Direct-to-Film (DTF) transfers are taking the world of custom apparel and fabric design by storm. This innovative technique allows you to apply high-quality, vibrant designs to garments quickly and efficiently. But what exactly are DTF transfers, and how can you use them for your projects? Here’s everything you need to know about this cutting-edge method, made simple and easy to understand.

For more in-depth information on DTF transfers, check out the original source here.

What Are DTF Transfers?

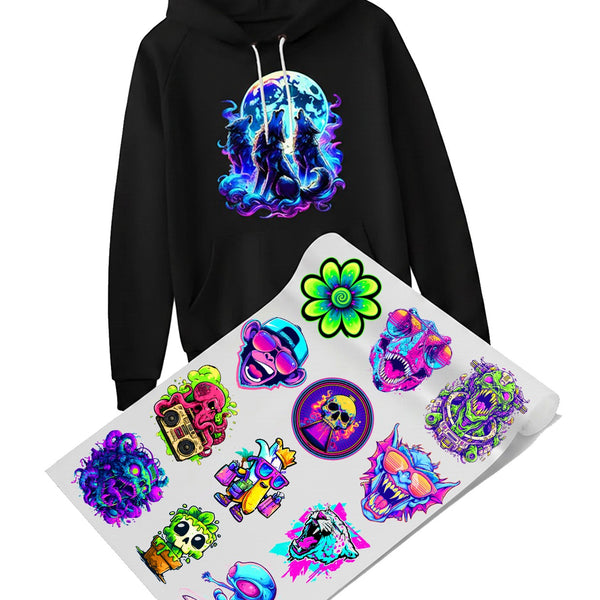

DTF transfers, or Direct-to-Film transfers, are a method for transferring colorful and intricate designs onto different fabrics. This process uses a specialized film and heat press to apply your design to garments, providing high-quality results with less effort compared to traditional methods like screen printing.

Whether you’re working with cotton, polyester, or fabric blends, DTF transfers offer a reliable way to produce durable and vibrant prints that look professional and stand the test of time.

How Does the Process Work?

The DTF process involves a few simple steps:

- Print the Design

- Using a special DTF printer, your artwork is printed onto a PET (polyurethane terephthalate) film in reverse order. A white backing is added during the printing process for extra vibrancy.

- Apply Adhesive Powder

- After printing, a hot-melt adhesive powder is applied to the wet ink on the film. This powder helps the design adhere to the fabric during pressing.

- Cure the Film

- The powdered film is heated to activate the adhesive layer. This step ensures the design is perfectly prepared for transfer.

- Press Onto Fabric

- Place the film onto the garment and use a heat press to apply the design to the fabric. Once pressed, peel away the film, leaving the design fused to the material.

This process is easy and doesn’t require extensive preparation, making it ideal for both beginners and experienced designers.

Benefits of DTF Transfers

DTF transfers are becoming a popular choice for custom apparel, and for good reason. Here's why they stand out:

1. Works on Many Fabrics

One of the biggest advantages of DTF transfers is their wide compatibility. They work well on:

- Polyester

- Cotton

- Fabric blends

- Textures like mesh or fleece

This versatility makes DTF transfers a go-to option for various projects, from sports uniforms to everyday t-shirts.

2. Vivid, Detailed Prints

DTF transfers deliver sharp, vibrant designs with excellent detail. Unlike older methods, they can handle gradients, tiny text, and intricate shapes with ease.

3. Durable Results

The heat-activated adhesive ensures the design bonds firmly to the fabric. With proper care, DTF prints can withstand many washes without cracking, fading, or peeling.

4. No Cutting or Weeding Needed

With processes like vinyl cutting, you need to carefully remove excess material from your design (weeding). DTF transfers eliminate this step entirely, saving time and effort.

5. Cost-Effective for Bulk Orders

Gang sheets, which allow multiple designs on one transfer sheet, make DTF transfers highly cost-effective. Batch printing is easy and keeps production costs low, especially for businesses.

6. Soft and Comfortable Printing

DTF transfers result in a finished product that feels smooth and lightweight on fabrics. Unlike some thick printing methods, these transfers maintain the material's flexibility and comfort.

Common Applications of DTF Transfers

DTF transfers are perfect for a wide range of projects. Here are some of the most popular ways to use them:

1. Sports Uniforms and Jerseys

With the ability to print detailed names, numbers, and logos, DTF transfers are ideal for customizing team uniforms. Whether it’s soccer jerseys or basketball tanks, they ensure a professional look with lasting durability.

2. Workwear and Promotional Items

For businesses, DTF transfers offer a way to create branded uniforms, hats, or tote bags. They work equally well for promotional merchandise like giveaway t-shirts, ensuring your designs look polished and clear.

3. Custom Apparel for Events

From family reunions to charity runs, DTF transfers provide an easy way to customize clothing for special occasions. They allow for quick production of matching shirts, hoodies, or caps.

4. Ecommerce and Small Businesses

If you run an online store, DTF transfers can help expand your product line. They’re great for creating unique, made-to-order apparel without investing heavily in equipment.

5. One-Off Personal Projects

For hobbyists and DIY enthusiasts, DTF transfers provide a simple, affordable way to personalize items like pillows, tote bags, or aprons.

Tips for Using DTF Transfers

While the DTF process is simple, there are a few tips to ensure the best results:

1. Use High-Quality Films and Printers

Invest in good-quality transfer films and ensure your printer is calibrated correctly for sharp, clean prints.

2. Prepare the Fabric

Before applying the transfer, use your heat press to preheat the fabric. This removes any wrinkles or moisture that could affect the adhesive bond.

3. Follow Manufacturer’s Guidelines

Every transfer film or printer may have specific recommendations for temperature, pressure, and time. Follow those instructions carefully to avoid errors.

4. Store Transfers Properly

Keep unused transfers in a cool, dry place to prevent damage. They’ll remain in good condition for use later.

Why Choose DTF Virginia for DTF Transfers?

At DTF Virginia, we specialize in custom DTF printing for polyester, cotton, and blended fabrics. Here’s why clients choose us again and again:

- Premium Quality: Using top-tier technology, we create vibrant designs that are durable and ready to last.

- Wide Fabric Compatibility: From lightweight t-shirts to heavy-duty workwear, we customize products for every need.

- Bulk-Friendly Options: Our gang sheets and flexible printing options make us a cost-effective choice for businesses.

- Expert Support: Need help with design or printing? We offer guidance at every step of the process.

Whether you’re creating custom apparel for an event or restocking your online store, DTF Virginia delivers solutions tailored to your goals.

How to Care for DTF Printed Garments

To keep your DTF-printed items looking fantastic, follow these care tips:

- Wait 24 hours before the first wash after applying the transfer.

- Use cold water and mild detergents when washing.

- Avoid bleach, fabric softeners, or dry cleaning.

- Turn garments inside out before washing to preserve the print.

- Use low heat for drying or air-dry for the best results.

With proper care, your garments will remain vibrant and intact for years.

Final Thoughts

DTF transfers have redefined how we customize garments. They’re versatile, easy to use, and deliver high-quality results on a variety of fabrics. Whether you’re running a business or working on a personal project, DTF transfers provide a cost-effective and professional way to make your designs stand out.

For more detailed information or to explore DTF products further, visit Heat Transfer Warehouse’s guide. And when you’re ready to bring your vision to life, reach out to DTF Virginia for vibrant, durable, and custom designs!