Have you ever wanted to put your designs on shirts, bags, or hats? Maybe you run a small business, or perhaps you just love making custom gifts. If so, you've probably looked into different ways to get your graphics onto fabric.

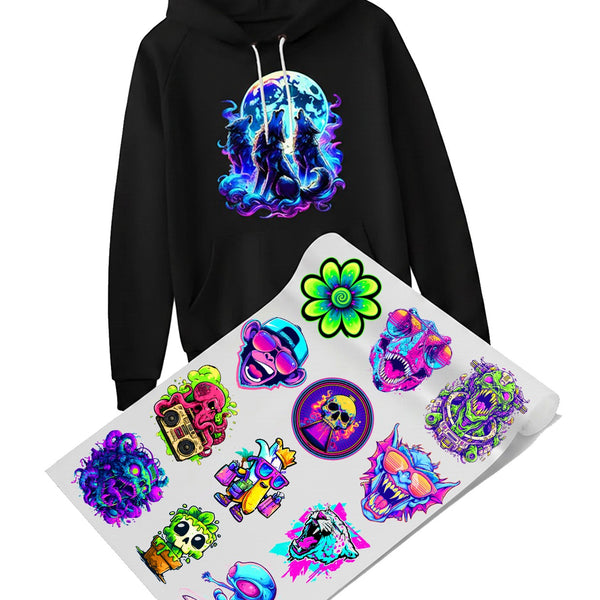

You'll learn how dtf transfers ready to press are changing the game for creators like you. These vibrant, easy-to-use graphics are making custom apparel simpler than ever with dtf transfers ready to press. This method streamlines the creation of personalized items.

What Exactly Are DTF Transfers Ready to Press?

DTF stands for Direct to Film. It's a modern printing method that is gaining popularity for its quality and versatility. Unlike older methods, DTF involves printing your design onto a special film first, which acts as the carrier for the ink.

Subsequently, this printed film transfer is used to move the design to your chosen fabric using a heat press. When we talk about dtf transfers ready to press, it means you receive the printed film with the design fully prepared. All the complex printing work, including color management and adhesive application, is already completed for you.

Your main task is to apply it using a heat press and your blank apparel or item. This approach significantly increases convenience, especially if you lack a commercial printing setup. These transfers offer a substantial improvement over traditional iron-on patches, providing professional-quality results that are soft to the touch and durable, making ready to press dtf transfers a go-to choice for many.

Many find them easier and more versatile than methods like heat transfer vinyl (HTV) or screen printing. This is particularly true for multi-color t-shirt designs or smaller production quantities. The ability to produce detailed, full-color images without extensive setup is a major advantage.

How Do These Transfers Work?

The process behind DTF transfers might seem intricate, but it's based on clever technology. Before the transfer reaches you, a specialized printer creates your design. This printer uses specific water-based inks to print directly onto a clear PET (polyethylene terephthalate) film.

After the colored inks are laid down, a white ink layer is often printed on top (which becomes the base on dark fabrics). Following the ink application, a special adhesive powder is applied to the wet ink. This powder is crucial as it's the bonding agent that helps the design stick firmly to the fabric fibers.

The powdered film then goes through a curing process. This usually involves gentle dtf heat to melt the powder and bond it securely to the ink, preparing the film transfer for application. The great part for you is that you bypass all these initial production steps.

You receive the cured transfer, often referred to as a ready-to-press dtf transfer. Your job is to apply it, which involves correctly positioning the transfer on your garment and using a heat press. The combination of dtf heat and pressure activates the adhesive, permanently bonding your design to the material for a lasting finish.

The Big Benefits: Why Choose Ready-Made DTF Transfers?

So, why are so many people, from hobbyists to established businesses, turning to these dtf transfers? There are quite a few compelling reasons. They provide a strong combination of quality, ease of use, and flexibility for various projects.

Vibrant Colors and Amazing Detail

DTF printing is recognized for its excellent color reproduction. Because the design is printed first on a film substrate, colors come out bright, rich, and true to the original digital file. This method can handle incredibly detailed graphics, photographs, and complex gradients with precision.

So, if your design features fine lines, intricate patterns, or many shades, DTF can capture it beautifully. The resulting dtf prints ready to press boast sharpness and clarity. This makes them ideal for high-impact visual branding or artistic expression.

Works on Almost Any Fabric (And Color.)

This is a significant advantage of custom dtf transfers. DTF transfers are very versatile in terms of fabric compatibility. They work wonderfully on cotton, polyester, cotton-polyester blends, tri-blends, and even nylon or leather with the correct application settings.

Furthermore, they show up perfectly on both light and dark colored garments. There's no need for a separate base layer or special treatment for dark fabrics, as the white ink underbase is part of the DTF printing process. This versatility opens up a wider range of blank apparel and items for customization.

Durability That Lasts

When applied correctly according to supplier instructions, dtf transfers are exceptionally tough. They can withstand numerous wash cycles without cracking, peeling, or significant fading. The designs also have good elasticity, stretching with the fabric, so they feel comfortable to wear and maintain their integrity.

This makes them a fantastic choice for items that will see a lot of use, like workwear, sportswear, or everyday t-shirts. Proper application using a quality heat press and adherence to care instructions are important for maximizing the longevity of the heat transfer. Many users report the transfer outlasting the garment itself.

So Easy to Apply

Compared to screen printing or the process of cutting and weeding intricate vinyl designs, applying custom dtf transfers ready to press is remarkably simple. There's no weeding of tiny, unwanted pieces of vinyl. There are no messy inks, emulsions, or screens to prepare and clean.

You just position the transfer and press it with a heat press. This ease of use makes them ideal for both beginners venturing into apparel customization and busy professionals looking for efficient production methods. The straightforward application reduces errors and speeds up workflow.

Cost-Effective, Especially for Small Runs and Gang Sheets

Traditional printing methods like screen printing often involve significant setup costs, especially for designs with multiple colors, as each color requires a separate screen. With DTF, the cost per transfer is generally consistent, whether you need one, ten, or fifty. This makes it very budget-friendly for custom one-off items, sample production, or small batch orders of ready to press dtf transfers.

You can order exactly what you need, reducing waste and minimizing upfront investment. This is particularly helpful if you are testing new t-shirt designs or catering to niche markets. Furthermore, utilizing a dtf gang sheet, where multiple designs are printed on one large film, can further reduce the unit price /per item, making even small orders very economical.

Preparing Your Artwork for DTF Transfers

Before you order custom dtf transfers, preparing your artwork correctly is crucial for the best results. Most suppliers will have specific guidelines, but some general principles apply. Pay attention to these details when you create dtf designs.

Firstly, high-resolution artwork is essential. A resolution of 300 DPI (dots per inch) at the intended print size is standard. Vector files (like AI, EPS, or SVG) are often preferred because they can be scaled without loss of quality, but high-quality raster files (like PNG with a transparent background) are also commonly accepted.

Ensure your design has a transparent background unless the background is part of the print. For PNG files, this means saving it without a solid color backdrop. If you have very fine details or text, make sure they meet the minimum thickness requirements specified by your dtf transfer supplier, as extremely thin lines may not print or transfer well.

Color mode is another consideration. While you might design in RGB, some printers operate in CMYK. Check with your supplier if you need to convert your files. Good communication about artwork specifications will help avoid printing issues and ensure your dtf transfers ready to press look exactly as you envisioned.

Understanding DTF Gang Sheets for Efficient Ordering

If you plan to order multiple designs or need many copies of smaller designs, understanding how a dtf gang sheet works can save you money. A dtf gang sheet allows you to arrange several different designs, or multiple copies of the same design, onto a single large sheet of transfer film. You pay for the sheet, not necessarily each individual design on it.

This method is highly efficient for maximizing your print area and reducing the cost per transfer. For example, instead of ordering ten small individual logo transfers, you could fit them all onto one custom dtf gang sheet, along with other designs you might need. Many suppliers offer an online tool to create dtf gang layouts easily, or you can submit a pre-arranged file.

Using dtf gang sheets is a smart way to get cheap dtf transfers ready to press without compromising on quality. It's perfect for businesses that produce a variety of custom items or for individuals planning multiple projects. Always check the usable print area for the gang sheets offered by your supplier to plan your layout effectively.

Getting Started: Your Guide to Using dtf transfers ready to press

Ready to try applying your first dtf transfer? It's more straightforward than you might imagine. Having the correct tools and following a few simple steps for dtf transfer how to press will help you achieve professional-looking results consistently.

What You'll Need

Here's a basic list of what you should have on hand for your dtf heat transfer application:

- A heat press: This is critically important for consistent heat and even pressure. While a home iron might seem like an alternative, a heat press delivers far superior and more durable results for any press dtf transfer.

- Your DTF transfer: The main component, your custom dtf design printed on film.

- The garment or item (blank apparel): Ensure it's clean, dry, and suitable for heat application. Popular choices include t-shirts, hoodies, and tote bags.

- Teflon sheet or parchment paper: This protects your garment from direct contact with the heat platen and prevents ink from transferring to your press.

- Heat resistant tape (optional): Useful for securing the transfer in place on some items, especially non-flat surfaces.

- A flat, sturdy surface for your heat press.

Step-by-Step Application Guide

Always consult the specific instructions provided by your dtf transfer supplier, as temperature, time, and pressure settings can vary. However, here's a general guide on dtf transfer how to use them:

- Prepare your heat press. Set it to the recommended temperature and time for your specific dtf transfers and fabric type. Typical ranges are often between 280-320°F (138-160°C) for 10-20 seconds. Set your pressure as well; medium to firm pressure is common for dtf heat applications.

- Pre-press your garment. Place your item on the lower platen of the heat press and press it for 5-10 seconds. This crucial step removes moisture and any wrinkles, creating a smooth, flat surface for optimal transfer adhesion.

- Position the transfer. Carefully place the dtf transfer onto the garment, with the design side (ink side) facing down against the fabric. You can usually see through the clear film to align it accurately. If needed, use heat-resistant tape to secure it, especially on slippery fabrics.

- Press according to instructions. Cover the transfer and garment area with your Teflon sheet or parchment paper. Close the press and apply heat and pressure for the recommended duration. Avoid moving the garment or press during this time.

- Peel the film. This is a critical step with specific requirements. Some transfers are "cold peel," meaning you must let the transfer and garment cool down completely before attempting to peel the film. Others are "hot peel" or "warm peel," allowing you to peel the film immediately or shortly after pressing while still warm. Your supplier will specify the correct peel type for their press dtf transfers. Peel slowly and steadily at a consistent angle.

- Optional second press (post-press). After peeling the film, some users like to perform a quick second press for 2-5 seconds. Cover the design directly with a Teflon sheet or parchment paper. This can sometimes improve the matte finish, feel (softness), and overall durability of the dtf print.

Below is a general table for common DTF application settings. Always refer to your supplier's specific recommendations.

|

Fabric Type |

Temperature Range (°F) |

Temperature Range (°C) |

Time (Seconds) |

Pressure |

Peel Type |

|

100% Cotton |

300-320°F |

149-160°C |

10-15 |

Medium-Firm |

Supplier Specific (Hot/Warm/Cold) |

|

Polyester & Blends |

280-300°F |

138-149°C |

10-15 |

Medium |

Supplier Specific (Hot/Warm/Cold) |

|

Tri-Blends |

270-290°F |

132-143°C |

10-12 |

Medium |

Supplier Specific (Hot/Warm/Cold) |

|

Nylon (Test First) |

260-280°F |

127-138°C |

8-12 |

Light-Medium |

Supplier Specific (Cold Recommended) |

Tips for a Perfect Press Every Time

A few additional tips can make a significant difference in achieving flawless results with your dtf ready to press transfers:

- Ensure your heat press provides accurate and consistent temperature across the platen. Using a heat gun or temperature strips to check your heat press calibration periodically is a good practice.

- Use consistent and appropriate pressure. Uneven pressure can lead to parts of the transfer not adhering properly or an inconsistent finish.

- Always, always follow the supplier's guidelines for their specific transfers. They know their product chemistry and dtf heat transfer parameters best. These instructions often include details for various fabrics.

- If you're unsure or working with a new fabric type, always perform a test press on a scrap piece of the same material or an inconspicuous area of the garment first.

- Allow the garment to cure for at least 24 hours after pressing before washing it. This gives the adhesive ample time to fully set and bond with the fabric fibers.

- When peeling, if the transfer is lifting, stop and re-press for a few more seconds. Ensure the item has cooled sufficiently if it's a cold peel transfer.

What Can You Create with These Transfers?

The creative possibilities with dtf transfers ready to press are extensive. Because DTF technology works effectively on so many different materials and fabric colors, you can truly get inventive. Popular items include custom t-shirts, hoodies, and sweatshirts, which are excellent for sports teams, company branding, event merchandise, or expressing personal style with unique t-shirt designs.

But don't limit your imagination there. Think about accessories like hats and caps; many dtf transfers are flexible enough for slightly curved surfaces. Custom tote bags and drawstring bags are another excellent canvas for your designs, making great promotional items, reusable shopping bags, or personalized gifts for occasions like Father's Day or birthdays. Even a July dtf themed beach bag can be a fun project.

You can also consider items for home decor. Custom pillowcases, aprons, tea towels, or even small fabric banners can be beautifully decorated with a dtf transfer. Some people even use DTF on items like koozies, mousepads, and more. Whether it's for a custom dtf gang project or a single special item, these transfers make personalization accessible for many different products, including long sleeve shirts and other blank apparel.

Finding Quality Suppliers for Your Transfers

Not all DTF transfers are created equal. Finding a reliable supplier is important for getting good results and consistent quality with your ready to press dtf transfers. Look for companies that are transparent about their printing process, the inks they use, and the film and adhesive materials.

Check for reviews and testimonials from other customers. See if they offer a sample pack, sometimes even a free sample, so you can test their quality before placing a larger order or committing to a custom dtf gang sheet. Inquire about their turnaround times, typically quoted in business day increments, and whether they offer expedited options or free shipping on certain order values.

Good communication is also a sign of a quality supplier. They should be ableable to answer your questions about dtf transfer how to use their products and provide support if you encounter issues. A supplier focused on helping you succeed is a great partner to have. You might search for "dtf transfers ready to press near me" or "custom dtf transfers ready to press near me" to find local options, or explore reputable online vendors who ship nationwide.

When you order custom dtf transfers, check their artwork requirements carefully. Some suppliers offer an online tool to create dtf layouts and will show a quick view of the design before you finalize. See if they have options for premade dtf transfers or premade dtf gang sheets if you need generic designs quickly. Consider if they have an affiliate program if you plan to refer others.

Caring for Your DTF-Printed Garments

To maximize the lifespan of your custom dtf printed apparel, proper care is essential. While dtf transfers are known for their durability, following a few simple guidelines will keep them looking great. These care instructions are generally similar to those for other high-quality printed garments.

Wait at least 24-48 hours after pressing before the first wash. When washing, turn the garment inside out. This minimizes friction on the design during the wash cycle.

Use a mild detergent and wash in cold or cool water. Avoid using bleach or harsh chemicals, as these can degrade the print and fabric over time. If possible, opt for a gentle wash cycle. When drying, it's best to hang dry or tumble dry on a low heat setting, again with the garment inside out if possible. High heat from dryers can be detrimental to the adhesive and elasticity of the transfer over many cycles.

If you need to iron the garment, do not iron directly over the dtf transfer. Iron around the design or turn the garment inside out and iron on a low setting, avoiding prolonged heat on the transferred area. By following these care tips, your dtf prints will remain vibrant and intact for a long time.

Troubleshooting Common DTF Application Issues

Even with the best dtf transfers ready to press, you might occasionally encounter an issue. Here are some common problems and how to address them:

- Transfer Not Sticking Completely: This is often due to insufficient pressure, incorrect temperature, or too short a press time. Double-check your heat press settings against the supplier's recommendations. Ensure your press is providing even pressure. Pre-pressing the garment to remove moisture is also key.

- Edges of the Design Lifting After Peeling: This could be related to peel type (peeling too hot for a cold peel, or vice-versa), or insufficient pressure at the edges. Ensure you are peeling at the correct temperature and try increasing pressure slightly. A quick post-press for 2-5 seconds can sometimes help seat the edges better.

- Dye Migration or Scorching on Polyester: Polyester fabrics are prone to dye migration (fabric dye bleeding into the transfer) or scorching at high temperatures. Use a lower temperature setting as recommended for polyester (usually around 270-280°F) and a shorter press time. A Teflon sheet or cover sheet is essential.

- Shiny Outline Around the Transfer: This can sometimes happen from the adhesive melting slightly beyond the design edge. A post-press with a matte finishing sheet or parchment paper can often reduce this. Also, ensure you're not using excessive pressure.

- Colors Appear Dull After Pressing: This could be an issue with the transfer quality itself, or incorrect press settings (too high temp can sometimes affect certain colors). If it's consistent, discuss with your dtf transfer supplier. Ensure your artwork was high resolution.

Always perform a test press on scrap material if you're trying new transfers or fabrics. This helps you dial in your settings before committing to your final blank apparel. Understanding how to troubleshoot can save you time and materials.

A Note on UV DTF Transfers and UV Stickers

While this guide focuses on dtf transfers for fabric, you might also encounter terms like UV DTF transfers or UV stickers. It's helpful to understand that these are a related but different technology, primarily for hard surfaces. UV DTF involves printing with UV-curable inks onto a special adhesive-backed film, creating a durable, vibrant sticker-like application.

These UV stickers are excellent for decorating items like mugs, tumblers, phone cases, glass, wood, metal, and other non-fabric items. They offer great adhesion and are often waterproof and scratch-resistant. While the "DTF" acronym is shared, the application process and end-use are distinct from the textile dtf heat transfers we've been discussing.

So, if your project involves customizing hard goods rather than apparel, UV DTF could be an interesting option to explore. Just remember they are not typically applied with a heat press in the same way as fabric dtf transfers. They are usually applied like a decal or sticker, with a firm rub-down, and then the carrier film is peeled away.

Common Questions People Ask

When you're new to using a dtf transfer ready to press, questions naturally arise. Here are a few common inquiries people often have about this printing method:

How long do dtf transfers really last? With proper application using a quality heat press and appropriate care (like washing inside out on a cool setting and avoiding harsh detergents or bleach), high-quality custom dtf transfers can typically last for 50 washes or more. They often outlive the garment itself. The durability is one of their key selling points when compared to some other DIY decoration methods.

Can I use a home iron instead of a heat press for dtf transfers? It's generally not recommended for professional, consistent, or long-lasting results with any ready to press dtf transfers. A home iron doesn't provide the consistent, even heat and, critically, the sustained, even pressure needed for the adhesive to properly bond across the entire design. You might get some temporary adhesion, but it likely won't be durable or wash well. Investing in even a small hobby heat press makes a substantial difference for any kind of heat applied transfer, ensuring the dtf heat transfer adheres correctly.

How should I store unused dtf transfers or a dtf gang sheet? Keep them in a cool, dry place, away from direct sunlight and high humidity. Lay them flat if possible, often in the packaging they arrived in, or store them rolled loosely (design side out, as some suppliers advise) if flat storage isn't an option. Avoid creasing, folding, or stacking heavy items on top of them. Properly stored, unused transfers can last for many months, retaining their quality until you're ready to press dtf transfer designs.

Are they an environmentally friendly option? The technology is continuously improving. Many DTF printers utilize water-based inks, which are generally considered better for the environment than solvent-based inks. The process can also be less wasteful than traditional screen printing for small runs or one-offs, since there's no screen preparation, emulsion, or extensive color mixing and cleanup for each individual job. Some PET films used for the dtf transfer are also recyclable, though you'd need to check local facilities. Always look for suppliers who are conscious about their materials and processes.

What is the difference between hot peel and cold peel dtf transfers? The main difference is when you remove the carrier film after pressing. For hot peel transfers, you peel the film off almost immediately after opening the heat press while the design and garment are still very hot. For cold peel dtf transfers, you must wait until the design and garment have cooled down completely before removing the film. Attempting to peel a cold peel transfer while hot can ruin the application, and vice-versa. Always follow your supplier's specific instructions, as this is critical for success.

Conclusion

Customizing apparel and various other items has never been more accessible, largely thanks to innovations like dtf transfers ready to press. They provide a fantastic combination of brilliant color, impressive fine detail, and robust durability. A key advantage is their versatility, working effectively on a wide array of fabrics and colors.

Whether you're a dedicated hobbyist, a small business owner looking to offer custom merchandise, or just someone with a creative idea for a t-shirt design or personalized gift, using dtf transfers ready to press can help you bring your visions to life. The process is relatively simple, efficient, and cost-effective, especially when utilizing options like a dtf gang sheet for multiple designs. Considering the ease of use and professional results, these film transfer solutions are definitely worth exploring for your next creative project.

From custom dtf creations for a special day dtf event like Father's Day to outfitting a team, the quality of ready-to-press dtf transfers can elevate your items. Many find that sourcing cheap dtf transfers ready to press allows for profitable ventures or affordable personal projects. As you become more familiar with how to press dtf transfers, you'll appreciate their contribution to the world of custom printing.