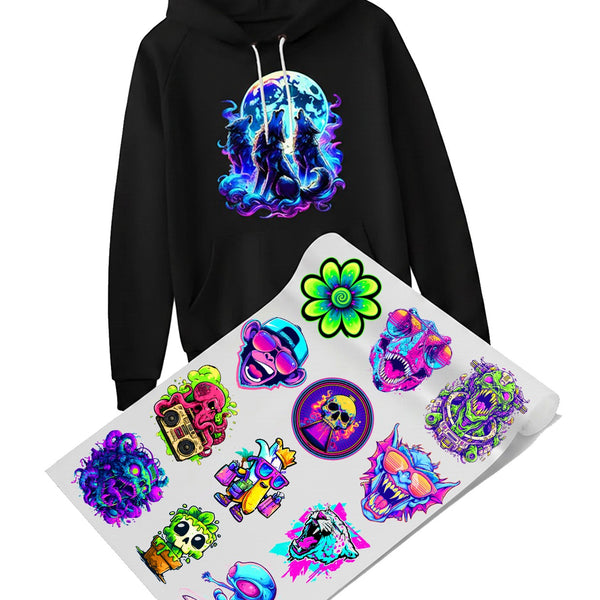

Have you heard the buzz about the incredible dtf transfer sheet? It's a hot topic in custom printing, and you might be wondering what makes it so special. Can a dtf transfer sheet truly transform how you create vivid, long-lasting designs on various items?

It's common to feel a bit overwhelmed by new printing technologies. You might be asking if this method suits your hobby, small business, or creative projects. You've come to the right spot to learn all about it and see if dtf transfers are right for you.

What Exactly is a DTF Transfer Sheet Anyway?

Let's simplify what a dtf transfer sheet is. DTF means Direct-to-Film. The core idea is printing your design onto a specific film, which is the dtf sheet itself.

This film isn't ordinary; it's a specially coated PET (polyethylene terephthalate) film. PET is chosen for its dimensional stability under heat and its excellent ink receptivity. This film is crafted to hold the ink precisely and then transfer it cleanly to your item when you apply heat and pressure with a heat press.

Consider this film the temporary home for your designs before they permanently adorn fabric or other substrates. Unlike methods where ink hits the garment directly, DTF relies on this film. This intermediate step provides many of DTF's advantages and opens new creative avenues. For instance, a dtf gang sheet allows multiple designs to be printed on a single large film, maximizing material use and efficiency for businesses that need to start saving on costs.

These films can come in different types, such as cold peel or hot peel, affecting how soon you remove the film after pressing. Some films also offer a gloss or matte finish to the final transfer, giving you more control over the aesthetic of your dtf product.

The Magic Behind the DTF Process

How does a digital design transform into a stunning print on a t-shirt using a dtf transfer sheet? It's a multi-stage process. First, your graphic is printed onto the PET film, the dtf sheet, using specialized DTF pigment-based inks. These inks are formulated for vivid colors and strong adhesion.

After the colored inks (Cyan, Magenta, Yellow, Black) are applied, a layer of white ink is typically printed over them. This white ink is essential, particularly for printing on dark-colored blank apparel. It acts as an opaque underbase, allowing the colors to appear bright and true, regardless of the fabric's shade, giving you sharp details.

The next vital component is a special hot-melt adhesive powder. While the inks on the dtf film are still wet, this fine polyurethane powder is applied over the printed design. The powder clings only to the wet ink, not the untreated areas of the film; excess powder is then removed, often by shaking or an automated system.

Following powder application, the dtf transfer sheet undergoes a curing stage. This involves heating the film, which melts the adhesive powder, causing it to fuse with the ink and form a smooth, flexible adhesive backing. This can be done in a curing oven, a heat tunnel, or sometimes with the hover function of a heat press. Now your transfers dtf are almost ready.

The last step is using heat presses for application. The cured dtf gang sheet, potentially holding multiple designs, is placed onto the garment. The heat press applies controlled temperature and pressure, activating the adhesive and bonding the ink securely to the fabric fibers. After pressing and cooling (depending on if it's a hot, warm, or cold peel film), the PET film is peeled away, leaving behind a durable and sharp design from your gang sheet dtf.

Why Everyone's Talking About Using a DTF Transfer Sheet

There are solid reasons for the growing popularity of the dtf transfer sheet in custom decoration. DTF consistently delivers impressive results, a major factor being the fantastic color vibrancy it offers. This allows for a wide color gamut in your prints.

Since the inks, bonded by the adhesive layer, rest on the fabric's surface instead of deeply soaking in, colors appear exceptionally bright and faithful to the original digital design. This applies even to complex gradients, photographic reproductions, and designs with very small text. For further exploration of color theory, you might consult the MoMA color guide for insights.

Versatility is a significant advantage of any dtf product. DTF transfers are compatible with a broad array of fabrics, including cotton, polyester, cotton/poly blends, nylon, and leather. This flexibility allows for decorating diverse items from t-shirts, long sleeve shirts, and hoodies to hats and bags. Some even use UV DTF, a related technology, for custom stickers on hard goods.

Durability is another strong point. Correctly applied quality dtf transfers boast excellent wash resistance and stretchability. They can endure numerous wash cycles without cracking, peeling, or fading, often lasting as long as the garment itself. The print generally has a soft feel, particularly after the initial wash, much lighter than some older transfer techniques.

A huge benefit for many is the elimination of weeding. Unlike using a vinyl cutter for heat transfer vinyl, where removing excess material is necessary, DTF prints your design precisely as intended. This significantly reduces labor, especially for intricate designs or orders with multiple designs on a dtf gang sheet.

This efficiency makes complex, multi-color graphics more practical and economical, particularly for small production runs. There's no need for multiple screen setups or careful alignment of vinyl layers. Everything is printed in one pass on the dtf transfer sheet, simplifying the creation of gang sheet transfers.

DTF Transfers vs. Other Customization Champs

How does a dtf transfer sheet stack up against other popular methods for customizing apparel and goods? Each technique has its strengths, but DTF brings a compelling mix of advantages to the table. Understanding these differences can help you choose the best method for your specific needs when considering dtf gang sheet printing.

DTF vs. Screen Printing

Screen printing remains a go-to for its robustness and economy in large volume production. It produces vivid prints by forcing ink through a prepared screen stencil. However, preparing screens for each color is labor-intensive and increases costs for small orders or designs featuring many colors.

In contrast, a dtf transfer sheet handles full-color, intricate graphics immediately, without needing separate setups for each color. This makes dtf gang sheet printing perfect for small quantities, personalized items, and designs rich in colors or gradients. The upfront cost for a complete DTF system can also be less than that for a multi-color screen printing setup, although screen printing excels for specific spot colors or specialty inks not easily replicated by DTF.

Using a heat transfer gang sheet with DTF allows for printing multiple different designs at once, which is very efficient. This contrasts with screen printing, where each design typically requires its own screen unless ganged in a more complex way. Screen printing can also produce stock transfers, which are then applied with heat.

DTF vs. DTG (Direct-to-Garment)

DTG printing applies water-based inks straight onto the fabric, similar to how an inkjet printer works on paper. This method yields lovely, soft prints, particularly on 100% cotton blank t-shirts. However, DTG usually necessitates pre-treatment for dark garments to achieve color brightness and proper ink adhesion.

DTG performs best on natural fibers like cotton. A dtf transfer sheet often bypasses extensive pre-treatment on various fabrics and shows excellent results on polyester and blends, materials where DTG might face challenges. For those looking for special effects, glitter dtf transfers are available, offering sparkle that standard DTG cannot match.

The wider material compatibility and often superior durability on synthetics give dtf transfers printed this way an advantage. While DTG provides an extremely soft hand, the versatility and vibrancy of DTF, including options like glitter dtf, make it very appealing. Custom dtf transfers are a popular choice for varied apparel.

DTF vs. Heat Transfer Vinyl (HTV)

Heat transfer vinyl (HTV) requires cutting designs from sheets of colored vinyl, like siser easy puff or siser holographic, and then applying them with dtf heat. It is widely used for names, numbers, and simpler graphics. However, HTV is constrained by the available vinyl colors, and layering multiple colors can result in bulky, time-intensive applications.

The meticulous weeding of complex designs from transfer vinyl is a common frustration. DTF transfers completely bypass weeding and enable full-color, highly detailed photographic designs with a softer hand than most layered vinyl. For instance, while HTV offers effects like easy puff directly, achieving full color with similar ease is DTF's strength.

The easy application process for a dtf sheet with a complex image is typically faster than multi-layer HTV. This makes creating custom dtf gang sheets with varied designs more efficient than managing multiple HTV cuts and layers. For businesses wanting to start saving time and labor, DTF is a strong contender.

DTF vs. Sublimation

Sublimation printing yields extremely vivid, permanent prints with no discernible hand feel because the ink gasifies and dyes the fabric fibers directly. While this sounds ideal, sublimation is mainly effective on white or very light-colored polyester fabrics or specially poly-coated hard surfaces. Many people use sublimation for items that are not apparel.

Sublimation ink is transparent, so it doesn't show up on cotton or dark-colored materials. This limitation is where the dtf transfer sheet demonstrates its strength, providing vibrant, full-color prints on cotton, dark fabrics, and a broader range of materials that sublimation cannot accommodate. UV DTF transfers, often called dtf stickers, are a different but related technology that works well on various hard, non-porous surfaces regardless of color.

While sublimation is unmatched for breathability and permanence on polyester, DTF, including press dtf transfer methods, offers far greater versatility across different substrates. This makes gang sheet transfers made with DTF suitable for a much wider variety of projects. If you need transfers for hard goods, UV dtf might be the answer.

Here's a quick comparison:

|

Feature |

DTF Transfer Sheet |

Screen Printing |

DTG |

HTV Vinyl |

Sublimation |

|

Fabric Versatility |

Excellent (Cotton, poly, blends, darks, lights). |

Good (Varies by ink). |

Best on cotton; pre-treat for darks. |

Good (various types for different fabrics). |

Polyester only (light colors). |

|

Color Vibrancy |

Excellent. |

Excellent. |

Good to Excellent (best on white). |

Good (solid colors). |

Excellent (on poly). |

|

Detail & Complexity (Small text, photos) |

Excellent (photographic, small text capable). |

Good (improves with screen mesh). |

Excellent (photographic). |

Fair to Good (weeding limits detail). |

Excellent (photographic). |

|

Durability |

Very Good to Excellent. |

Excellent. |

Good. |

Good to Very Good. |

Excellent (permanent). |

|

Hand Feel |

Soft to Medium. |

Varies (can be heavy). |

Very Soft. |

Varies (can be stiff/rubbery). |

None (ink is in fabric). |

|

Small Runs/One-Offs |

Excellent, especially with a gang sheet dtf. |

Costly. |

Good. |

Good. |

Good. |

|

Weeding Required |

No. |

N/A (screen prep). |

No. |

Yes. |

No. |

|

Initial Equipment Cost |

Moderate to High. |

Moderate to Very High (multi-color). |

High. |

Low to Moderate (cutter & press). |

Low to Moderate. |

Getting Your Setup for DTF Transfer Sheet Projects (Or Just the Sheets.)

Are you motivated to explore dtf transfers? You generally have two primary options. You can invest in a complete DTF printing system, or you can order custom dtf gang sheets or individual transfers from a specialized printing service.

If you are considering an in-house DTF operation, be prepared for several key equipment and supply purchases. This includes a dedicated DTF printer, distinct from standard inkjet or sublimation printers, built for PET films and specific DTF inks. You'll also need the dtf heat transfer inks themselves (CMYK and White), the DTF film (your dtf sheet), and the crucial hot melt adhesive powder.

A curing method for the powder (like a curing oven, shaker/dryer unit, or heat press with hover function) and a dependable heat press for the final application are also necessary. Adequate space and good ventilation, especially for the powdering and curing steps, are important considerations for safety and quality. Regular printer maintenance is also part of owning the system for your dtf gang.

This path provides the most control and flexibility but requires a significant initial investment and a period of learning. It's often chosen by businesses that aim to produce transfers gang printed in volume. This way, they can produce custom dtf transfers on demand.

What if investing in all this equipment isn't feasible? There's excellent news. Numerous companies provide dtf gang sheet printing services. You can upload your designs, often using an online gang sheet builder or sheet builder tool, and they will print the dtf transfers printed for you, delivering them ready for application. Some companies offer fast delivery and even free shipping on qualifying orders; check their cut-off times, often listed by pm est for same business day processing.

This is a superb choice for smaller businesses, hobbyists, or anyone desiring high-quality DTF results without the equipment expense and maintenance. All you need is a reliable heat press. When choosing a service for your gang sheet heat transfer, look for positive reviews, clear communication, and good print quality on their samples, hoping their satisfaction guaranteed promise holds true.

You can create an online gang sheet by arranging multiple designs on a single sheet layout. This online gang method is cost-effective, as the price is often by the dtf sheet rather than per design, calculated by the square inch or linear foot. Always place order carefully to maximize your print area for your dtf gang sheet.

Your Step-by-Step Guide to Applying DTF Transfers

You've got your dtf transfer sheet, either from your own printer or a dtf gang sheet printing service. Now, it's time to effortlessly apply it. The application is generally simple, but precision yields the best results for your dtf transfers dtf.

Begin by preparing your blank apparel or other item. Pre-press it for about 5-7 seconds using your heat press. This step removes moisture and wrinkles, creating an ideal flat surface for the transfer to adhere correctly.

Allow the item to cool slightly, then carefully position your dtf gang sheet or individual transfer onto the garment, with the ink side facing down. If you're concerned about movement, heat-resistant tape can secure the transfer. Double-check its alignment and placement for perfect positioning of your heat transfer gang sheet.

Correct heat press settings are vital for a successful press dtf transfer. Temperature, time, and pressure (usually medium to firm) depend on the specific DTF film, powder, inks, and fabric. Always consult your transfer supplier's guidelines. Typical settings might be 280-325°F (138-163°C) for 10-15 seconds, but confirm this information before you press heat.

After the initial press heat application, the next step varies based on whether your transfers are hot peel, warm peel, or cold peel. This indicates the film's temperature at removal. Hot peel means removing the film almost immediately; warm peel involves a short wait (5-15 seconds); cold peel requires the transfer to cool completely.

Peeling technique is also important. Peel smoothly and consistently, usually at a low, flat angle. If any part of the design lifts with the film, stop. Your press settings might need adjustment—more time, higher temperature, or increased pressure. Many quality dtf transfers are warm or hot peel for faster production and fast shipping of finished goods.

Once the film is successfully removed, a second press is highly recommended for your dtf product. Place a protective sheet (parchment paper or a Teflon sheet) over the design and press again for 5-10 seconds using the same temperature. This second press enhances washability, durability, and can give the print a softer, more matte finish. Your custom DTF creation is now complete.

Pro Tips for Perfect DTF Results Every Time

Achieving perfect results with every dtf transfer sheet project involves attention to detail. Consistency and high-quality materials are paramount. Strive to optimize these aspects for every job involving transfers custom made with DTF.

The quality of your DTF film, inks, and adhesive powder directly influences the final outcome and the vivid colors of your design. While less expensive materials might seem economical initially, they can result in poor adhesion, cracking, or lackluster colors. Investing in reputable supplies from a good supplier of dtf gang means your prints will impress and endure, delivering true quality dtf.

Your heat press is a critical tool for applying a gang sheet dtf. Confirm it's accurately calibrated. Consistent temperature and even pressure across the platen are essential for good adhesion of the entire transfer size. Uneven heating can cause parts of the dtf gang sheet transfers to fail. You can use heat strips to verify platen temperature and perform the "paper test" to check for even pressure.

Pre-pressing, as mentioned before, is crucial. It prepares the fabric by removing moisture and wrinkles, ensuring a smooth surface. After pressing direct-to-film transfers, allow garments to rest for at least 24 hours before washing. This period allows the adhesive to cure completely and bond strongly to the fabric.

Proper storage of your unused dtf sheet supplies and powders is also key. Store them in a cool, dry environment, shielded from high humidity, which can compromise their effectiveness. Adhere to the manufacturer's storage recommendations to maintain their peak performance for all your gang sheet transfers.

Design considerations also play a role. While DTF can handle fine details and small text, extremely thin lines might sometimes struggle with powder adhesion. Also, for a softer feel on large designs, consider breaking up large solid blocks of color or using patterns if the design allows. Understanding how a transfer size affects the feel can improve customer satisfaction.

Always test your process. If using a new brand of dtf transfers, a different fabric, or if you've altered your settings, perform a test print on a scrap piece first. This small step can prevent significant material waste and frustration when you press dtf. Adjust your settings until you achieve that perfect application every time. Remember to place order for samples if trying a new dtf gang sheet printing service for your dtf gang sheet needs.

Caring for Your Awesome DTF Creations

You've created fantastic custom apparel using a dtf transfer sheet or a custom dtf gang sheet. To maintain its great look through many washes, follow some simple care instructions. Proper care significantly extends the life and vibrancy of your DTF print.

Always turn the garment inside out before laundering. Wash it in cold or lukewarm water using a mild detergent. Steer clear of bleach, optical brighteners, and harsh chemicals, including fabric softeners, as these can damage the dtf transfers printed on the fabric over time. For basic fabric care, resources like Cotton Incorporated's guide offer useful tips for cotton items.

For drying, air drying is the gentlest method and highly recommended. If using a machine dryer, select a low heat setting or tumble dry cool. High heat from dryers can, over repeated cycles, affect the print's adhesive and appearance. When it comes to ironing, never apply an iron directly onto the DTF print. Iron the garment inside out on a low setting, or place a pressing cloth over the design if ironing the exterior is unavoidable.

With these care practices, your high-quality dtf transfers will remain sharp and vibrant for a long time. This attention to detail after creation helps maintain the professional look of your dtf product. It means your customers or you can enjoy the items, from basic blank t-shirts to more complex decorated pieces, for longer.

Conclusion

The dtf transfer sheet has firmly established itself as a leading solution in custom printing. Its capacity to generate vibrant, full-color designs on diverse fabrics, combined with great durability and the no-weeding advantage, makes it an excellent option for both businesses and hobbyists. Whether you are creating complex graphics for blank apparel or straightforward logos on a gang sheet dtf, using a quality dtf transfer sheet, perhaps from dtf gang sheet printing services, allows you to realize your creative visions with outstanding outcomes.

From understanding the basics of a dtf sheet to mastering the application of a heat transfer gang sheet, the journey offers rewarding results. The versatility to print multiple designs on a single dtf gang sheet and the easy application process streamline production. As we've seen, DTF stands strong against other methods, offering a blend of quality, flexibility, and efficiency, making it a valuable asset in modern apparel and product decoration. So, if you're ready to enhance your printing projects, it's time to order today and experience the benefits firsthand with your next gang sheet.