Have you ever wanted to put your designs on t-shirts, bags, or hats but found the process too complicated or expensive? Maybe you have a small business and need cool merch, but big order minimums just do not work for you. It is a common problem, but there is an excellent solution gaining popularity: custom dtf transfers. These transfers are changing the game for anyone looking to create personalized items; with custom dtf transfers, you can get vibrant, durable prints on all sorts of items without the old headaches. Many people start by searching for custom dtf transfers near me, hoping to find a local solution for their printing needs.

You are probably wondering what makes these transfers so special. Well, imagine getting full-color, detailed images onto fabric, and those images feel soft and last a long time. That is the kind of quality we are talking about. It is a very exciting option for creators everywhere who want to order custom dtf transfers.

So, What Are Custom DTF Transfers Anyway?

DTF stands for Direct-to-Film. It is a modern way to print designs that you can then press dtf onto fabrics using a heat press. Think of it like this: your design is first printed onto a special clear film, a type of film transfers technology.

Then, an adhesive powder is applied to the back of the print on the film. Once that powder is melted and cured, the design on the film is ready. You just place it on your garment, apply dtf heat with a heat press, and peel away the film, leaving your vivid, full-color design now part of the fabric.

This is different from other methods you might know, including some stock transfers or print transfers from the past. For instance, Direct-to-Garment (DTG) printing applies ink straight onto the clothing, which is effective, but sometimes struggles with dark polyester. Screen printing is excellent for bulk orders but has hefty setup costs, often including art fees for each color, especially for multiple colors or small batches. And vinyl cutting, while good for simple graphics using materials like adhesive vinyl, is not ideal for very detailed images or photos. Custom dtf transfers offer a sweet spot with lots of versatility.

The Magic Behind the Machine: How DTF Printing Happens

The process might sound a bit like tech wizardry, but it is fairly straightforward once you break it down. It involves a few key components working together to bring your designs to life. This method lets various dtf printers create high-quality images for you, resulting in impressive quality prints.

The Printer Itself

It all starts with a specialized DTF printer. These are not your everyday office printers; they are specifically built to handle special pigment inks and print onto specific PET (polyethylene terephthalate) films. DTF printers range in size from smaller desktop models suitable for hobbyists or small startups to large-format industrial machines for high-volume production. These printers can lay down a full-color image and, importantly, a layer of white ink.

The Special Inks

DTF uses water-based pigment inks. These inks are important because they offer great color vibrancy and durability, helping to create vibrant designs. The real star here is the white ink. It is laid down as a base layer under the colors, which allows your designs to look bright and bold, even on dark-colored fabrics. Without that white base, colors could look muddy or disappear on dark shirts.

The Transfer Film

The design is printed onto a clear PET film, often called DTF transfer film; these are specialized film transfers. This film is not just any plastic sheet. It is treated to hold the ink properly and then release it onto the garment during the heat press stage. It is usually a cold peel film, meaning you let it cool down before peeling it off the garment, which is different from uv dtf films used for stickers on hard surfaces.

The Adhesive Powder

After printing, the wet ink on the film gets coated with a special hot-melt adhesive powder. This powder sticks only to the printed ink. Any excess powder is shaken off, so only your design area has adhesive. This is a critical step, as this powder becomes the glue that bonds the print to the fabric.

Curing the Powder

Next, the film with the powdered ink goes through a curing process. This usually involves heating it in an oven or under a heat source. The heat melts the powder, turning it into a smooth, even adhesive layer on top of the ink. Once cured, the custom transfer designs can be stored as ready-to-press stock transfers or used right away, contributing to a fast turnaround for orders.

Pressing Time.

This is where your design finally meets the fabric. The DTF transfer film is placed onto the garment. Then, one of your heat presses applies even dtf heat and pressure for a set amount of time. The heat reactivates the adhesive and bonds the ink to the fabric fibers. After pressing, you let it cool (for cold peel films) and then carefully peel the film away, leaving your excellent print behind.

Why Choose Custom DTF Transfers for Your Projects?

You have choices for custom apparel, right? So why are so many people getting excited about these custom dtf transfers? There are some pretty solid reasons why they might be the perfect fit for what you are doing when considering dtf custom printing.

Vibrant, Full-Color Prints That Pop

One of the biggest advantages is the color. DTF transfers can handle incredibly detailed designs with a wide range of colors, helping to create vibrant and eye-catching graphics. We are talking photorealistic images, complex graphics, and smooth gradients. There are practically no color limitations, so your creativity does not have to be held back by screen setup costs or separate art fees for each color, which is common in screen printing.

Durability That Lasts Wash After Wash

You want your custom gear to look good for a long time, reflecting great quality. DTF prints are known for their excellent wash durability. When applied correctly, the design bonds strongly with the fabric and can withstand many wash cycles without cracking, peeling, or fading quickly, ensuring quality prints for the end-user. They also tend to have good stretchability, which means the print moves with the fabric rather than cracking under stress.

Works on Almost Any Fabric You Can Imagine

This is a huge plus for dtf transfers custom work. DTF transfers are super versatile with fabrics. They work great on cotton, polyester, cotton/poly blends, nylon, spandex, and even treated leather or canvas, making them ideal for a wide variety of blank apparel, including long sleeve shirts. Whether you are decorating light or dark-colored garments, DTF transfers deliver bright, opaque results. This opens up a lot more possibilities than some other printing methods that are more fabric-specific.

Great for Small Batches and One-Offs

If you are just starting out, need a few samples, or want to create truly personalized one-of-a-kind items, dtf custom is your friend. Unlike screen printing, there are no high setup fees for different designs or multiple colors. This makes custom dtf heat transfers very cost-effective for small orders or even single pieces. This is a game-changer for small businesses managing inventory and cash flow, especially when suppliers offer quick shipping, often within a business day.

A Surprisingly Soft Feel

Nobody wants a thick, plastic-feeling design on their comfy t-shirt. DTF transfers, especially after the first wash, tend to have a softer hand feel than older heat transfer vinyl methods or even some thicker sublimation transfers on certain materials. While it is not as undetectable as dye-sublimation (which only works effectively on polyester), it is a comfortable and professional finish. The ink bonds with the fibers rather than sitting heavily on top.

Intricate Designs? No Problem.

Got a design with tiny details, fine lines, or complex patterns? DTF can handle it. The printing process allows for sharp details and clear text, even in smaller sizes. This means you do not have to simplify your artwork as much as you might for other methods. You can really push the boundaries of your design work with custom dtf.

Getting Your Own Custom DTF Transfers

Alright, so you are convinced that custom dtf transfers sound beneficial. How do you actually get your hands on them and order custom dtf transfers? It is easier than you might think, but there are a few things to keep in mind to get the best results.

Nailing Your Artwork Design

Great transfers start with great artwork. To make your prints look professional, pay attention to these details. A little prep here goes a long way for your dtf custom transfers.

- File Types: Most DTF providers prefer high-resolution PNG files with a transparent background. Other formats like AI (Adobe Illustrator), PSD (Adobe Photoshop), or EPS might also be accepted. Always check with your specific supplier.

- Resolution Matters: For crisp, clear prints, your artwork should be at least 300 DPI (dots per inch) at the final print size. Using low-resolution images will result in blurry or pixelated prints, which nobody wants. You can learn more about image resolution for printing from various online resources.

- Transparent Backgrounds Are Essential: This is very important. Your design file must have a transparent background. If it has a white or colored box around it, that box will be printed along with your design. You only want the actual artwork to be printed.

- Think About Gang Sheets: If you have multiple small designs, ask your provider about using a dtf gang sheet. This means they arrange several of your designs onto one larger film sheet, effectively creating dtf gang sheets. This can be a very cost-effective way to get many transfers printed at once, maximizing the value of your custom dtf gang sheets. Many providers offer a gang sheet builder or sheet builder tool on their website to help you upload dtf gang sheet files efficiently. The ability to upload dtf gang layouts yourself often streamlines the ordering process.

Finding a Reliable DTF Transfer Provider

You will need to find a company that prints these custom dtf transfers for you. There are many out there, both local and online. When looking for custom dtf transfers near me or browsing online stores for dtf custom printing, consider these points. Finding a good partner makes all the difference.

- Quality is King: Look for samples of their work or customer reviews that speak to the print quality and durability, indicating great quality and consistent quality prints. Do not just go for the cheapest option; poor quality transfers will reflect badly on your products.

- Read Reviews: See what other customers are saying about their experience. Pay attention to comments about customer service, turnaround times, and print accuracy.

- Turnaround Time: How quickly do you need your transfers? Some suppliers offer a fast turnaround or rush order services, but this usually costs extra. Understand their standard production time, often quoted in business day terms, and check for any pm est cutoff times that might affect shipping.

- Customer Service: Good communication is important. You want a provider who is responsive to your questions and can help if issues arise with your dtf transfers custom order.

The Ordering Process Explained

Once you have chosen a provider, the ordering process for custom dtf is usually pretty simple. You will typically upload your prepared artwork files through their website. Then, you will specify the size you want each design printed and the quantity of transfers you need. Many providers will send you a digital proof or mock-up showing how your design will look as a transfer. Review this carefully before approving it to make sure everything is correct – colors, size, placement, and that the background is indeed transparent.

Applying Your DTF Transfers Like a Pro

Getting your transfers is half the fun; now it is time to bring your creations to life. Applying custom dtf heat transfers properly is critical for that professional look and lasting durability. Do not worry, it is not too tricky, but you do need the right tools and to follow the steps to press dtf transfer correctly.

What You'll Need on Hand

To get started, gather these items. Having them ready makes the process smooth when working with blank apparel and your new transfers.

- Heat Press: This is the most important tool. While some might wonder about using a home iron, it is really not recommended for DTF transfers. A heat press (or multiple heat presses for larger operations) gives you consistent, even temperature and pressure, which an iron just cannot do. This is vital for a good application.

- Parchment Paper or Teflon Sheet: You will use this over the transfer during pressing to protect your garment and your heat press platen.

- Your Garments: Have your t-shirts, hoodies, or other blank apparel items clean and ready.

- The DTF Transfers: Of course. Your freshly printed custom dtf transfers.

Getting Heat Press Settings Right

Correct temperature, pressure, and time settings are very important when you press dtf. These can vary slightly based on the specific transfers your supplier provides and the fabric you are using, as different materials react differently to dtf heat. Always check the instructions from your DTF transfer supplier first. But here are some general guidelines. Many providers give a settings guide with your order.

|

Fabric Type |

Temperature Range |

Time Range |

Pressure |

|

100% Cotton |

300-325°F (150-163°C) |

10-15 seconds |

Medium-Firm |

|

Polyester & Blends |

275-300°F (135-150°C) |

8-12 seconds |

Medium |

|

Tri-Blends / Delicate |

260-280°F (127-138°C) |

8-10 seconds |

Light-Medium |

Always test on a scrap piece of fabric if you are unsure. This can save you from ruining a good garment.

Step-by-Step Application Guide

Here is how you do it. Take your time and follow each step to press dtf transfer correctly.

- Pre-press Your Garment: Place your garment on the heat press and press it for 3-5 seconds. This removes moisture and wrinkles, giving you a flat, smooth surface for the transfer.

- Position Your Transfer: Carefully place the DTF transfer onto the garment, design side down (film side up). Make sure it is straight and exactly where you want it. You can use heat-resistant tape to hold it in place if needed.

- Press It: Cover the transfer with your parchment paper or Teflon sheet. Close the heat press using the recommended settings for temperature, time, and pressure for the specific custom dtf material.

- Peel the Film: This is an important step. Most DTF transfers are "cold peel." This means you must let the transfer and garment cool down completely before you try to peel off the film. Peeling too soon can ruin the transfer. Once cool, peel the film back slowly and smoothly at a low angle. Some transfers might be "warm peel," so again, check your supplier's instructions.

- Optional Second Press: For an even softer feel and to further embed the design into the fabric, many people do a quick second press. After peeling the film, cover the design again with parchment paper or a Teflon sheet and press for another 3-5 seconds. This can also improve durability.

Fixing Common Issues

Sometimes things do not go perfectly. Here are a couple of common hiccups and how to handle them when working with custom dtf printing results.

- Transfer Not Sticking: This could be due to insufficient pressure, temperature too low, or not enough time. Double-check your settings and make sure your press is applying even pressure. Also, make sure you are following the correct cold or warm peel procedure.

- Scorching or Shiny Marks: If your fabric is getting scorched or has shiny marks, your temperature might be too high, or you might be pressing for too long. Using a Teflon sheet or a thicker parchment paper can also help protect sensitive fabrics. Always test first.

Caring for Your Awesome DTF Decorated Items

You have put in the effort to create or apply these quality custom dtf transfers. Now, you want them to look great for as long as possible, right? Proper care is simple, but it makes a big difference in how long your designs stay vibrant and intact. Sharing these care instructions with your customers is also a good idea if you are selling your creations made with dtf custom transfers.

The good news is that DTF prints are quite durable. But a little TLC will go a long way. Here is what you need to know.

Think of these as guidelines to maximize the life of your printed garments. It is all about being gentle.

- Wait Before Washing: After applying a DTF transfer, it is best to wait at least 24-48 hours before the first wash. This gives the adhesive and ink more time to fully cure and bond with the fabric.

- Turn It Inside Out: This is a classic tip for any printed garment. Turning the item inside out before washing protects the print from abrasion with other clothes in the wash.

- Use Cold Water: Wash your DTF decorated items in cold or cool water. Hot water can stress the print and the fabric over time, potentially leading to faster fading or breakdown of the adhesive.

- Mild Detergent is Best: Use a gentle, mild detergent. Avoid harsh chemicals, bleach, or fabric softeners, as these can degrade the print quality. Fabric softener, in particular, can weaken the adhesive bond.

- Gentle Wash Cycle: If your washing machine has it, use a gentle or delicate wash cycle. This reduces the agitation and stress on the garment and the print.

- How to Dry: For the best longevity, hang drying your DTF printed items is ideal. If you must use a dryer, tumble dry on the lowest heat setting; avoid high dtf heat which can damage the print over time. High heat from a dryer is one of the main enemies of custom prints.

- Ironing, If You Must: Avoid ironing directly on the DTF print. If the garment is wrinkled, turn it inside out and iron on a low setting, or iron around the design. Direct high heat from an iron can melt or damage the print.

So, how long should your DTF prints last? With proper application and care like this, high-quality custom dtf transfers can last for 50+ washes, sometimes even more. They often last as long as the garment itself, maintaining good color and adhesion. They are built to be worn and enjoyed.

Super Cool Ideas for Using Custom DTF Transfers

Now that you know more about what custom dtf transfers are, how they work, and how to care for them, let's get to the fun part. What can you actually create with them? The possibilities are extensive, but here are a few ideas to get your creative juices flowing and develop your unique product style.

From personal projects to business branding, DTF is very flexible. You might be surprised at all the ways you can use dtf custom designs.

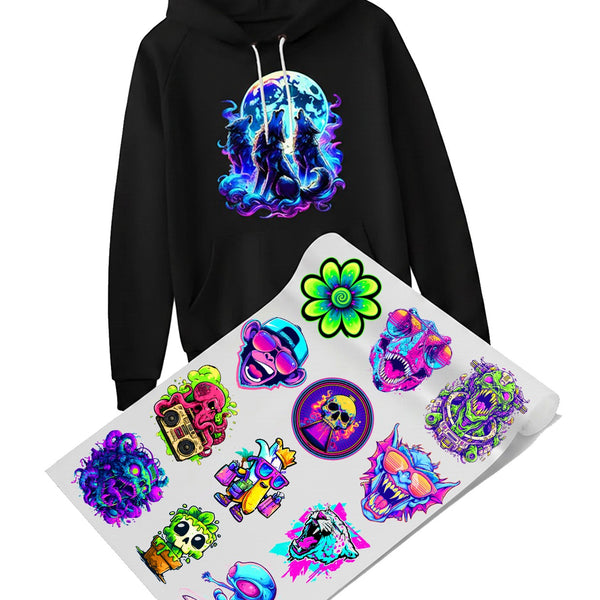

- Custom T-Shirts and Hoodies: This is probably the most popular use. Create tees, including long sleeve options, for your band, brand, family reunion, or just for fun. DTF excels at full-color graphics, photos, and detailed logos.

- Stylish Hats and Beanies: DTF transfers can be applied to various types of headwear, including baseball caps and beanies. This is great for branding or personal expression.

- Personalized Bags and Totes: Think canvas tote bags for shopping, gym bags, or custom backpacks. It is an easy way to make an everyday item stand out.

- Team Jerseys and Athletic Wear: Since DTF works well on polyester and performance fabrics, it is a good option for sports teams. Player names, numbers, and team logos can all be applied.

- Small Business Branding: Create uniforms for your staff, promotional items for giveaways, or branded merchandise to sell. DTF's cost-effectiveness for small runs through dtf custom printing services is perfect for this.

- Unique Personalized Gifts: Make someone feel special with a truly personalized gift, perhaps for Father's Day or a birthday. Think custom aprons for the family chef, pillowcases with a favorite photo, or jackets with a cool design.

- Event and Promotional Items: Got an event coming up? DTF transfers are great for making shirts for staff, volunteers, or as merch for attendees. They are quick to produce if you are working with a good supplier providing dtf transfers custom made.

- Kid's Clothing and Onesies: The soft feel and durability make DTF a solid choice for children's apparel. Imagine cute custom designs that can withstand active play.

- Home Decor and More: You can even use them on fabric items for home decor, like cushion covers or fabric wall hangings. For hard surfaces, you might explore uv dtf technology, which creates durable dtf stickers suitable for items like mugs or phone cases, though this is a different process than fabric DTF.

Basically, if you can get it relatively flat under a heat press, there is a good chance you can put a DTF transfer on it. This versatility is a big reason why custom dtf transfers are becoming so popular for all sorts of projects, big and small. Get creative and see what you can come up with.

Custom DTF Transfers vs. The Other Guys: A Quick Look

You have learned a lot about custom dtf transfers. But how do they stack up against other popular garment decoration methods like screen printing or using custom heat vinyls? It is good to know the pros and cons so you can choose the best technique for your specific needs when you order custom dtf transfers or consider alternatives. Each method has its strengths.

Let's put them side-by-side in a simple comparison. This will help you see where DTF really shines and when another option might be better. Understanding these differences can save you time and money.

|

Feature |

Custom DTF Transfers |

Screen Printing |

Direct-to-Garment (DTG) |

Heat Transfer Vinyl (HTV) |

|

Color Capability |

Full color, gradients, photos |

Limited by screens (each color needs a new screen) |

Full color, good for photos |

Usually solid colors; layering for multi-color. Options like siser glitter htv or siser holographic provide effects. |

|

Detail & Complexity |

Excellent for fine details |

Good, but very fine details can be tricky |

Good, can print fine details |

Best for simpler shapes; weeding complex designs from products like siser easyweed or specialty vinyls like siser easy puff can be tough. |

|

Durability |

Very good, 50+ washes |

Excellent, often outlasts garment |

Good, but can vary; pretreatment helps |

Good; quality varies from basic siser easy to more robust types, but some like siser sparkle or siser metal can eventually crack/peel. |

|

Hand Feel |

Soft, especially after washing |

Can be soft (water-based) or thicker (plastisol) |

Very soft, ink soaks into fabric |

Can be thicker, noticeable on garment. Some, like easy puff, have a distinct raised texture, while siser stripflock is velvety. Siser brick is very thick. |

|

Fabric Compatibility |

Very wide (cotton, poly, blends, darks, lights) |

Good for most fabrics, specific inks for some |

Best on 100% cotton, some issues with polyester |

Wide range; specific types for different fabrics, including siser easypsv for decals (not apparel) or siser easysubli for sublimating on cotton. Options like siser twinkle or easypsv glitter offer different looks. |

|

Cost for Small Runs |

Excellent, no setup fees per design |

High due to screen setup costs |

Good, no setup fees |

Good, depends on vinyl cost (e.g., siser glitter is more than plain) and complexity. Transfer tape may be an added cost/step for some HTV. |

|

Cost for Large Runs |

Good, but can be less economical than screen printing for very high volumes |

Excellent, very cost-effective for high volumes |

Can be more expensive per piece for large runs |

Can be labor-intensive for large runs if designs are complex |

|

Setup Effort |

Low (design prep, printing film for your custom dtf) |

High (screen creation, registration) |

Moderate (garment prep, pretreatment for darks) |

Moderate (design, cutting, weeding). Products like siser metal might need specific settings. |

So, when might you pick something else? If you need thousands of one-color shirts, screen printing is probably your most cost-effective bet. If you want the absolute softest print possible on a white cotton tee with a very complex, photographic design and are doing small quantities, DTG could be great. For very specific textured effects like a thick siser brick feel, or sparkly names and numbers where siser glitter htv or siser sparkle excel, HTV still has its place. You might also consider sublimation transfers for 100% white or light-colored polyester items where the ink becomes part of the fabric.

But for overall versatility, full-color capabilities on almost any fabric, great durability, and cost-effectiveness for small to medium runs, custom dtf transfers from a provider, whether you are searching dtf custom transfers near me or online, are quickly becoming a go-to for many people. They offer an excellent balance of features. This also applies to dtf custom printing services that handle the entire process for you.

Conclusion

Well, there you have it. We have covered a lot about custom dtf transfers. From understanding what they are and how they are made, to applying them and caring for your finished creations, you are now much more familiar with this effective technology. It is clear that custom dtf transfers are a powerful tool for anyone looking to make high-quality, personalized apparel and accessories without a lot of the old hassles or high costs for small batches.

The ability to order custom dtf transfers easily and print vibrant, full-color designs on a wide variety of fabrics, coupled with their impressive durability and soft feel, makes them a standout choice. Whether you are a small business owner needing branded merchandise from dtf custom printing services, a designer wanting to bring intricate artwork to life on clothing, or just someone who loves creating unique gifts, these transfers offer excellent possibilities. Think about how you could use custom dtf heat transfers for your next project.