops: Easily produce one-offs or small batches with intricate, full-color designs. A print shop can greatly benefit from this flexibility.

- Print-on-Demand (POD) Services: DTF is ideal for POD due to its ability to print designs as orders come in, eliminating the need for large inventories of pre-printed items.

- Sports Team Uniforms: The durability and stretchability of dtf transfers make them suitable for athletic wear, including names, numbers, and logos on jerseys.

- Corporate Branding: Create branded apparel and promotional items like bags, hats, and aprons with consistent, high-quality logos.

- Event Merchandise: Quickly produce merchandise for concerts, festivals, and other events with vibrant, eye-catching graphics.

- Fashion Designers: Small fashion labels can use DTF for producing samples or limited-edition collections with complex designs without high setup costs.

- Online Sellers: Businesses on platforms like Etsy can offer highly personalized products using dtf vinyl transfers.

The capacity to print full-color, detailed designs with no minimum order quantity makes DTF a flexible and powerful option for businesses of all sizes. Selling dtf transfers themselves as a standalone product is also a viable business model, catering to those who have a heat press but not a full DTF setup.

Environmental Considerations

With any printing method, it is important to consider the environmental impact. While dtf printing involves plastic films (PET transfer film) and powders, the industry is making strides towards more sustainable practices.

Some manufacturers are developing biodegradable or recyclable PET films. Water-based dtf ink options are common, which are generally less harsh than solvent-based inks. Efforts are also being made to reduce waste in the powder application and curing processes.

Compared to traditional screen print methods that may use plastisol inks (containing PVC and phthalates) and require significant water for screen cleaning, DTF can sometimes offer a more contained waste stream. However, proper disposal of used films and waste powder remains a consideration. Researching suppliers who prioritize sustainability in their dtf film and ink products is a good step.

The Future of DTF Vinyl

DTF technology is still advancing, and we can anticipate continued improvements and innovations. Future developments may include:

- Faster Printing Speeds: Enhanced printer technology will likely lead to increased production capacity, making DTF even more competitive for larger runs.

- More Eco-Friendly Materials: Further development of biodegradable films, recycled content films, and greener dtf ink and hot melt powder formulations.

- Expanded Color Gamuts and Effects: New dtf ink colors, such as fluorescent or metallic options, and films that enable effects similar to holographic heat transfer vinyl or even carbon fiber textures. This could create results like soft metallic holographic heat transfer vinyl directly through DTF.

- Integration with Other Technologies: Hybrid systems that combine DTF with DTG or other printing methods for unique applications.

- Improved Software: More intuitive RIP software with advanced color management and automation features.

- Direct-to-Film for Hard Surfaces: Growth of related technologies like uv dtf, which allows for applying similar transfers to hard goods, expanding beyond textiles. This is different from traditional inkjet heat transfer paper.

- Specialty PU Heat Transfer Films: New pu heat transfer films for specific applications might emerge, working alongside the current pu heat like powders.

As the technology matures, dtf vinyl is set to become an even more powerful and accessible tool for custom apparel and product creation. The versatility it offers means it will likely continue to gain market share from older methods like inkjet heat transfer papers.

Conclusion

DTF vinyl, or more accurately the direct-to-film transfer process, marks a significant advancement in custom apparel and product printing. Its versatility across various fabrics, including dark vinyl and synthetics, coupled with its durability and stunning full-color dtf print quality, makes it a leading choice for both hobbyists and professional printing businesses.

Whether you are planning to start a custom t-shirt business, enhance your existing print shop capabilities, or simply create distinctive designs for personal use, dtf vinyl transfers offer exciting and expanding possibilities. As the technology continues to develop and refine, offering potentially bubble free films and improved dtf ink, we can expect even more innovative applications for this revolutionary printing method, making dtf on vinyl and other materials more accessible and impressive than ever. Many echo the sentiment "je suis satisfaite" with the outcomes.

Are you ready to explore what dtf vinyl printing can do for you? With the right equipment, quality supplies like dtf film and hot melt powder, and a touch of creativity, the items you can produce are truly remarkable. It's a great time to get involved with dtf transfers.