Have you heard people talking about a new way to put amazing designs on clothes? They are probably talking about DTF heat transfers. These innovative transfers are changing how people create custom apparel, and today you'll learn all about DTF heat transfers and why they might be perfect for your next project.

What Exactly Are DTF Heat Transfers?

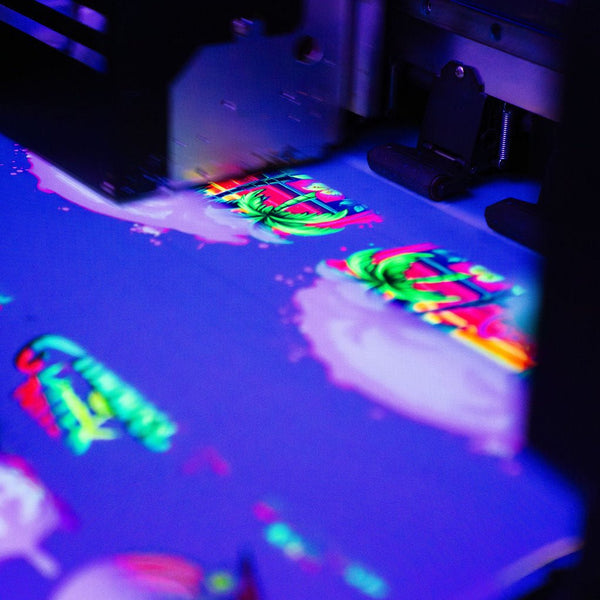

So, what's the big deal with DTF heat transfers? DTF stands for Direct to Film. This tells you a lot about the process right away.

Unlike some other methods, your design gets printed onto a special kind of clear transfer film first, often referred to as transfer sheets. Then, that printed film, carrying the dtf transfer, is used to transfer the design onto fabric with heat and pressure from a heat press.

This technique is a fantastic option for getting vibrant dtf, detailed images onto many types of clothing and accessories like tote bags or long sleeve shirts. It's making waves because it combines great quality with a fairly simple application to apply dtf designs, leveraging advanced ink technology for brilliant color transfers.

How Do DTF Heat Transfers Work? The Step-by-Step Process

Understanding how these film transfers come to life can help you appreciate their quality. It's a multi-step process, but each stage is important for the final dtf heat transfer result. Let's walk through it.

Essential Artwork Preparation

Everything starts with your artwork, the foundation of any great custom dtf project. You'll want a high-quality digital design, often created using graphic software or an online designer. Think about using software that lets you create crisp lines and vibrant ink colors for your perfect design.

Most people use file types like PNG, especially because they can have a transparent background which is ideal for a dtf heat transfer. This means only your design prints, not a big unwanted box around it. Using clip art judiciously can also enhance your designs before they are arranged on dtf gang sheets.

If you plan to combine multiple designs on one sheet, a gang sheet builder or a sheet builder tool can be invaluable. Some platforms even offer AI assist features to help refine or generate design elements, speeding up the creation of designs ready for printing. You may need to cut designs apart after printing if they are on a larger transfer sheet.

Printing on the DTF Film

This is where the "Direct to Film" part happens for your dtf transfers. You need a special printer made for dtf printing. These printers use specific DTF inks, usually in cyan, magenta, yellow, black (CMYK), and very importantly, white.

The printer first lays down the colored inks for your design. Then, it prints a layer of white ink on top. This white layer is crucial because it makes your colors pop, especially when applying the dtf heat transfer to dark blank apparel.

The quality of the transfer film itself is also important for achieving a clean release and durable printed transfers. This sophisticated ink technology allows for remarkable detail and vibrancy in each dtf transfer.

Applying the Adhesive Powder

Once the design is printed on the film and the ink is still wet, it's time for the adhesive powder. This is a fine, hot-melt powder. Its job is to act like a glue, helping the custom dtf transfers bond with the fabric later on during the heat pressing stage.

The powdered film is usually shaken to spread the powder evenly over the wet ink of the dtf transfer. Any extra powder that doesn't stick to the wet ink is then removed, often with a gentle shake or an air puff, leaving only the activated areas.

This step is fundamental for the durability and washability of the final color transfers. Without a proper adhesive layer, the dtf heat transfer may not adhere correctly or last through washes.

Curing the Film

Next, the powdered transfer film goes through a curing process. This involves heating the film until the adhesive powder melts and forms a smooth, even layer over the ink. This step is critical for a good dtf transfer that is ready to apply.

You can use a special curing oven for this, or some people carefully hover their heat press over the film, being cautious not to overheat. The goal is to melt the powder completely without damaging the transfer sheets or the ink itself.

Proper curing prepares the dtf transfers for application and significantly impacts the final feel and resilience of the design on the garment. It's a key part of making transfers ready for pressing.

The Heat Press Application

Now for the exciting part: getting the design onto your shirt or bag, such as blank t-shirts or other wholesale apparel. First, it's a good idea to pre-press your garment. This removes moisture and wrinkles, helping to achieve a flat surface for optimal adhesion of the dtf heat transfer.

You carefully place the cured dtf film onto the garment, design side down. Then, it all goes into the heat press. Specific time, temperature, and pressure settings are used for the heat pressing process; these can vary based on the film transfers, powder, and fabric type.

Using quality heat presses is important for consistent results when you apply dtf designs. Precision in this step leads to a professional-looking and long-lasting custom dtf transfer.

Peeling the Film

After the heat press does its job, you take the garment out. The transfer film then needs to be peeled off. Most DTF transfers are "cold peel," meaning you let the dtf transfer cool down completely before removing the film, though some may be a hot peel type.

If all steps were done correctly, the film peels away cleanly from the printed transfers. Your vibrant dtf design, whether a single image or part of a dtf gang, is now beautifully transferred to the fabric.

The peeling process is the final confirmation of a successful dtf heat transfer application. A clean peel signifies that the ink and adhesive have bonded effectively to the garment.

Why Are So Many People Talking About DTF Heat Transfers? The Big Benefits

You might be wondering what makes dtf heat transfers stand out. There are quite a few reasons why they've become so popular for custom dtf projects. Their advantages really address many common needs in custom decoration of wholesale apparel and individual items.

Versatility with Fabrics

One of the biggest pluses is how well DTF works on different materials. You can use these transfers transfer (referring to the general utility) on cotton, polyester, and blends of the two. They even work on trickier fabrics like nylon and leather, making them suitable for items from tote bags to performance wear.

This flexibility means you are not limited in what items you can customize. From blank t-shirts to hoodies, bags to hats, and even long sleeve shirts, DTF handles a wide range of blank apparel. Furthermore, dtf transfers can be effective in preventing dye migration on polyester fabrics, keeping colors crisp.

Vibrant Colors and Detail

DTF printing is fantastic for designs with many ink colors or intricate details, producing truly stunning color transfers. Because it's a digital printing process, you can get full-color graphics, gradients, and very fine lines. The white ink base really helps those colors show up bright and bold, creating vibrant dtf results even on dark garments, often surpassing standard screen printed transfers in brightness for complex images.

This opens up a lot of creative possibilities for your custom dtf transfers. You're not stuck with just a few solid colors like you might be with simpler screen printed methods.

Durability and Washability

When applied correctly, dtf heat transfers are surprisingly durable. They can withstand many washes without cracking, peeling, or fading quickly. This is important because nobody wants a design that disappears after a few trips through the laundry.

Following proper care instructions, like washing inside out, will help them last even longer. Customers appreciate this longevity, a hallmark of quality dtf transfers.

Soft Feel (Hand)

How a design feels on a shirt is a big deal. Many dtf transfers have a relatively soft feel, often much softer than some older types of heat transfer vinyl, especially for large designs. They tend to stretch with the fabric a bit, which adds to the comfort when applied to blank t-shirts.

This improved feel makes the decorated garment more pleasant to wear. This is a point many people notice and appreciate about custom dtf transfers compared to some thicker printed transfers.

No Weeding or Layering Complex Designs

If you have ever worked with heat transfer vinyl (HTV), you know that weeding can take a lot of time, especially for detailed custom dtf style designs. Weeding is the process of removing the unwanted vinyl parts from your design. With DTF, there is no weeding involved at all, saving valuable time in a business day.

Also, for multi-color designs, HTV requires layering multiple pieces of vinyl. DTF prints all the ink colors at once, making complex graphics and dtf gang sheets much simpler to apply dtf.

Cost-Effectiveness for Small to Medium Runs

For small businesses or individuals, dtf printing can be very cost-effective. Unlike screen printing, which often has high setup costs for multiple colors, DTF doesn't need new screens for each color. This makes it great for producing small batches or even single image custom dtf transfers without a high minimum order requirement from many suppliers.

It offers a professional result without the high upfront investment needed for some other methods, and you can often find competitive wholesale prices or even a sale price for dtf gang orders. This accessibility is a huge draw for those starting out or needing flexibility in order volume for their dtf heat projects.

What Do You Need to Get Started with DTF Printing?

Thinking about making your own DTF heat transfers? It's good to know what equipment and supplies are involved. It can be a bit of an investment if you want to do everything in-house for your dtf printing needs.

The Essentials for In-House Production

If you decide to set up your own dtf printing station, here's a list of the core items you will need:

- A DTF Printer: These are specialized printers designed for DTF inks and transfer film. They are the heart of creating your custom dtf transfers.

- DTF Inks: You'll need cyan, magenta, yellow, black (CMYK), and white DTF inks. Quality inks are crucial for vibrant dtf results and good ink colors.

- DTF Film: This is the special coated PET film, also known as transfer sheets, your designs are printed on.

- DTF Adhesive Powder: The hot-melt powder that acts as the glue for the dtf transfer.

- A Curing Solution: This could be a small curing oven or a dedicated heat source to melt the powder. Some use their heat press carefully for this.

- A Heat Press: Essential for applying the cured dtf heat transfer to the garment. Many types of heat presses are available.

- RIP Software: Raster Image Processor software is highly recommended. It helps manage color accuracy, white ink layers, and ink density for the best printed transfers.

This setup requires space and some technical know-how. But, it gives you complete control over the production process of your dtf transfers.

Or, Just Order Custom DTF Transfers.

Maybe setting up a full dtf printing operation isn't for you. That's perfectly okay. Many businesses and hobbyists choose another route. You can easily order custom dtf transfers from specialized suppliers, some of whom operate similarly to services like Transfer Express but always check their specific offerings.

Companies exist that will take your digital designs ready and print the transfers ready for you. You then just receive the ready-to-press film transfers. All you need is a heat press to apply dtf them to your items like blank t-shirts or tote bags.

This is a fantastic option if you want the benefits of dtf transfers without the big equipment investment or learning curve. You can often order a single image or larger dtf gang sheets with multiple designs. Many suppliers offer a gang sheet builder or sheet builder tool on their website, allowing for easy sheet upload or gang sheet upload. Some suppliers may offer fast turnaround, sometimes within one business day, and potentially free shipping on certain orders. Look for clear pricing, sometimes by the square inch, and check if there's a minimum order. Some may even have an affiliate program or offer live chat for support. Before uploading, it's wise to review their privacy policy regarding your designs. Some online designer tools might have a close menu button once you're done with a specific function.

DTF Transfers vs. Other Popular Methods: What's the Difference?

It helps to see how dtf transfers stack up against other common ways to decorate apparel. Each method has its strengths. Knowing the differences helps you pick the best one for your specific needs when working with blank apparel.

Here's a comparison table:

|

Feature |

DTF Transfers |

HTV (Heat Transfer Vinyl) |

Screen Printing |

DTG (Direct to Garment) |

|

Fabric Versatility |

Excellent (Cotton, Poly, Blends, Nylon, Leather) |

Good (Mainly Cotton, Poly-Blends) |

Good (Varies by ink type) |

Best on Cotton; struggles with Polyester |

|

Color & Detail |

Full color, high detail, gradients (vibrant dtf) |

Limited by vinyl color; layering for multi-color |

Good detail; each color needs a screen |

Full color, high detail, gradients |

|

Feel (Hand) |

Soft, flexible |

Can be thicker, varies by type |

Can be soft (water-based) or thicker (plastisol) |

Very soft, part of fabric |

|

Durability |

Very good (50+ washes) |

Good, varies by type |

Excellent, very durable |

Good, especially on light garments |

|

Weeding Required |

No |

Yes, can be time-consuming |

No (screen prep instead) |

No |

|

Cost for Small Runs |

Cost-effective (no setup per color) |

Cost-effective |

High setup cost, less ideal |

Can be cost-effective |

|

Cost for Large Runs |

Moderate, can use dtf gang sheets |

Can be less economical |

Very cost-effective |

Moderate |

DTF vs. HTV (Heat Transfer Vinyl)

HTV is a popular choice, especially for simpler, one or two-color designs. With HTV, you cut designs from a sheet of colored vinyl using a cutter, weed away the excess, and then heat apply it using heat presses or even a Cricut Easy Press or similar easy press device. DTF heat transfers skip the cutting and weeding.

DTF excels with full-color, complex images, which are hard or impossible with HTV. HTV can sometimes feel thicker on the shirt, while dtf transfers can offer a softer feel. However, some specialty HTVs like glitter or flock offer textures DTF doesn't inherently have.

Fabric compatibility is wider with dtf printing. HTV generally works best on cotton and poly-blends, whereas DTF can handle a broader range of blank apparel.

DTF vs. Screen Printing

Screen printing, which can produce screen printed transfers or direct prints, is the go-to for large volume orders with limited ink colors. It's very durable and cost-effective at high quantities. But, screen printing involves making a separate screen for each color in your design, a process that can lead to higher setup costs for printed transfers with many hues.

This setup can be expensive and time-consuming for small runs or designs with many colors. DTF, being digital, has no such screen setup for its color transfers. This makes dtf transfers much better for small orders, one-offs, or highly detailed, multi-color prints without a high minimum order for setup.

The feel of screen printing can be very soft, especially with water-based inks, which dtf heat transfers aim to match or improve upon depending on the transfer type.

DTF vs. DTG (Direct to Garment)

DTG printing is like using an inkjet printer directly on a shirt, typically blank t-shirts. It can produce beautiful, soft, full-color prints, especially on cotton. However, DTG printers are expensive and often require pre-treatment for the fabric, especially for dark garments where white ink is needed.

DTG doesn't work as well on polyester or many other synthetic fabrics, where issues like dye migration can be more prevalent. DTF heat transfers, on the other hand, work great on polyester and many other materials that DTG struggles with. The initial equipment investment for a dtf printing setup can also be lower than for a quality DTG setup.

Tips for Getting the Best Results with Your DTF Heat Transfers

Whether you are making your own dtf transfers or applying store-bought ones, a few tips can help you get professional results. Attention to detail makes a difference when working with any dtf heat transfer product. Here are some pointers.

Essential Artwork Preparation

Good output starts with good input, aiming for the perfect design. Make sure your digital designs are high resolution, ideally 300 DPI at the final print size. Using images with transparent backgrounds (like PNGs) is usually best to avoid printing a background box around your custom dtf artwork; some AI assist tools might help with background removal.

Clean, crisp artwork will always look better. This is true for any printing method, including dtf printing and creating film transfers.

Test Your Settings

Always do a test press if you are using a new type of dtf transfer or fabric, especially with different blank t-shirts or specialized wholesale apparel. The recommended time, temperature, and pressure for heat pressing can vary. Small adjustments might be needed to get the perfect application of your dtf heat transfers.

Too little heat or pressure, and the dtf transfer might not stick well. Too much, and you could damage the fabric or the color transfers.

Proper Curing Matters (If Making Your Own)

If you are producing your own custom dtf transfers, correctly curing the adhesive powder is vital. Undercured powder won't bond well during the dtf heat application. Overcured powder can lead to a stiff dtf transfer or issues with application, impacting the quality of your vibrant dtf design.

Follow the guidelines for your specific powder and curing equipment. Consistent curing leads to consistent quality in your printed transfers.

Storage of Transfers

If you have ready-to-press dtf transfers, such as those from dtf gang sheets or individual transfer sheets, store them properly. Keep them flat, in a cool, dry place. Avoid direct sunlight or high humidity, as these can affect the adhesive on the transfer film.

Good storage helps make sure they are in perfect condition when you are ready to use them. Laying them flat helps prevent creases in the film transfers.

Garment Care After Application

To make the beautiful dtf heat transfer design last, proper garment care is important. Advise washing the item inside out. Use cold or cool water and a mild detergent for any dtf transfers.

Tumble drying on low heat is usually okay, but hanging to dry can extend the life of the print even more. Avoid bleach and ironing directly on the custom dtf design.

Common Questions and Troubleshooting for DTF Heat Transfers

What if my DTF transfer isn't sticking completely?

This often points to issues with pressure, temperature, or time during the heat press step. Make sure your press is calibrated, try increasing pressure slightly, or check the recommended temperature for your specific DTF transfers. Also, always pre-press the garment to remove moisture, as this affects how the DTF heat is applied.

Why do my ink colors look dull or off on my custom DTF?

If you are printing your own DTF transfers, this could be related to your RIP software settings, ink quality, or even the curing process. If you are buying transfers ready from a supplier, talk to them. For applying, make sure your heat press temperature is accurate for the specific color transfers.

How long do DTF heat transfers last?

With proper application and care, good quality DTF transfers can last for many washes, often 50 or more. Their durability is comparable to well-applied screen printed transfers or even high-quality screen printed garments. The quality of the materials used (transfer film, ink, powder) plays a big part in the longevity of printed transfers.

Can I use a home iron or a Cricut Easy Press for DTF transfers?

While you might see some try, a proper heat press is strongly recommended for DTF heat transfers. Home irons and even devices like the Cricut Easy Press, though great for HTV and often called an easy press, don't typically provide the consistent, even pressure or accurate temperature control across the whole design needed for robust DTF transfer adhesion. This can lead to poor adhesion and durability issues with your custom DTF designs.

Is UV DTF the same as regular DTF?

No, UV DTF is a different technology, though it also uses a film. UV DTF transfers are typically designed for hard, non-porous surfaces like glass, metal, or plastic, not for blank apparel or textiles. They use UV-curable inks and often result in a sticker-like application with a raised feel, distinct from the textile-integrated DTF heat transfers used for clothing.

How are DTF gang sheets priced?

Pricing for DTF gang sheets or custom orders can vary by supplier. Some may price per square inch of the printed area on the transfer sheets, while others might have fixed prices for standard sheet sizes. Always check with your supplier for their specific pricing model and any potential sale price offers.

Conclusion

So, that's a good look at what makes DTF heat transfers a popular choice for custom decoration. They offer great ink colors, work on lots of fabrics like blank t-shirts and tote bags, and can handle some pretty complex designs from a single image to a full dtf gang sheet without a lot of fuss. If you are looking for a versatile and quality option for your projects, these dtf transfers are definitely worth checking out for your next custom dtf endeavor, whether you make them yourself or order transfers ready from a supplier providing fast turnaround.