Have you heard about the new wave in custom printing? It's called DTF, or Direct to Film. This method is making waves everywhere, and today we are looking at DTF Hampton Virginia. More people are choosing this for vibrant, durable designs on all sorts of items. So, if you are curious about DTF Hampton Virginia and what it can do for you, stick around.

Understanding DTF Printing - What's the Buzz About?

DTF printing has really changed the game for custom apparel and more. It offers a lot of flexibility and is a popular choice for many projects. People love it for many reasons, especially when they want quality DTF results.

The Basics: What Exactly is DTF?

DTF stands for Direct to Film. This technique involves printing your design onto a special film. Then, this printed film is transferred onto the fabric using heat and pressure for durable transfers.

Unlike some other methods, DTF often does not need pre-treatment for fabrics. This makes the process a bit simpler for many materials and is a key advantage when considering different printing solutions.

Think of it as an advanced version of a heat transfer. But, the overall quality and feel are usually much better with transfer printing. The technology allows for really bright colors and sharp details in the final dtf transfer.

Why DTF is Gaining Traction

One big reason DTF printing is popular is its versatility; it offers versatile printing solutions for many needs. It works on so many different types of fabrics. You can use it on cotton, polyester, and blends, making it a great option to choose dtf.

It even works on things like leather or nylon. The colors are another plus. They come out looking very vibrant and they last a long time; this is why many prefer color dtf methods.

This durability means your designs will not fade quickly after a few washes. Also, for small to medium print runs, DTF can be quite cost-effective. You do not have the same high setup costs you might find with methods like screen printing, which is good for small business budgets. This makes it great for businesses or individuals who do not need hundreds of items at once; they can simply bring designs and get started.

The DTF Printing Process Unpacked

The way DTF printing works is quite interesting. It involves several key steps for successful film printing. Each one is important for getting a great final product.

Step 1: Designing Your Artwork

Everything starts with a good design. Your artwork needs to be in a digital format. Many designers use software like Adobe Illustrator or CorelDRAW to create or prepare their files for custom dtf work.

For DTF, vector files are often preferred, but high-resolution raster images can work too. The printer will need a good quality file to get the best results. Common file types are .PNG, .AI, .EPS, or .SVG.

Make sure your design is exactly how you want it before sending it off for printing. This preparation helps achieve the best print quality.

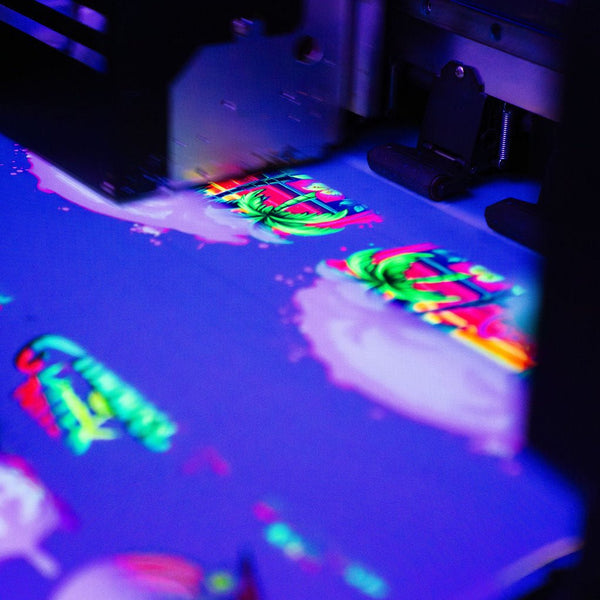

Step 2: Printing on the Film

Next, the design is printed onto a special PET film. This is not just any plastic film; it is made for DTF transfers. The printers used are also specialized, often utilizing advanced dtf printing techniques.

They often have multiple print heads for different colors, including white ink. White ink is important because it acts as a base layer, especially on dark fabrics. This helps the colors on top really pop, a hallmark of quality dtf.

The printer lays down the CMYK colors first, and then the white ink layer on top of that. Or sometimes, the white layer goes down first depending on the specific setup. The order is crucial for the dtf transfer process when using film virginia products or similar films.

Step 3: Applying the Powder

Once the design is printed on the film and the ink is still wet, it is time for the adhesive powder. This is a hot melt powder. It is a fine, granulated plastic material.

The film, with the wet ink, passes through this powder. The powder sticks only to the printed areas because the ink is tacky. Any excess powder is then shaken off; some systems do this automatically.

This powder is what will eventually bond the design to the fabric. It is a critical part of what makes dtf transfers stick so well and create durable transfers.

Step 4: Curing the Film

After the powder is applied, the film needs to be cured. This involves heating the film. The heat melts the adhesive powder and bonds it with the ink.

This creates a smooth, slightly rubbery layer on the film. Curing can be done using a heat press, a curing oven, or sometimes a specialized heated tunnel. The temperature and time for curing are important.

They must be just right to melt the powder properly without damaging the film or the ink. This step is vital for the integrity of the dtf virginia prints.

Step 5: Transferring to the Garment

Now for the exciting part: getting the design onto your item. The cured film, with the design and adhesive, is placed onto the garment. It goes exactly where you want the design to appear.

Then, a heat press is used. The heat press applies both heat and pressure for a specific amount of time. Typical settings might be around 300-325 degrees Fahrenheit for 10-15 seconds, but this can vary.

Settings depend on the film, powder, and fabric. Once the time is up, you open the press. Then you peel off the film; some films are "cold peel," others are "hot peel." Peeling reveals your design, now beautifully transferred to the fabric as a vibrant dtf transfer.

Benefits of Choosing DTF for Your Projects

DTF printing brings a lot to the table. Many people choose dtf because of its distinct advantages. Let's look at some of these benefits when considering printing services.

Amazing Detail and Color

DTF can reproduce very detailed images. This includes fine lines and small text. It also handles full-color graphics beautifully, including gradients and photographic images, offering excellent color dtf results.

The white ink underbase makes colors look rich and vibrant, even on dark colored shirts. This is a big step up from some older transfer methods. You can find examples of such detailed work through various textile printing examples online.

Works on Almost Anything

We touched on this before, but it is worth repeating. DTF's fabric compatibility is a huge plus, making it a versatile printing solution. Cotton, polyester, cotton/poly blends, spandex, nylon, leather, and even some hard surfaces can accept DTF transfers.

This opens up a lot of possibilities for custom products. You are not limited to just light-colored cotton t-shirts. This adaptability is something businesses really value, especially for promotional items and custom apparel.

Durability That Lasts

When done correctly, DTF prints are very durable. They hold up well to washing, resulting in durable transfers. They also have good stretchability.

This means the print can move with the fabric without cracking easily. This is important for items like sportswear or activewear. Of course, following care instructions helps make them last even longer.

Good for Small Batches

DTF is great for on-demand printing and small orders. Unlike screen printing, there are not high setup costs per design for dtf printing. You do not need to make separate screens for each color.

This makes it affordable to print just one item or a few dozen. It is perfect for custom gifts, small business merchandise, or test runs of new designs. This low barrier to entry helps many new brands start and bring designs to market quickly.

Softer Feel

The feel, or "hand," of a DTF print is generally quite soft. It is often softer than traditional vinyl heat transfers or some older plastisol transfers. While it is not as soft as dye-sublimation (which dyes the fabric fibers directly), it is a comfortable and wearable finish for custom apparel.

The exact feel can depend on the inks and powders used. Some are thinner than others, affecting the final print quality.

Finding DTF Hampton Virginia Services

So, you are interested in using DTF, perhaps specifically for DTF Hampton Virginia projects. How do you find a good provider? There are a few things to think about when looking for quality dtf printing services.

What to Look For in a DTF Provider

First, check their print quality. Ask to see samples of their work if possible. Look at the color vibrancy, detail, and the feel of the print.

Good providers are usually happy to show off what they can do with dtf transfers. Also, find out about their turnaround times. How long will it take to get your order? This is especially important if you have a deadline.

Pricing is always a factor. Get quotes and understand their pricing structure for custom dtf work. Are there minimum order quantities? Also, look for customer reviews or testimonials. What do other people say about their service and quality in the Hampton Roads area, including Newport News or Virginia Beach?

Finally, ask about their experience with different types of garments or materials if your project involves something unusual. Good printing solutions will accommodate various needs.

Local vs. Online DTF Services

You might wonder if you should use a local Hampton printer or an online service for your dtf virginia needs. Both have pros and cons. A local DTF Hampton Virginia provider lets you meet them in person.

You can discuss your project, see samples firsthand, and sometimes get faster local pickup. Supporting local businesses is also a plus for many people in the hampton roads community.

Online DTF services can offer a very wide selection. They might have very competitive pricing due to larger scale operations. Ordering is often convenient, done entirely from your computer.

But, you cannot physically inspect samples before ordering quite as easily. Shipping times and costs will also play a role. The best choice depends on your specific needs and preferences for dtf printing.

Questions to Ask a Potential DTF Hampton Virginia Printer

When you talk to a potential printer, have some questions ready. This helps you make an informed decision about their printing services. Consider asking these:

- What types of inks and powders do you use for dtf transfer? (This can affect quality and durability.)

- Can I see a sample of your work, perhaps on a similar fabric to mine, to assess the print quality?

- What is your typical turnaround time for an order of my size?

- Do you offer any design help or file checking services to bring designs to life?

- What are your artwork requirements (file types, resolution) for custom dtf?

- Do you have volume discounts for larger orders of dtf transfers?

- What are your care instructions for the finished DTF printed items?

- What happens if there is an issue with my order? (Their policy on reprints or fixes.)

Getting answers to these can give you confidence in your choice. It helps make sure your project using DTF Hampton Virginia services goes smoothly.

DTF Applications: More Than Just T-Shirts

While t-shirts are very popular for DTF, the possibilities go much further. This printing method is incredibly versatile, offering various printing solutions. You can use it for a huge range of items where quality dtf is desired.

Think about custom apparel beyond basic tees. Hoodies, sweatshirts, and tank tops are obvious choices. But also consider hats, beanies, and even socks. DTF can handle curved surfaces of caps with the right equipment, making custom dtf headwear feasible.

Tote bags and aprons are also great candidates for dtf printing. They offer a large canvas for designs. You might see these at farmers' markets or as promotional giveaways from a small business.

Promotional products for businesses are another big area. Companies can brand all sorts of items for events or employee gifts. Things like lanyards, small fabric pouches, or even mousepads can be decorated with DTF if the material is suitable, providing versatile printing solutions.

For individuals, personalized gifts become easy and memorable. Imagine a custom-designed pillowcase or a one-of-a-kind jacket for a friend, all created with durable transfers. Small businesses and startups particularly benefit from this accessible technology. They can create branded merchandise without huge upfront investment. This is great for Etsy sellers, bands, or local clubs needing custom apparel or items. Sports teams and school groups can get custom jerseys, warm-up gear, and spirit wear with excellent print quality. The durability of DTF is a good match for active use when you choose dtf. Essentially, if it is a fabric item that can withstand heat pressing, DTF is likely an option for transfer printing.

Exploring UV DTF Transfers: A New Frontier

Beyond fabrics, another exciting development is UV DTF. While standard DTF focuses on textiles, UV DTF transfers are made for hard, non-porous surfaces. This technology uses UV-curable inks printed onto a special adhesive film system.

The process typically involves printing the design (often with a white base and varnish layers for texture or protection) onto Film A. Then, Film B, a laminating sheet, is applied. To use the transfer, you peel Film B, apply the adhesive design to the object, press firmly, and then peel away Film A, leaving the cured ink design adhered to the surface. No heat press is needed for the application of uv dtf transfers.

This opens up amazing possibilities for customizing items like mugs, tumblers, phone cases, keychains, glass, metal, wood, and plastic products. UV DTF allows for vibrant, full-color, and highly durable designs on these challenging substrates. It is an excellent example of versatile printing that extends beyond apparel, offering robust printing solutions for promotional products and personalized gifts. For businesses in Hampton Roads looking to expand their offerings, exploring uv dtf can be a game-changer.

Caring for Your DTF Printed Items

To keep your DTF printed garments looking their best, a little care goes a long way. Following some simple guidelines will help maintain the vibrancy and longevity of the print, especially for durable transfers. Most providers of printing services will give you care instructions, but here are some general tips.

When washing, it is usually best to turn the garment inside out. This protects the print from abrasion with other clothes in the wash. Use cold or lukewarm water and a mild detergent for your custom apparel.

Avoid using bleach or strong fabric softeners, as these can degrade the dtf transfer over time. For drying, tumble drying on a low heat setting is generally okay for many DTF prints. However, hanging the item to air dry is even gentler and can extend the life of the print further.

If you do use a dryer, try to remove the garment promptly once it is dry. High heat is the main enemy of many types of prints, including those made with film printing techniques. If you need to iron the garment, do so inside out.

Use a low to medium heat setting on your iron. Never iron directly over the printed area on the outside. The heat from the iron can melt or damage the print. Following these simple steps will help your DTF items stay looking sharp for a long time, preserving the print quality.

The Future of Customization with DTF in Hampton Virginia

DTF printing is not just a fleeting trend; it is a significant step in how we customize products. Its accessibility is growing, making it easier for individuals and businesses in places like Hampton Virginia, Virginia Beach, and Newport News to get creative. This technology is empowering local creators and entrepreneurs within the hampton roads area.

They can now offer highly customized products without needing massive industrial setups. For anyone exploring options for DTF Hampton Virginia, the outlook is bright for various printing solutions, including those that involve film virginia supply chains.

This technology also has some interesting aspects regarding sustainability. Printing on demand, which DTF excels at, means less waste from overproduction; you only print what you need. Some argue DTF processes use less water compared to traditional dyeing or some screen printing methods.

As technology continues to improve, we can expect even more efficient and eco-friendlier DTF solutions. The ease of use and quality output mean we will likely see more innovative applications for DTF emerge in the future, helping people bring designs to life easily. This commitment to versatile printing will benefit many.

Conclusion

DTF printing offers incredible versatility, vibrant colors, and durable transfers for a wide array of fabrics and even hard surfaces with UV DTF. It is an excellent choice for businesses, creators, and anyone needing custom designs. Whether you are looking for a single item or a small batch for your brand, this technology delivers quality dtf results.

For those specifically considering DTF Hampton Virginia options, you will find a growing number of ways to bring your creative visions to life with this exciting print method. The ability to get detailed, full-color prints easily is truly transforming custom apparel and products here in Hampton Roads, from Virginia Beach to Newport News, as it is elsewhere. The future for DTF Hampton Virginia looks very promising indeed for all your custom dtf needs.