Ever wondered how long those awesome DTF prints can stick around? If you're new to Direct to Film printing or just curious about its staying power, you're in the right place. We're exploring DTF print durability, so you can feel confident about your next custom tee or trendy tote bag, especially when using a quality dtf transfer.

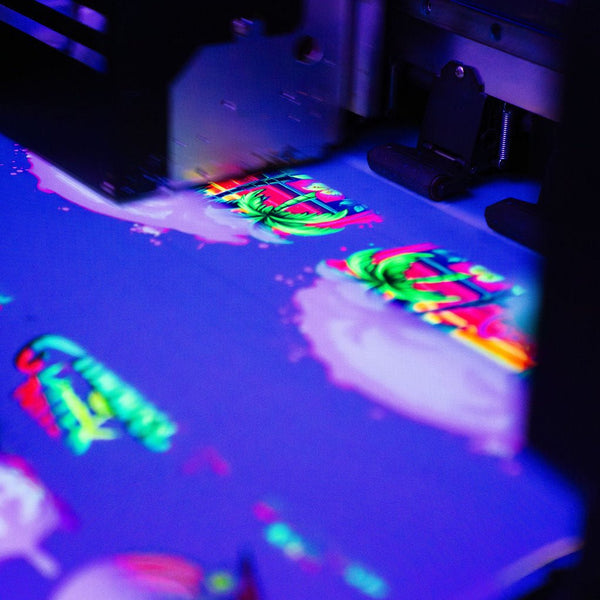

DTF printing has become a popular printing method in the custom apparel world. It's known for vibrant colors and the ability to print on almost any fabric type. But how does it hold up over a long time? Let's break down what makes dtf transfers durable.

What Affects DTF Print Durability?

Several factors affect durability of your DTF prints. From the quality of transfer materials used to how you care for your dtf printed items, it all matters. Here are some key factors including the printing method itself:

Quality of Materials

The foundation of a durable DTF print, a type of transfer print, starts with top-notch components. High-quality PET film (the transfer paper or, more accurately, transfer film), specialized pigment inks, and premium adhesive powders are crucial. These elements working together help your custom dtf design transfer smoothly and remain for the long haul.

Premium inks resist fading, keeping your designs bold and beautiful wash after wash. Good adhesive powder, available in different grades (fine, medium, coarse) depending on the fabric, creates a strong bond. This bond is what keeps the dtf print from peeling or cracking easily, contributing to a high-quality transfer.

Choosing quality materials for your dtf transfer printing projects is a critical first step. Some suppliers may even offer a free sample from their design library free sample collection, allowing you to test the quality firsthand before committing to a larger order of custom dtf transfers. This quality is essential for producing dtf transfers t-shirt designs that last.

Heat Press Settings

Getting the heat press machine settings just right is vital. Temperature, pressure, and press time must be precise for the printing method to succeed. Too cool, and the adhesive won't melt and bond properly with the fabric; too hot, and you might damage the fabric or the dtf transfer itself.

The ideal heat setting typically ranges from 300-320°F (150-160°C) for about 10-15 seconds, but this can vary depending on the specific dtf transfer materials and the fabric type. Correct pressure from the press machine is also important; too little pressure results in poor adhesion, while too much can push the ink too deep, affecting the vibrancy and feel. Even heat distribution across the platen of your heat press machine is fundamental for consistent results with your dtf prints.

The peeling method (hot, warm, or cold peel) also plays a role and is determined by the type of PET film used for the dtf transfer. Following the manufacturer's instructions for heat setting and peeling will create a solid bond, setting you up for long-lasting dtf prints.

Fabric Choice

Not all fabrics are created equal when it comes to dtf printing. Natural fibers like cotton, and even some polyester blends, tend to work very well with dtf transfers. They offer strong adhesion and allow the vibrant colors of the dtf print to truly stand out.

DTF printing is versatile and can be applied to a wide range of materials, including cotton, polyester, nylon, leather, and more. However, the interaction between the dtf transfer and the fabric type can affect durability. For example, highly elastic fabrics might test the limits of the print's flexibility over time, though quality dtf prints are known for good stretchability.

Synthetic materials sometimes present challenges for any printing method, but DTF is generally quite adaptable. With the correct transfer materials and heat press settings, dtf printing can achieve excellent results on most fabric types, making it a go-to for custom apparel. When creating transfers t-shirt designs, consider the fabric's composition for best results.

Post-Press Care

What happens immediately after pressing the dtf transfer matters too. Allowing the freshly printed item to cool down completely before its first wash or strenuous use is important. This cooling period allows the adhesive to fully set and cure, solidifying the bond between the dtf print and the fabric fibers.

Some professionals recommend a final, short post-press (usually for 2-5 seconds) with a protective sheet after the film is peeled. This can help to further embed the dtf print into the fabric, improving the feel and potentially adding to its resilience against wear and tear. This extra step in the printing method can contribute to how dtf transfers durable characteristics are enhanced.

How Many Washes Can DTF Prints Handle?

Now for the significant question: how many trips through the laundry can your dtf prints survive? The good news is, quite a few. High-quality dtf prints are known to be extremely durable. These printed items often undergo standard washing tests.

A quality dtf print can typically withstand 50 to 100 wash cycles without significant fading, cracking, or peeling. This level of durability often surpasses other digital printing methods like Direct-to-Garment (DTG) printing, especially on darker fabrics, and is comparable to traditional screen printing in many cases. This makes dtf printing an excellent choice for custom printing projects requiring longevity.

Of course, this range is an estimate and the actual number can vary depending on several factors. The specific quality of the dtf transfer materials, the precision of the heat press application, the fabric type, and how diligently care instructions are followed all influence the lifespan of the dtf printed items. Following proper care can help maximize durability.

Washing Tips for DTF Printed Items

Want to keep your dtf prints looking fresh for as long as possible? Following these proper care instructions is critical for your custom apparel:

- Turn garments inside out before washing. This minimizes friction on the dtf print surface during the wash cycle.

- Use cold water. Hot water can cause colors to bleed or fade over time and may weaken the adhesive of the dtf transfer. Washing in cold water is gentler on both the fabric and the print.

- Avoid harsh chemicals and bleach. These can break down the inks and adhesives in the dtf print, leading to premature deterioration. Opt for a mild detergent.

- Select a gentle wash cycle on your washing machine. A slower agitation and spin cycle are less aggressive on the dtf printed design.

- Do not use fabric softeners. These products often contain chemicals that can degrade the adhesive bond of the dtf transfer, causing it to peel or crack.

- If using a dryer, opt for a low heat setting or, even better, air dry your dtf printed items. High heat from dry cycles can damage the print and the fabric over time. Allowing items to air dry is the safest option.

Following these simple steps for your printed items can help your dtf prints stay vibrant and intact for a long time. It's all about treating your custom dtf gear with a little extra attention. These care instructions help make your dtf transfers durable.

DTF vs Other Printing Methods: A Durability Showdown

Curious how DTF printing stacks up against other popular transfer printing methods in terms of making transfers durable? Let's compare dtf with options like DTG printing, heat transfer vinyl (HTV), and traditional screen printing.

|

Feature |

DTF (Direct to Film) |

DTG (Direct to Garment) |

HTV (Heat Transfer Vinyl) |

Screen Printing |

|

Wash Durability |

50-100 washes (high-quality transfer) |

30-40 washes (can vary greatly with pre-treatment and fabric) |

40-50 washes (good quality transfer vinyl) |

50+ washes (plastisol inks are extremely durable) |

|

Stretch Resistance |

High, very flexible |

Moderate, can crack if overstretched, especially on darks |

Good, but some types of heat transfer vinyl can be stiff |

Moderate, plastisol transfers can be thick and prone to cracking if stretched excessively without proper additives |

|

Weather Resistance |

High, good against elements |

Moderate, water-based inks can be susceptible without proper curing |

High, vinyl is generally water-resistant |

High, especially with specialized inks |

|

Abrasion Resistance |

High, print integrates well |

Low to Moderate, ink sits on surface for darks |

Moderate, vinyl layer can scuff or peel with abrasion |

High, ink penetrates and bonds strongly |

|

Feel on Fabric |

Soft and flexible, can be slightly more noticeable than DTG on lights |

Very soft, especially on light garments where ink dyes fibers |

Can feel like a layer on top, varies with vinyl type |

Can range from soft (water-based) to thick (plastisol), potentially affecting pattern quality perception |

As you can see, DTF printing holds its own impressively well in the durability department for custom printing. It offers an excellent balance of wash resistance, flexibility, overall toughness, and vibrant color reproduction across various fabric types, including cotton and polyester blends. The dtf transfer printing process makes it a strong contender against methods like screen printing and transfer vinyl for many applications.

The Science Behind DTF Print Durability

Ever wondered what makes dtf prints so resilient? The durability of a dtf transfer is rooted in its unique printing method and the chemistry of its components. The process involves printing a design with specialized water-based pigment inks onto a PET film, then applying a thermoplastic polyurethane (TPU) adhesive powder to the wet ink.

When heat and pressure are applied using a heat press machine, this adhesive powder melts and acts as a binder. It bonds the pigment ink layer to the fibers of the fabric, creating a strong, yet flexible, cohesive layer. Unlike some printing methods where the ink merely sits on top, the dtf print becomes partially integrated with the fabric itself, almost like plastisol transfers but with more versatility for intricate designs.

This strong mechanical and chemical bond is what gives dtf prints their impressive staying power and resistance to cracking or peeling during standard washing. The pigment inks used in dtf printing are also formulated for excellent color fastness and UV resistance, helping to maintain their vibrant colors even after many dry cycles and exposure to sunlight. The overall pattern quality achieved with dtf is also a testament to this advanced printing method.

Real-World DTF Durability: What Users Say

Numbers and science are informative, but what about real-world experiences with this printing method? We gathered feedback from individuals and businesses that rely on dtf printing for their custom apparel needs.

Sarah, a small business owner specializing in custom dtf transfer orders, reported: "I've been selling dtf printed tees for over a year now. My customers rave about them because the designs, often sourced from our design library or from their upload gang sheet orders, stay bright even after months of wear and frequent washing. The dtf transfers t-shirt designs are a hit."

Mike, a sports team coach, shared: "Our team uniforms featuring dtf prints have held up amazingly well through a tough season. Even after numerous games, practices, and consequent washes, the custom printing looks almost new. The durability is fantastic compared to some heat transfer vinyl we've used previously."

Another user, a parent creating custom apparel for children, noted: "Kids are tough on clothes, but the dtf printed items I've made have survived countless playground adventures and spills. The vibrant colors remain, and the dtf print doesn't peel, which is crucial for active kids." These real-life examples show that dtf print durability, from a quality dtf source, isn't just a claim – it's a practical benefit for many users of dtf printed items for a long time.

Maximizing DTF Print Lifespan

Want to get the most out of your dtf prints and make those dtf transfers durable for as long as possible? Here are some additional tips to maximize durability and preserve your favorite dtf printed items:

- Store printed items properly. Fold them neatly or hang them in a cool, dry place away from direct sunlight when not in use. Prolonged exposure to UV light can eventually cause some fading in any printed garment.

- Avoid ironing directly on the dtf printed area. If ironing is necessary, turn the garment inside out and use a low heat setting, or place a cloth over the design.

- For items that don't require frequent washing, like decorative pieces or occasional wear garments, consider spot cleaning minor stains when possible. This reduces the number of full wash cycles the dtf print endures.

- Use a mild detergent specifically formulated for colored or delicate fabrics. These detergents are generally gentler on inks and adhesives, helping to maintain the integrity of the dtf transfer.

- Be mindful of abrasion. While dtf prints are quite resistant, constant rubbing against rough surfaces (like a coarse backpack strap or a seatbelt on every drive) can eventually wear down any print.

- When ordering custom dtf transfers, ask your provider about their specific materials and recommended care. Some advanced transfer materials might offer even greater resilience.

Remember, a little preventative care goes a long way. Taking these steps contributes to the longevity of your dtf prints, keeping your custom apparel looking great.

Understanding UV DTF vs. Textile DTF

It's worth noting a distinction in the "DTF" family: UV DTF and traditional textile DTF. While both involve a transfer printing process, their applications and durability characteristics differ. Textile DTF, the focus of this article, uses water-based inks and a heat-activated powder adhesive for application onto fabrics, resulting in a washable, wearable dtf print.

UV DTF, on the other hand, uses UV-curable inks and a different type of adhesive system. These transfers are designed for hard, non-porous surfaces like glass, metal, plastic, and wood. UV DTF prints are known for their excellent adhesion and scratch resistance on these substrates, but they are not intended for textiles and lack the flexibility and washability required for custom apparel.

So, when discussing dtf print durability for clothing and fabric items, we are referring to the textile dtf printing method. This ensures clarity and helps manage expectations for your custom printing projects, whether it's for dtf transfers t-shirt designs or other fabric-based dtf printed items.

The Future of DTF Print Durability

As technology in the printing industry continues to advance, so does the potential for even more durable dtf prints. Researchers and manufacturers are constantly working on improving ink formulations, adhesive powders, and the PET films used in the dtf transfer printing process. This ongoing innovation means the factors affect durability are always being refined for the better.

Some exciting developments on the horizon that could enhance how dtf transfers durable characteristics are perceived include:

- Nano-particle inks: These could offer deeper fiber penetration and enhanced color retention, making vibrant colors last even longer through numerous dry cycles and standard washing.

- Eco-friendly adhesives: Development is focusing on stronger, more flexible, and environmentally sound adhesives that offer even better bonding to a wider range of fabric types, including challenging polyester blends.

- Improved film technology: Advances in PET films might lead to easier peeling, more consistent transfers, and better overall pattern quality in the final dtf print.

- Integration with smart fabrics: Future textiles might be developed to work synergistically with dtf prints, enhancing both durability and functionality of dtf printed items.

These innovations aim to push the limits of dtf print durability further. This makes your custom dtf investments last longer than ever before, solidifying dtf printing as a leading printing method for custom apparel and other textile applications. For those looking to upload gang sheets or browse a design library, many providers who offer a login / system and a clear cookie policy are at the forefront of adopting these new technologies.

Troubleshooting Common DTF Durability Issues

Even with a robust printing method like DTF, issues can occasionally arise. Understanding common problems and their causes can help maintain the quality transfer and longevity of your dtf printed items. Here are some factors affect durability and how to address them:

Peeling Edges

This is often due to insufficient heat or pressure during the heat press application. It could also indicate a poor-quality adhesive powder or an incompatible fabric type. Revisiting your heat press machine settings and ensuring even pressure can often solve this. Also, ensure the dtf transfer materials are fresh and properly stored.

Cracking

While quality dtf prints are flexible, cracking can occur if the ink or adhesive layer wasn't properly cured, or if the fabric is overstretched beyond the print's capacity. Using high-quality, elastic inks and powders, along with correct curing (heat setting), helps prevent this. Proper care, like avoiding extreme stretching, also plays a part.

Fading

Premature fading can be caused by poor ink quality, excessive UV exposure, or the use of harsh detergents and hot water during washing. Always opt for high-quality pigment inks designed for DTF, wash in cold water with a mild detergent, and air dry when possible to keep vibrant colors bright. Storing dtf printed items away from direct sunlight also helps.

Addressing these factors proactively and following recommended guidelines for application and care will help make your dtf transfers durable and long-lasting. Many suppliers also offer support and free sample options to test their products, helping you achieve the best results for your dtf transfer projects.

Conclusion

DTF print durability is a significant advantage, making it a compelling choice for custom apparel and various textile products. With the ability to typically withstand 50-100 washes while maintaining vibrant color and structural integrity, dtf prints offer lasting value. This resilience makes the printing method ideal for businesses and individuals looking for high-quality transfer results.

By understanding the factors that affect durability, such as quality materials, precise heat press settings, appropriate fabric choice, and diligent post-press care instructions, you can significantly extend the life of your dtf printed items. Whether you are creating custom dtf transfers t-shirt designs, promotional gear, or personalized gifts, you can trust in the staying power of a well-executed dtf transfer printing job. For those looking to purchase, carefully review your selections in the cart before checkout; sometimes services offer access to a design library free sample to test.

So go ahead, create and wear your custom dtf print with confidence. It's designed to last, reflecting your style for a long time. Sharing your creations on platforms like Facebook Instagram can also inspire others to explore this durable custom printing option.