All You Need to Know About Direct-to-Film (DTF) Printing

Do you say DTF printing? Yes! It is everywhere now; the to-film printing method has earned a great reputation in textile printing and beyond. Compared to all traditional printing methods, from screen printing to DTG printing, DTF has become the most cost-effective, durable, and versatile printing option.

From businesses to individual preferences, we see a surge in demand scale. If you are still unaware of its benefits, variety of customized items, and process, this guide is for you! Here, you can get complete information about this revolutionary printing method.

What is Direct-to-Film (DTF) Printing?

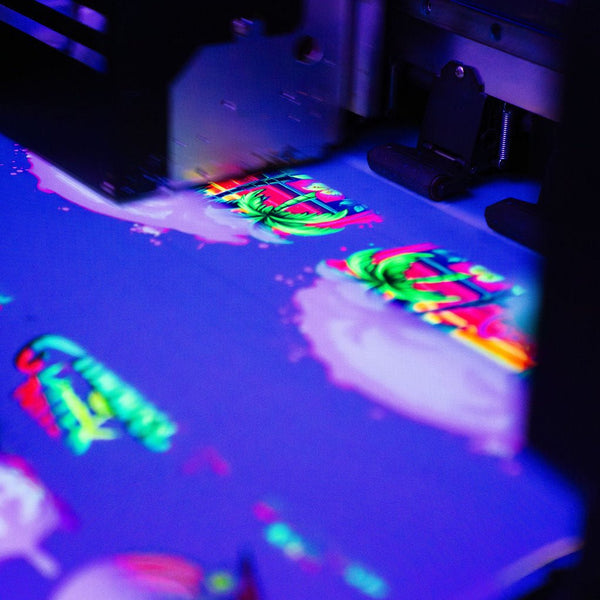

This advanced printing method uses a transfer film and specific inks. For those who ask which inks are used in DTF, basically, two main types of inks are commonly used for DTF printing: Eco-Solvent Inks and UV Curable Inks. Epson UltraChrome DG and Roland ECO-SOL MAX inks adhere well to transfer films and fabrics, making them suitable for DTF printing.

Another option is UV-curable inks, such as Mimaki LUS-170. UV light is used to cure the ink on the transfer film quickly. Heat and pressure are used to transfer the print from PET film to fabric. In terms of materials and quality, DTF printing offers greater flexibility.

Benefits of Direct-to-Film (DTF) Printing

DTF printing offers numerous amazing benefits to businesses and people. Here are the key benefits:

Versatile Option

Fabric printing with DTF is a versatile option since it is compatible with a variety of fabrics, such as cotton, polyester, and blends, nylon, silk, etc. This versatility makes it suitable for numerous fashion, home decor, and promotional merchandise applications. To order your favorite DTF print, click DTF Virginia.

Cost-Effectiveness Alternative

In the beginning, it is expensive to set up and run a business, but compared to the other method, no screens need to be created or extensive setup is required, which reduces the initial costs. It is much more cost-effective for small businesses, and it is much more profitable in the long run.

Moreover, DTF printing uses digital designs, which results in minimal waste of ink and materials. This can lead to significant savings over time.

High-Quality Prints

DTF is best for achieving vibrant colors and fine details because when high-resolution images with vibrant colors and sharp details are printed on the fabric or any material, it looks fabulous.

This makes it ideal for complex designs and artwork that require precision. If we talk about durability, it bears multiple washes without any damage. DTF prints are resistant to fading, cracking, and peeling, so the printed items remain in good condition for a long time.

Flexibility in Design

There are no color limitations because DTF printing allows an unlimited number of colors in a single design. This is particularly advantageous for designs that require a wide color gamut or gradients.

And just because the design is digital, you can easily customize it to meet specific customer requirements. This makes DTF printing perfect for personalized items and small batches.

Faster Production Times

With fewer setup steps and the ability to print directly from digital files, DTF printing offers faster turnaround times compared to traditional screen printing methods. This speed is essential for meeting tight deadlines.

Moreover, another benefit is that DTF printing supports on-demand production, which means businesses can print items as needed rather than maintain large inventories. Simply, there is more efficient inventory management and reduced storage costs.

What are Customized DTF Printing Items?

There are several customized DTF printed items according to the interest of the people. Here's a closer look at the types of items that can be customized using DTF printing:

Apparel

- You can get customized t-shirts with your favorite DTF print on them. There are endless unique designs that reflect the brand, message, or personal style.

- DTF printing works well on thicker fabrics like hoodies and sweatshirts with detailed graphics and vibrant colors.

- From baseball caps to beanies, DTF printing offers detailed and colorful designs on headwear. It is perfect for marketing or for gift purposes.

Bags and Accessories

- You can customize tote bags that are practical and stylish. DTF printing works best on fabric material, which makes it ideal for promotional events or personal use.

- Personalizing backpacks with DTF printing can turn a simple accessory into a unique and eye-catching item. It is perfect for schools, businesses, or personal use.

- Small accessories like pouches and wallets can also be customized with DTF printing.

Home Textiles

- Home textile items include cushion covers that you can add as a decorative piece with some great prints in your room. You can match them with any interior design theme or personal taste.

- Custom designs on tablecloths and napkins can add a special touch to dining experiences, whether for personal use or special events.

Promotional Items

- Personalized bandanas and scarves are popular promotional items that can be branded with your logo, slogan, or intricate design.

- DTF printing can produce detailed and durable designs on They are ideal for conferences, events, and corporate branding.

- Customized aprons are another option for culinary events, cooking classes, or as personalized gifts for cooking enthusiasts.

How to Apply DTF Print Transfers?

Here is a complete process to apply DTF print transfer:

Materials Needed

- DTF transfer film with printed design

- Fabric or garment to be printed

- Heat press machine

- Teflon sheet or parchment paper

- Lint roller

- Heat-resistant gloves

Step#1: Prepare the Fabric

First, remove the dust or lint from the fabric. To pre-press the fabric and to remove any moisture and wrinkles, place it on the heat press machine and apply light pressure at a low temperature around 300°F or 150°C for 5-10 seconds.

Step#2: Align the Transfer Film

Place the DTF transfer film with the printed design face down onto the fabric. Place the design correctly according to your desired placement. You can also use heat-resistant tape to secure the edges of the transfer film to the fabric.

Step#3: Heat Press Settings

Now you need to adjust the heat press machine to the recommended temperature for DTF transfers, usually between 320°F to 350°F (160°C to 175°C). Set the timer on the heat press for 10-15 seconds. The exact time may vary depending on the specific DTF film and fabric being used, so refer to the manufacturer's guidelines.

Step#4: Apply the Transfer

Place a Teflon sheet or parchment paper over the transfer film to protect it from direct contact with the heat press plate. Close the heat press and apply pressure for the set time. After the timer goes off, carefully open the heat press and remove the fabric.

Step#5: Peel the Transfer Film

Wait until the fabric cools down for a few seconds, but not completely. DTF transfers are typically peeled warm or hot. Peel the film by starting from one corner, and gently peel away the transfer film. Peel slowly and steadily to ensure the design transfers completely to the fabric.

Ending Note

So, here is everything you need to know about the direct-to-film printing method. You can now easily find your favorite DTF printed apparel or any merchandise after learning about its benefits.

You can even get the film and apply it yourself using this easy method. For businesses, this trend is amazing for marketing purposes and for starting up the business. I hope this guide will help you a lot! Cheers!