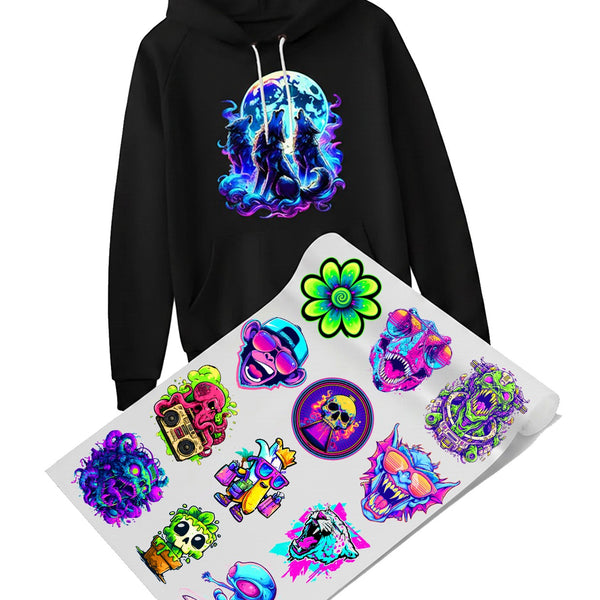

You've probably seen those incredibly cool t-shirts with vibrant, intricate designs. Ever wonder how they get those images looking so crisp and durable, especially on different colored fabrics? There's a strong chance you're observing the results of dtf printing. This method has been significantly impacting the custom apparel industry, and for very good reasons.

If you're curious about what DTF printing involves, you are in the right place. You'll learn how this technology functions, what makes it distinct, and if it could be the ideal solution for your creative projects or DTf printing business ideas. We will explore everything from the fundamental process of creating a DTF transfer to how it compares against other printing techniques, helping you understand what a DTF transfer is.

So, what exactly is DTF printing?

DTF stands for Direct to Film. It's a newer technology in the garment decoration industry, but it's making a substantial impact. Imagine it as a way to create a high-quality, versatile heat transfer, often referred to as a DTF transfer or film transfer. Unlike some methods that print directly onto a garment, DTF printing prints designs onto a special DTF film first. This film, typically a PET (polyethylene terephthalate) film, acts as the carrier for your DTF printed design.

The DTF ink is applied, then a special adhesive powder is used. This powder is what helps the design stick to the fabric when heat and pressure from heat presses are applied. It's a multi-step process, but each stage is vital for that final, amazing look of the transfer DTF. The development of various DTF printers has opened doors for printing on a wider variety of materials than ever before with relative ease, simplifying DTF transfer printing.

The DTF Printing Process: Step-by-Step

Understanding the steps involved can help you appreciate why DTF printing, also known as DFT printing, offers such excellent results. It might sound a bit technical, but the process is fairly straightforward once broken down. This is the core of the DTF transfer how to.

Step 1: Design Creation

Everything begins with your artwork. You will create or prepare your design using graphic software, much like you would for other printing methods. The quality of your digital file directly impacts the quality of your final print, particularly for DTF logo printing. High-resolution images with clean lines truly stand out with DTF.

Step 2: Printing on PET Film

This is where a specialized DTF printer, sometimes called a film printer, comes into play. These printers' DTFs are loaded with specific DTF inks – usually cyan, magenta, yellow, black (CMYK), and importantly, white DTF ink. The design is printed in reverse onto the PET dtf film. The white ink layer is typically printed last (or first, depending on layering for the shirt) to serve as a base on dark fabrics, which is crucial for vibrant DTf color.

Step 3: Applying Adhesive Powder

While the ink is still wet on the film, a special hot-melt adhesive powder is generously applied. This powder adheres only to the inked areas of the DTF printing transfers. Any excess powder is then shaken off, often automatically in systems like a DTF station or manually for smaller setups. This powder application is a critical part of making DTF heat transfers.

Step 4: Curing the Powder

Next, the DTF film with the ink and powder goes through a curing process. This usually involves heating it in a curing oven or under a heat press in a non-contact way, sometimes called "hovering." The heat melts the adhesive powder, transforming it into a smooth, even layer over the ink. The DTF film now holds a ready-to-apply DTF transfer.

Step 5: Heat Pressing onto the Fabric

Now it's time to prepare your garment for pressing dtf transfers. You place the cured film onto the fabric – be it a t-shirt dtf, hoodie, or tote bag. A heat press machine applies consistent heat and pressure for a set duration, which reactivates the adhesive, bonding the ink permanently to the fabric fibers. Careful pressing dtf is important for longevity.

Step 6: Peeling the Film (Hot Peel vs. Cold Peel)

After pressing, the PET film is peeled away, leaving your beautiful design on the garment. Depending on the type of film and adhesive powder used for your dtf transfers, this can be a "hot peel" (peeled immediately while hot) or a "cold peel" (peeled after it has cooled down). Both methods work well, but often result in slightly different finishes; for instance, cold peel sometimes offers a more matte finish to the dtf printed item. And there you have it – your custom dtf printing t-shirt is ready.

What Materials Can You Use with DTF Printing?

One of the biggest attractions of DTF, or dtf in printing, is its incredible versatility with fabrics. This provides a huge advantage over some other printing techniques. You are not as limited by material type or color when creating custom dtf heat transfers. DTF works beautifully on cotton, a staple for t-shirts, making dtf transfer on cotton very popular. But its capabilities extend further.

Polyesters, common in sportswear, take dtf printing on polyester exceptionally well. What about those popular cotton-poly blends? DTF handles them effectively. Even trickier fabrics like nylon, rayon, and leather can often be printed using DTF, though testing is always recommended for these specialty dtf applications. You can find information on material compatibility from resources like Printful's comparisons.

The ability to print vibrant designs on both light and dark-colored garments without much fuss is a significant benefit. That white ink base ensures your dtf color stays true and bright, no matter the background. Some people even experiment with dtf printing sticker applications on hard surfaces like wood or ceramics, though it's primarily designed for textiles. This also touches on the separate but related area of UV DTF printing for dtf sticker printing on non-textile items.

The Good and The Not-So-Good of DTF Printing

Like any technology, dtf printing has its strengths and areas where other methods might be preferred. Knowing these can help you decide if it's the right choice for your specific needs, especially if you are considering starting a dtf transfer business.

Advantages of DTF Printing

Let's discuss what makes DTF so attractive for dtf t-shirt printing and other applications.

- Versatility: As discussed, it works on a huge range of fabrics and colors, including dtf printing on polyester. This flexibility is a major plus for anyone wanting to offer diverse products.

- No Pre-treatment for Most Fabrics: Unlike Direct-to-Garment (DTG) printing, especially on dark fabrics, DTF generally doesn't require a pre-treatment liquid. This saves a step, time, and reduces the overall dtf printing cost.

- Vibrant Colors and Detail: DTF can produce sharp, bright, and detailed prints, including full color dtf transfers. Photos and intricate graphics, like those needed for dtf logo printing, look great.

- Good Durability and Stretch: When applied correctly, dtf transfers are quite durable and can withstand many washes. They also have a decent amount of stretch, good for apparel.

- Cost-Effective for Small to Medium Runs: For custom orders or smaller batches, DTF can be more economical than methods like screen printing, which have higher setup costs. This makes easy dtf printing accessible.

- Soft Hand (Often): While it can vary based on the powder and film used, many dtf prints, especially with newer consumables, can achieve a reasonably soft feel on the garment. Some people compare them to dtf screen prints in feel.

Disadvantages of DTF Printing

Now, for a balanced view, let's consider some potential downsides of dtf printing transfers.

- The Feel of the Transfer: Compared to DTG or dtf sublimation printing, the dtf transfer can sometimes feel more like a traditional heat transfer vinyl (HTV) on the shirt, especially with large, solid designs. It is an actual layer on top of the fabric.

- Equipment Investment: Setting up for in-house DTF printing requires specialized equipment: the dtf printer, dtf inks, dtf film, adhesive powder, a curing unit, and one or more heat presses. This can be a significant initial investment for a dtf printing business.

- Print Speed for Mass Production: For very large orders (hundreds or thousands of the same design), screen printing is still typically faster and more cost-effective per piece than printing dtf transfers individually.

- Environmental Concerns: The use of PET films (plastic) and powders raises some environmental questions about waste from the film transfer process. The industry is working on more sustainable options, but it's something to be aware of.

- Learning Curve: While not overly complex, there is still a learning curve to mastering the dtf transfer, how to use the process, and getting consistent, high-quality results. Understanding your printers for dtf is important.

DTF Printing vs. Other Popular Methods

So, how does dtf printing really compare to other ways you can get designs on fabric? It's helpful to see them side-by-side to understand where custom dtf printing fits. This helps in choosing the right printing services for your needs.

DTF vs. DTG (Direct to Garment)

DTG printers spray ink directly onto the fabric, much like an inkjet printer on paper. It's known for a very soft feel because the ink soaks into the fibers. However, DTG works best on 100% cotton and can struggle with polyester. It often requires pre-treatment for dark garments, adding time and cost. DTF, conversely, shines on various fabrics, including polys and blends, and generally skips pre-treatment, making dtf vinyl printing an alternative to consider too.

The feel of DTF might be slightly heavier than DTG, but its versatility in handling different materials and colors often wins out for many applications. Choosing between them depends on priorities like fabric type and desired hand-feel.

DTF vs. Screen Printing

Screen printing has been around for ages and is the standard for large volume orders. It uses stencils (screens) to apply layers of ink, producing very durable dtf screen prints (though technically screen prints are not DTF, some compare the look). It's cost-effective for big runs. However, screen printing dtf is not a direct comparison as screen printing has significant setup time and cost per color. It's not ideal for one-offs or designs with many colors or photographic detail.

DTF excels here, offering full color dtf transfers easily and with no per-color setup. This makes it superior for small, customized jobs.

DTF vs. Sublimation

Sublimation printing, often compared to dtf sublimation, creates incredibly vibrant, permanent prints with zero feel, as the ink becomes part of the fabric. Sounds perfect, doesn't it? The main limitation is that sublimation only works on polyester fabrics (or specially coated hard surfaces) and performs best on light colors. It doesn't use white ink, so it cannot print on dark polyester. DTF can print on almost any fabric, light or dark, making it much more versatile for general apparel needs like dtf printing t-shirts.

Garment decorators often compare dtf sublimation printing and DTF closely for sportswear due to polyester's prevalence in that market. DTF offers a solution for cotton and dark polyesters where sublimation falls short.

DTF vs. Vinyl (HTV)

Heat Transfer Vinyl (HTV), sometimes part of discussions on vinyl dtf, involves cutting designs from colored sheets of vinyl and then heat pressing them onto garments. It's excellent for simple text, numbers, or bold graphics. But, HTV can be time-consuming for intricate designs (weeding excess vinyl is tedious) and is limited to multi-color or photographic prints unless you layer, which can become bulky. DTF handles complex, full-color designs in a single application with a generally softer and more integrated feel than layered vinyl. The easy dtf application is a significant advantage.

Here's a quick table to sum up some key differences:

|

Feature |

DTF Printing |

DTG Printing |

Screen Printing |

Sublimation |

HTV (Vinyl) |

|

Fabric Versatility |

Very High (cotton, poly, blends, etc.) |

Mainly Cotton |

Most fabrics may need ink changes |

Polyester Only |

Most fabrics |

|

Dark Garments |

Excellent (with white ink base) |

Good (requires pre-treatment) |

Good (needs underbase) |

Not possible |

Good |

|

Feel (Hand) |

Light to Medium |

Very Soft |

Varies (can be heavy) |

No Feel |

Can be stiff/thick |

|

Color Capability |

Full color, gradients |

Full color, gradients |

Limited by screens (cost per color) |

Full color (on white/light poly) |

Limited by vinyl colors (layering needed) |

|

Small Runs / One-offs |

Excellent, cost-effective |

Excellent, cost-effective |

Not cost-effective (high setup) |

Excellent, cost-effective |

Good |

|

Durability |

Good to Very Good |

Good |

Excellent |

Excellent (permanent) |

Good |

This table should provide a clearer idea of where DTF fits. Considering these factors helps in deciding if ordering dtf transfers or investing in a system is the right path.

Getting Started with DTF Printing: What Do You Need?

If you're thinking about bringing dtf printing in-house for your dtf printing business, you'll need specific gear. It's more than just a film printer; it's a complete system. Here is a list of essential equipment and supplies for producing your own dtf heat transfers.

DTF Printer

This isn't your average office printer. A dedicated dtf printer is designed to handle PET dtf film and specialized dtf inks, including the crucial white dtf ink. Options range from smaller desktop models to larger industrial printers for dtf, like the Epson SureColor series modified for DTF, or systems from brands like Coldesi DTF, Station Prestige, or even the larger Station Prestige XL for high volume.

Specialized DTF Inks

You'll need CMYK and White dtf inks. These are formulated to work with the film and adhesive process, providing good dtf color vibrancy and adhesion. The quality of dtf inks significantly impacts the final print.

PET Film

These are specially coated dtf films, usually sold in rolls or sheets, that hold the ink and release it cleanly during the DTF transfer process. The film quality affects ease of peeling and the final texture.

Hot Melt Adhesive Powder

This fine powder is what makes the transfer dtf stick. It comes in different grades (e.g., fine, medium, coarse), some offering softer results or better stretch than others. The choice of powder can affect the hand-feel of the dtf printed garment.

Curing Oven or Shaker/Dryer Unit

You need a way to melt the powder evenly. For smaller setups, a heat press that can hover works, but for continuous production, an automatic powder shaker with an integrated curing tunnel is common, often part of a DTf Pro system or a DTf Station prestige setup.

Heat Press Machine

A quality heat press, or multiple heat presses, is vital for applying the final dtf transfer to the garment with consistent temperature and pressure. Proper pressing dtf transfers is crucial for durability.

RIP Software

Raster Image Processor software is very important. It helps manage print jobs, control ink levels (especially white for opacity and dtf color richness), optimize color accuracy, and can even help in creating a dtf gang sheet for printing multiple designs efficiently. Good RIP software helps manage dtf printing cost by minimizing ink waste.

Starter Bundles and Printing Services

You can often find starter bundles from suppliers. However, research each component's quality because it affects your final product. Many businesses also choose to start by ordering dtf transfers or custom dtf heat transfers from established printing services, skipping the initial equipment investment and focusing on design and sales. These services can often provide same-day dtf printing for urgent needs. Good customer service from your equipment and consumables supplier is also a valuable asset.

Gang Sheet for Efficient Production

For efficient production, especially when printing dtf transfers in volume, creating a dtf gang sheet is a common practice. This involves arranging multiple designs on a single large sheet of dtf film, optimizing material usage and printing time. These dtf gang sheets, or simply dtf gang, significantly reduce per-print costs. Some RIP software has features to help automate the creation of gang sheets.

A Note on UV DTF

A note on UV DTF: While this guide focuses on textile DTF, it's worth knowing that UV DTF printing is a related technology. UV DTF uses UV-curable inks to create dtf printing sticker designs that can be applied to hard, non-porous surfaces like glass, metal, and plastic, rather than fabrics. This is different from the dtf sticker printing for textiles discussed earlier, which uses standard DTF.

Is DTF Printing the Right Choice for You?

This is a significant question. The answer depends on what you want to achieve with your printing efforts. If you're a small business, a startup apparel brand, or someone who creates custom items, DTF offers amazing potential. It allows you to print vibrant, detailed designs, like dtf screen prints in appearance, on a huge variety of fabrics and colors without massive setup costs for each design. You can easily do small runs or even one-off custom dtf printing pieces.

Are you looking to print on materials that other methods struggle with, like dtf printing on polyester blends or nylon, without sacrificing dtf color vibrancy on darks? DTF could be your answer. It's great for testing new designs because you don't need to commit to large batches. A dtf transfer business can be quite profitable due to this flexibility. The ability to offer custom dtf heat transfers on demand is a strong selling point.

However, if you're producing thousands of identical shirts, screen printing might still be more efficient for you. If an ultra-soft feel on cotton is your absolute top priority for every single item, DTG might be worth a closer look, despite its limitations. Consider your budget, the types of products you want to make, your expected volume, and how much hands-on work you're prepared to do. Understanding the dtf printing cost per item, including consumables, is important for pricing. Technologies like printers for dtf transfers are powerful, but they require understanding their strengths and weaknesses to truly make them work for your dtf tshirt printing goals.

Conclusion

Direct to Film, or dtf printing, has certainly carved out a significant spot in custom decoration. Its ability to produce vibrant, durable dtf printed designs on a wide array of fabrics, both light and dark, makes it incredibly appealing for many applications, from t-shirt dtf to intricate dtf logo printing. While it involves a multi-step process and specific equipment like printers dtf, and heat presses, the results can be fantastic. This is particularly true for small to medium-sized businesses or anyone needing versatile, on-demand printing and easy dtf solutions.

The growth of dtf printing shows just how valuable this technology has become for creators and entrepreneurs looking to produce high-quality custom apparel and other items. Whether you invest in your own dtf station or start by ordering dtf transfers, the possibilities are extensive. Understanding dtf transfer printing can open up new avenues for your creative or commercial projects.